Explosion-proof new energy battery pack

In the automotive industry today, traditional New Energy / Electric Vehicle (NEV/EV) battery packs typically adopt steel-framed battery pack structures to meet various puncture-proof, explosion

Lithium-ion energy storage battery explosion incidents

Sep 1, 2021 · Utility-scale lithium-ion energy storage batteries are being installed at an accelerating rate in many parts of the world. Some of these batteries hav

Energy Storage Safety Strategic Plan

May 5, 2024 · The Department of Energy Office of Electricity Delivery and Energy Reliability Energy Storage Program would like to acknowledge the external advisory board that

Lithium battery safety explosion-proof cabinet test

A battery cabinet is a particular type of storage cabinet that reduces the risks associated with lithium-ion batteries. These innovative cabinets create a safer environment in which

Lithium ion battery energy storage systems (BESS) hazards

Feb 1, 2023 · There has been an increase in the development and deployment of battery energy storage systems (BESS) in recent years. In particular, BESS using lithium-ion batteries have

UL 1973: Batteries for Use in Stationary and Motive Auxiliary

May 15, 2024 · UL 1973 is the safety standard for battery systems used in stationary applications, such as energy storage systems. ESS units listed to UL 9540 standards must meet the

UL 9540: Energy Storage Systems and Equipment

May 15, 2024 · UL 9540 ensures that components work together as a system and can be installed without posing a risk to people or property. UL 9540 defines construction requirements to

Explosion diagram of energy storage cabinet

2.1 Introduction to Safety Standards and Specifications for Electrochemical Energy Storage Power Stations. At present, the safety standards of the electrochemical energy storage system are

Lithium-ion energy storage battery explosion incidents

Sep 1, 2021 · The lithium-ion energy storage battery thermal runaway issue has now been addressed in several recent standards and regulations. New Korean regulations are focusing

Effects of explosive power and self mass on venting

Jan 15, 2025 · Electrochemical energy storage technology has been widely utilized in national-level grid energy storage, enhancing grid system security and stability and facilitating the

Safety assessment of Mn-based lithium-ion battery: thermal

Feb 11, 2025 · Driven by the goals of carbon neutrality, electrochemical storage technologies play a vital role in supporting the integration of renewable energy and reducing dependency on

UL 9540: Energy Storage Systems and Equipment

May 15, 2024 · Electrochemical ESS are required to be subjected to fire testing in accordance with UL 9540A UL 9540A is a testing methodology for extreme abuse conditions to evaluate

Electrochemical energy storage system explosion

Are lithium-ion battery energy storage stations prone to gas explosions? Here, experimental and numerical studies on the gas explosion hazards of container type lithium-ion battery energy

electrochemical energy storage pack explosion-proof standard

design enclosure for LIB packs is generally constructed to be explosion-proof (IEC60079.1 Standard Such batteries have already been used commercially for energy storage while

Energy Storage Science and Technology

Aug 5, 2022 · With the widespread use of electrochemical energy storage, safety accidents in energy storage systems occur frequently. In the energy storage system, once the thermal

Explosion Control Guidance for Battery Energy Storage

4 days ago · Standard on Explosion Protection by Deflagration Venting [9]. To lay the groundwork for a complete understanding of the current explosion control guidance, NFPA 855, NFPA 68,

Review of electric vehicle energy storage and management

Sep 1, 2021 · The energy storage section contains the batteries, super capacitors, fuel cells, hybrid storage, power, temperature, and heat management. Energy management systems

Explosion-proof lithium-ion battery pack

Jun 15, 2022 · In this article, a thorough experimental and finite element analysis is conducted to illustrate the paramount design parameters and factors that need to be considered for safe

Mitigating Hazards in Large-Scale Battery Energy

Sep 19, 2022 · January 1, 2019 Experts estimate that lithium-ion batteries represent 80% of the total 1.2 GW of electrochemical energy storage capacity installed in the United States.1 Recent

TCSAE88-2018 English PDF

Aug 3, 2025 · 3.1 Electrochemical energy storage power station An electrochemical cell is used as an energy storage component for power storage, conversion and release. 3.2 Energy storage

锂离子电池储能集装箱爆炸危害数值模拟

Apr 25, 2023 · 关键词: 锂离子电池, 储能, 集装箱, 爆炸危害, 数值模拟 Abstract: With the continuous application scale expansion of electrochemical energy

Energy storage battery pack explosion

What causes large-scale lithium-ion energy storage battery fires? Conclusions Several large-scale lithium-ion energy storage battery fire incidents have involved explosions. The large explosion

what are the explosion-proof standards for electrochemical energy storage

Single-atom catalysts for electrochemical energy storage and The expedited consumption of fossil fuels has triggered broad interest in the fabrication of novel catalysts for electrochemical

