A Detailed Guide on Safety and Security of

Mar 20, 2024 · An in-depth guide to ensure the safety and security of the battery pack. Find out the potential hazards that can be detrimental to the battery''s life

Battery Design Explained: From Prototyping to Certification

Mar 20, 2025 · Learn how to design efficient, compliant battery packs for drones, robotics, medical devices, and e-mobility. Explore chemistries, BMS, certification, performance

Automotive Battery Pack Standards and Design

Apr 7, 2025 · Abstract The latest advancements and near-future trends in automotive battery packs, underlying regulatory compliance, and performance requirements are presented in this

Power Battery Pack Design Process

Jun 28, 2024 · Design the physical structure of the battery pack, including battery arrangement, connection methods, thermal design, etc. Design the packaging structure and protection

Battery Pack Design: Safety, Storage & Power

Feb 19, 2025 · Creating a battery pack requires careful planning to ensure safety, efficient energy storage, optimal power delivery, and thermal management. The design of your energy storage

Multi-objective optimization of EV battery packs:

Jun 28, 2025 · With the rapid development of electric vehicles and energy storage systems, traditional battery pack designs often encounter multi-objective conflicts. Optimizing the battery

Safety of Power Battery Systems – Comprehensive

May 27, 2025 · In the context of global energy transformation and growing environmental concerns, the new – energy vehicle industry is witnessing a remarkable boom. This growth is a

Battery Pack Design: Safety, Cost, and Performance

Mar 10, 2024 · The battery pack design must consider potential abuse situations like short circuits, overcharge, and penetration, ensuring safety and preventing thermal runaway in lithium-ion

Design, Optimization, and Analysis of Electric vehicle

Jun 8, 2022 · Choosing the right cooling mechanism for a lithium-ion battery pack for electric vehicles and developing an appropriate cooling control plan to maintain the heat contained

A Guide to Lithium-Ion Battery Safety

Jun 11, 2019 · Safety characteristics vary by Li-ion electrochemistry Overcharged (delithiated) positive can become unstable Passivation layer (SEI) can break down above 100°C

Uncertainty bottom impact optimization of power battery pack

Aug 1, 2024 · In the design process of electric vehicles, ensuring structural safety is crucial. Electric vehicles equipped with an integrated power battery pack located at the bottom are

Battery Pack Design Considerations for Performance and Safety

1 day ago · At the conclusion of our webinar, Custom Battery Pack Design Considerations for Performance and Safety, we had several questions submitted to our presenter, Battery

Custom Battery Pack Designer & Engineer Solutions

We provide everything from a single-cell battery pack with a safety circuit, to more complex multi-cell packs requiring BMS, and charging circuits, ATE, automated testing requirements, and

How to Design the Internal Structure of Lithium Battery Packs for Safety?

Jul 18, 2025 · By understanding the key considerations and best practices for designing the internal structure of lithium battery packs for safety and following the manufacturer''s

Battery Pack Design: Safety, Cost, and Performance

Mar 10, 2024 · Designing an EV battery pack involves carefully balancing various requirements. Understanding these mechanical, safety, maintenance, and cost considerations is critical for

The Shift to Custom Battery Solutions: Why Standard Power Packs

Mar 20, 2025 · Design and Prototyping – Creating battery packs that fit the size and performance requirements. Testing and Safety Checks – Ensuring the battery meets industry standards and

How will new safety standards impact custom battery design

5 days ago · New battery safety standards in 2025 will significantly reshape custom battery design through stricter thermal management requirements, enhanced testing protocols, and

Best Practices for Designing Lithium Battery Packs

Mar 10, 2025 · In today''s industries, from robotics and medical devices to solar energy storage and electric mobility, lithium battery packs play a crucial role in ensuring reliable and efficient

6 FAQs about [Power battery pack safety design solution]

What makes a good battery pack?

