DelftX: Battery Management Systems (BMS) and Pack Design

Aug 14, 2025 · Learn how to effectively manage battery safety and lifecycle in battery pack design. Learn about applications of Battery Management Systems (BMS) in electric vehicles,

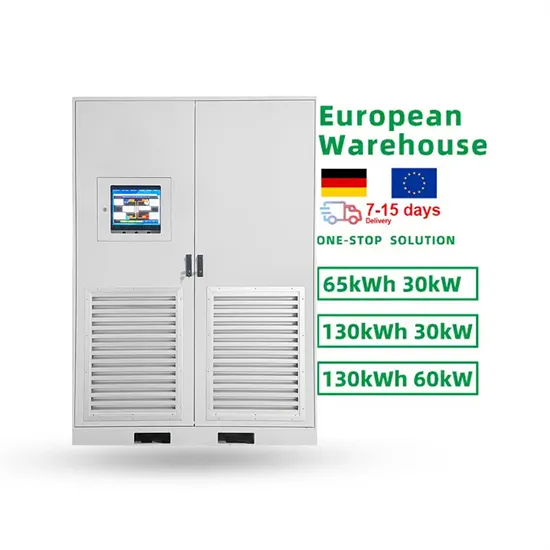

50 to 200kW Battery Energy Storage Systems

3 days ago · Discover the MEGATRON Series – 50 to 200kW Battery Energy Storage Systems (BESS) tailored for commercial and industrial applications. These systems are install-ready

Battery PACK Structure: Power vs. Energy Storage Designs

Energy storage battery PACKs, used in applications like grid-scale energy storage and home energy systems, prioritize long-term stability, cost-effectiveness, and safety. Key design

A complete analysis of battery cells, modules, battery packs and energy

Energy storage systems are categorized into household storage, commercial storage, and large-scale storage based on their application scenarios. This article provides a brief introduction to

Battery Cells, Modules, and Packs: Key Differences Explained

Apr 18, 2025 · Conclusion Understanding the intricate relationship between battery cells, modules, and packs is crucial for designing efficient, reliable, and high-performing energy

Understanding Battery Energy Storage Systems:

Aug 13, 2024 · A battery energy storage system consists of multiple battery packs connected to an inverter. The inverter converts direct current (DC) from the

Battery energy storage system modeling: A combined

Feb 1, 2019 · Battery pack modeling is essential to improve the understanding of large battery energy storage systems, whether for transportation or grid storage. It is an extremely complex

1MW Battery Energy Storage System

4 days ago · MEGATRONS 1MW Battery Energy Storage System is the ideal fit for AC coupled grid and commercial applications. Utilizing Tier 1 280Ah LFP battery cells, each BESS is

Life Cycle Assessment of a Lithium-Ion Battery Pack for

Dec 15, 2020 · Therefore, this study aims to add insight into the life-cycle assessment research field by conducting a cradle-to-grave lifecycle analysis for one lithium-ion battery pack intended

Detailed Application of Energy Storage Lithium

Oct 29, 2024 · As the demand for sustainable energy solutions continues to grow, home energy storage lithium-ion battery packs stand out as effective solutions

Battery Energy Storage Systems | Rolls-Royce

Battery energy storage systems play a vital role in this transition. Our mtu EnergyPack effectively integrates renewable energy sources like solar and wind power into the power network by

Battery Cells, Modules, and Packs: Key Differences Explained

Apr 18, 2025 · In modern energy storage systems, batteries are structured into three key components: cells, modules, and packs. Each level of this structure plays a crucial role in

Key Design Principles for Battery Pack Structures in Energy Storage Systems

Nov 25, 2024 · Designing battery packs for energy storage systems requires a comprehensive approach that integrates structural integrity, environmental adaptability, and safety

Battery energy storage system modeling: Investigation of

Jun 1, 2019 · Cell-to-cell variations can drastically affect the performance and the reliability of battery packs. This study provides a model-based systematic analysis of the impact of intrinsic

6 FAQs about [Energy storage system battery pack]

What is a battery energy storage system?

Battery Energy Storage Systems (BESS) have become a cornerstone technology in the pursuit of sustainable and efficient energy solutions. This detailed guide offers an extensive exploration of BESS, beginning with the fundamentals of these systems and advancing to a thorough examination of their operational mechanisms.

What is a battery pack?

A battery pack consists of multiple battery modules integrated to form a complete energy storage solution. Packs are engineered to deliver the required power and energy for specific applications. Modules: Combined in series and parallel to achieve the desired voltage and capacity.

What are the critical components of a battery energy storage system?

In more detail, let’s look at the critical components of a battery energy storage system (BESS). The battery is a crucial component within the BESS; it stores the energy ready to be dispatched when needed. The battery comprises a fixed number of lithium cells wired in series and parallel within a frame to create a module.

What is the difference between a battery pack and a module?

Mechanical Support: Modules are housed in sturdy frames to provide structural integrity and protect cells from physical damage. A battery pack consists of multiple battery modules integrated to form a complete energy storage solution. Packs are engineered to deliver the required power and energy for specific applications.

What are the components of a battery?

In modern energy storage systems, batteries are structured into three key components: cells, modules, and packs. Each level of this structure plays a crucial role in delivering the performance, safety, and reliability demanded by various applications, including electric vehicles, renewable energy storage, and portable devices.

What is a modular battery energy storage system?

Modular BESS designs allow for easier scaling and replacement of components, improving flexibility and reducing lifecycle costs. Designing a Battery Energy Storage System is a complex task involving factors ranging from the choice of battery technology to the integration with renewable energy sources and the power grid.

Learn More

- Paris photovoltaic energy storage battery pack price

- 2c energy storage battery pack

- Backup energy storage lithium-ion battery pack

- Outdoor energy storage cabinet battery pack push device

- Montevideo home energy storage battery pack prices

- Install battery pack in energy storage cabinet

- Energy storage battery pack for commercial use

- Bandar Seri Begawan custom made energy storage battery pack

- Belarus Gomel Energy Storage Battery Pack Factory

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.