Pack Sizing and Requirements

Jul 4, 2025 · We also need rapidly need to consider the Application as this has a significant impact on the battery pack. Land based transport Stationary storage Marine Aerospace Rail

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · Liquid-cooled battery pack design is increasingly requiring a design study that integrates energy consumption and efficiency, without omitting an assessment of weight and

Automotive Battery Pack Standards and Design

Apr 7, 2025 · Battery packs are key components of electric vehicles (EVs) because they operate as the main power supply. Despite recent advancements, further improvements are required

Review article Review on influence factors and prevention

Nov 20, 2023 · In order to address the above-mentioned challenges of battery energy storage systems, this paper firstly analyzes the factors affecting the safety of energy storage plants,

Dual-gate design enables intrinsic safety of high-energy batteries

Jun 1, 2024 · Moreover, such design has little side effect on the electrochemical performance of batteries. The dual-gate design breaks the bottleneck for the safety design of high energy

Designing Safe and Effective Energy Storage Systems: Best

Dec 2, 2024 · Introduction Battery energy storage systems (BESS) are vital for modern energy grids, supporting renewable energy integration, grid reliability, and peak load management.

Innovations in Traction Battery Pack Design for Enhanced Safety

Nov 26, 2024 · Effective thermal management is critical to the safety of EV battery packs. Overheating can trigger thermal runaway, a chain reaction that leads to catastrophic failure.

The Handbook of Lithium-Ion

Aug 16, 2025 · The Handbook of Lithium-Ion Battery Pack Design This page intentionally left blank The Handbook of Lithium-Ion Battery Pack Design Chemistry, Components, Types and

Battery Pack Design: Safety, Cost, and Performance

Mar 10, 2024 · This article explores the key considerations for designing a battery pack for electric vehicles (EVs), focusing on four crucial aspects: mechanical, safety,

Effects of thermal insulation layer material on thermal

Jan 15, 2024 · The safety accidents of lithium-ion battery system characterized by thermal runaway restrict the popularity of distributed energy storage lithium battery pack. An efficient

Designing Safe and Effective Energy Storage Systems: Best

Dec 2, 2024 · Building a safe and effective battery energy storage system hinges on meticulous planning, advanced technology selection, and rigorous safety protocols. By prioritizing

DelftX: Battery Management Systems (BMS) and Pack Design

Aug 14, 2025 · Learn how to effectively manage battery safety and lifecycle in battery pack design. Learn about applications of Battery Management Systems (BMS) in electric vehicles,

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Designing a Lithium-Ion Battery Pack: A Comprehensive Guide In recent years, the demand for efficient and powerful energy storage solutions has surged, primarily driven by

Energy Storage System Design: Balancing Safety

5 days ago · Engineers and designers face a threefold challenge: ensuring safety, maximizing performance, and lowering costs. Each of these dimensions interacts with the other,

Design approach for electric vehicle battery packs based on

Jan 30, 2024 · This work proposes a multi-domain modelling methodology to support the design of new battery packs for automotive applications. The methodology allows electro-thermal

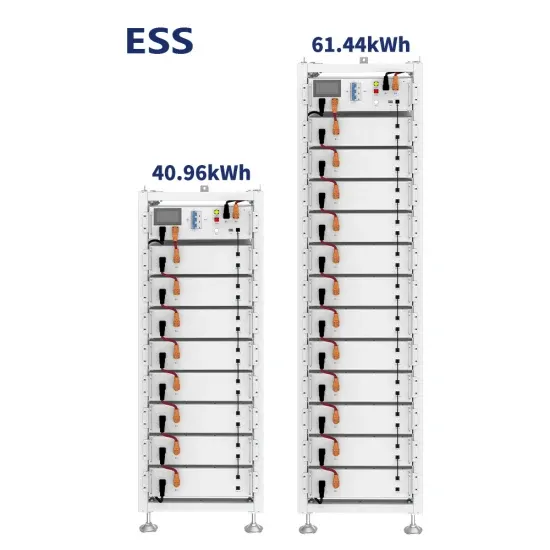

Battery Module vs Pack: Differences for Energy

Dec 29, 2023 · Delve into the distinctions between battery modules and packs. Gain insights into performance metrics and considerations for efficient energy

A review of battery energy storage systems and advanced battery

May 1, 2024 · Lithium batteries are becoming increasingly important in the electrical energy storage industry as a result of their high specific energy and energy density. The literature

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · The target concerns electric and hybrid vehicles and energy storage systems in general. The paper makes an original classification of past works defining seven levels of

Enhancing lithium-ion battery pack safety: Mitigating

Jul 1, 2024 · Enhancing lithium-ion battery pack safety: Mitigating thermal runaway with high-energy storage inorganic hydrated salt/expanded graphite composite

Battery Pack Thermal Design, NREL (National Renewable

Aug 17, 2016 · Battery Pack Thermal Design Ahmad Pesaran National Renewable Energy Laboratory Golden, Colorado NREL/PR-5400-66960 NREL is a national laboratory of the U.S.

Key Design Principles for Battery Pack Structures in Energy Storage

Nov 25, 2024 · Designing battery packs for energy storage systems requires a comprehensive approach that integrates structural integrity, environmental adaptability, and safety

6 FAQs about [Energy storage battery pack safety design]

How to design a battery pack / system?

When designing a battery pack / system it is important to think about and describe the safety concept. This will allow you to understand and show the layers of safety designed in physically or into the control system. The first thing is to look at the specification of the individual battery cell as this will specify the limits of safe operation:

What makes a good battery pack?

Battery pack design is crucial for electric vehicles (EVs) and energy storage systems. A well-designed battery pack ensures efficiency, safety, and longevity. But what makes a great battery pack? It’s more than just batteries. It includes cooling systems, management electronics, and structural integrity.

How can battery packaging design improve battery safety?

A robust and strategic battery packaging design should also address these issues, including thermal runaway, vibration isolation, and crash safety at the cell and pack level. Therefore, battery safety needs to be evaluated using a multi-disciplinary approach.

What is liquid cooled battery pack design?

Liquid-cooled battery pack design is increasingly requiring a design study that integrates energy consumption and efficiency, without omitting an assessment of weight and safety hazards.

Why is a lightweight battery pack enclosure important?

The lightweight battery pack enclosure design is desirable for maintaining a long-range and having good safety. Xiong et al. studied a novel procedure that significantly reduced the weight of the battery pack by improving its crashworthiness.

What is a battery pack?

A battery pack is more than just a collection of cells—it is a sophisticated system designed to store and deliver energy safely and efficiently. Below, we break down the key components of a battery pack and their functions. A battery pack consists of several interconnected parts, each playing a vital role in energy storage and power delivery:

Learn More

- Energy storage battery home safety distance

- Fire extinguishing scheme design for battery energy storage system of communication base station

- Protection level of energy storage battery PACK

- Energy storage battery pack bms

- St George Energy Storage Pack Battery

- Energy storage battery pack for commercial use

- Chemical Energy Storage Battery Pack

- Czech household energy storage lithium battery pack

- Belarus Gomel Energy Storage Battery Pack Factory

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.