Battery pack design is crucial for electric vehicles (EVs) and energy storage systems. A well-designed battery pack ensures efficiency, safety, and longevity. But what makes a great battery pack? It’s more than just batteries. It includes cooling systems, management electronics, and structural integrity.

Why is safety and quality of battery pack design important?

Safety and quality of battery pack design is critical as more complex applications require expert engineering to support the most demanding electrical and mechanical design requirements.

How do you design a battery pack?

Designing an efficient and reliable battery pack involves multiple engineering considerations. The following key factors influence performance, safety, and durability. Voltage (V): Total voltage increases when cells are connected in series. Capacity (Ah): Total capacity increases when cells are connected in parallel.

What is a battery pack?

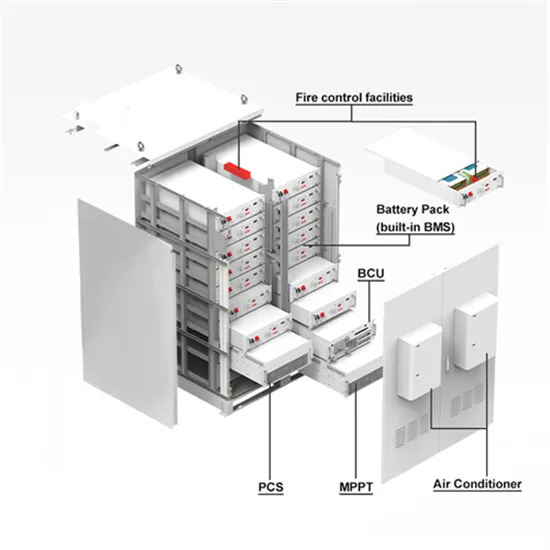

A battery pack is more than just a collection of cells—it is a sophisticated system designed to store and deliver energy safely and efficiently. Below, we break down the key components of a battery pack and their functions. A battery pack consists of several interconnected parts, each playing a vital role in energy storage and power delivery:

What is a high-capacity lithium-ion battery pack?

For EVs, high-capacity lithium-ion packs offer efficiency and longevity. A well-designed battery pack improves safety, durability, and efficiency. As technology advances, AI-driven design and structural integration will shape the future of energy storage.

What are the parts of a battery pack?

A battery pack consists of several interconnected parts, each playing a vital role in energy storage and power delivery: Battery Cells – The core energy storage units. Battery Management System (BMS) – Regulates voltage, temperature, and safety. Cooling System – Prevents overheating and maintains efficiency.

Learn More

- Energy storage battery pack safety design

- Power battery pack environmentally friendly design

- Battery Pack product design

- Sao Tome and Principe power battery pack

- Design of power storage solution in Laos

- Peru ups power lithium battery pack

- Albania Power Lithium Battery Pack

- Which brand of power lithium battery pack is good

- Huawei Croatia power battery pack

Industrial & Commercial Energy Storage Market Growth

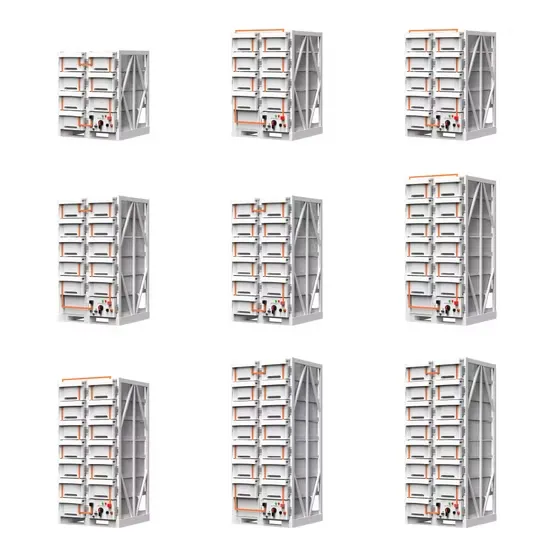

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.