Development of Explosion Prevention/Control Guidance for

Nov 6, 2023 · Both the exhaust ventilation requirements and the explosion control requirements in NFPA 855, Standard for Stationary Energy Storage Systems, are designed to mitigate hazards

Explosion-proof new energy battery pack

Electrochemical energy storage technology has been widely used in grid-scale energy storage to facilitate renewable energy absorption and peak (frequency) modulation [1].Wherein, lithium

What are the explosion-proof standards for

1. Introduction. Electrochemical energy storage technology has been widely used in grid-scale energy storage to facilitate renewable energy absorption and peak (frequency) modulation

Thermal conditions of the battery cell of an electrochemical energy

Apr 22, 2025 · The obtained theoretical results on the temperatures of the main elements of the storage battery cell using the developed electrochemical-thermalmodel are necessary for

White Paper Ensuring the Safety of Energy Storage

Apr 24, 2023 · Introduction Energy storage systems (ESS) are essential elements in global eforts to increase the availability and reliability of alternative energy sources and to reduce our

Explosion hazards study of grid-scale lithium-ion battery energy

Oct 1, 2021 · However, the combustible gases produced by the batteries during thermal runaway process may lead to explosions in energy storage station. Here, experimental and numerical

6 FAQs about [Electrochemical Energy Storage Pack Explosion-proof Standard]

Are electrochemical energy storage systems ul 9540 certified?

As a basis, electrochemical energy storage systems are required to be listed to UL 9540 per NFPA 855, the International Fire Code, and the California Fire Code. As part of UL 9540, lithium-ion based ESS are required to meet the standards of UL 1973 for battery systems and UL 1642 for lithium batteries.

What's new in energy storage safety?

Since the publication of the first Energy Storage Safety Strategic Plan in 2014, there have been introductions of new technologies, new use cases, and new codes, standards, regulations, and testing methods. Additionally, failures in deployed energy storage systems (ESS) have led to new emergency response best practices.

What are non-electrochemical energy storage deployments?

Summary of non-electrochemical energy storage deployments. Pumped hydro storage plants store and generate energy by moving water between two reservoirs at different elevations. Water is pumped into an upper reservoir for charging and then released through pipes into turbines for discharging.

What are the three pillars of energy storage safety?

A framework is provided for evaluating issues in emerging electrochemical energy storage technologies. The report concludes with the identification of priorities for advancement of the three pillars of energy storage safety: 1) science-based safety validation, 2) incident preparedness and response, 3) codes and standards.

How difficult is it to design an explosion control system?

The highly unpredictable nature of thermal runaway with the potential for propagation into a large-scale ESS fire can make designing explosion control systems quite challenging. For example, while the characteristics of a single cell failure are predictable, failure does not always scale predictably at the system level.

Are explosion-proof cells safe?

While the cells enclosed in an explosion-proof box are considered to be safe, there are reports that the thermal runaway propagation from a single cell will ignite the space within the enclosure to a pressure far beyond its limit [12,18,19].

Learn More

- Centralized electrochemical energy storage system

- Standard capacity of industrial energy storage cabinet

- Energy storage cabinet pp battery pack

- Sana Energy Storage Lithium Battery Pack Processing

- The latest voltage resistance standard for energy storage batteries

- Protection level of energy storage battery PACK

- Pack energy storage system

- Energy storage system battery pack

- Outdoor energy storage cabinet battery pack push device

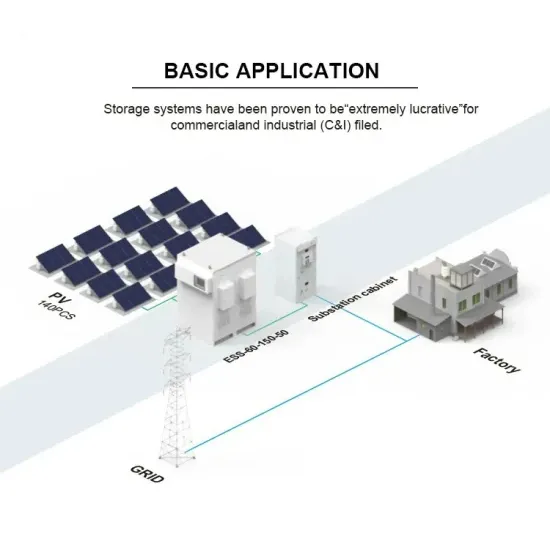

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.