ONEE SIGNS DEAL WITH INTERNATIONAL PARTNERS TO DECARBONIZE LAAYOUNE

International battery technology development trends The increase in battery demand drives the demand for critical materials. In 2022, lithium demand exceeded supply (as in 2021) despite

What are the new battery companies that have settled in Laayoune

A total investment of 10 billion yuan AVIC lithium battery ''''new power lithium-ion battery production line project'''' settled in Xiamen by:CTECHi 2021-09-19 With a total investment of 10 billion

What are the battery companies in Laayoune

Laayoune battery production equipment manufacturer Laayoune battery production equipment manufacturer As of 2019, the global battery marketplace was valued at $108.4 billion, and the

Laayoune lithium battery processing project cooperation

To be developed in three stages with AED 5 billion in investment by Titan Lithium, the plant will produce battery-grade lithium carbonate and lithium hydroxide for battery makers and electric

Laayoune lithium battery energy storage

This innovative lithium battery based power storage facility can be scaled to a 10GW/H potential, big enough to power the entire zone and keep the lights on Laayoune Back to Project Also see

Laayoune lithium battery processing project cooperation

Two leading lithium battery companies in China cooperate to Signed a 15-year strategic cooperation agreement with Lanxiao Technology, and jointly built a 10,000-ton lithium

Laayoune solid-state battery lithium sulfide production

Leveraging existing lithium-ion manufacturing. The cell manufacturing processes we have developed are already used globally for high volume traditional lithium-ion battery cell

Laayoune Battery Project Signing Process

of a lithium-ion battery cell * According to Zeiss, Li- Ion Battery Components – Cathode, Anode, Binder, Separator – Imaged at Low Accelerating Voltages (2016) Technology developments

Companies that make lithium batteries in Laayoune

The top 10 producers are all Asian companies. Currently, Chinese companies make up 56% of the EV battery market, followed by Korean companies (26%) and Japanese manufacturers

Laayoune low temperature lithium battery project investment

Why Do Lithium-ion Batteries Fear The Cold Charging or discharging at low temperatures has an irreversible effect on the lithium-ion battery, resulting in a dive in capacity and a serious safety

Companies that make lithium batteries in Laayoune

A state-owned company called CALB (China Aviation Lithium Battery Co., Ltd.) specialises in the design and production of lithium-ion batteries and power systems for a variety of uses,

Battery manufacturer at the Laayoune factory

Analysis of the Current Status of LiFePO4 Battery Manufacturing 1 · The global demand for lithium iron phosphate (LiFePO4 or LFP) batteries has been steadily rising, driven by their

Laayoune battery module production base

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, Industrial Robot Manufacturing Base.

Customized energy storage battery for Laayoune

Exide Technologies Leads The Way in Energy Storage Systems, Exide''''s Customized Energy Systems (CES), built on advanced lithium-ion battery technology, offering comprehensive

Laayoune energy storage battery brand

Choosing the best battery packs for solar storage will depend on your location, size of your solar system, and home energy needs. The top battery packs known by their brand names, Tesla

Chinese Cobalt Supplier Huayou to Invest $20 Billion in

Aug 10, 2023 · Chinese cobalt supplier Huayou unveiled plans to invest MAD 200 billion ($20 billion) in a factory dedicated to manufacturing batteries for electric vehicles in Morocco''s

Laayoune battery production equipment manufacturer

We cover the entire range of modern production solutions: from individual machines, for example for laboratory production, systems for pilot and small series production through to complete

MOROCCO''''S LAAYOUNE DESALINATION PLANT INCREASES PRODUCTION

What are the production steps in lithium-ion battery cell manufacturing? Production steps in lithium-ion battery cell manufacturing summarizing electrode manufacturing, cell assembly and

Laayoune energy storage module equipment production

Automatic lithium battery pack production line Our battery module automation production line stands at the forefront of advanced manufacturing technology, designed to streamline and

laayoune lithium-ion battery technology

Lithium-Ion Battery Technology This is because lithium-ion batteries are on track to power the transition to a sustainable energy system and transportation sector. Read our report to learn

Laayoune Battery Project Signing Process

PDF | The first brochure on the topic "Production process of a lithium-ion battery cell" is dedicated to the production process of the lithium-ion cell.... | Find, read and cite all the research

Latest energy storage battery export policy in Laayoune

What is the Laayoune power plant? The Laayoune power plant is currently fueled by heavy oil and features three high-performance GE Vernova 6B gas turbines with a total installed capacity of

Laayoune new energy battery construction started

It is a national high-tech enterprise integrating the research and development, design, production and sales of lithium-ion batteries and battery packs. We are committed to providing

Laayoune lithium battery industry layout planning

The first brochure on the topic "Production process of a lithium-ion battery cell" is dedicated to the production process of the lithium-ion cell. Both the basic process chain and details of

The Green Industrial Zone

6 days ago · Industrial steel and aluminum plant located in the zone to support the production of all manufacturing and construction needs for the Laayoune project. state of the art plant 100%

Learn More

- Dakar energy storage lithium battery assembly and production

- 12v41ah lithium battery pack production

- Production of 4 8v lithium battery pack

- Lithium battery production

- Single lithium battery production

- Lithium battery energy storage cabinet production

- 36v4a lithium battery pack production

- Laayoune distributed energy storage lithium battery

- Do you have a 14 volt lithium battery pack

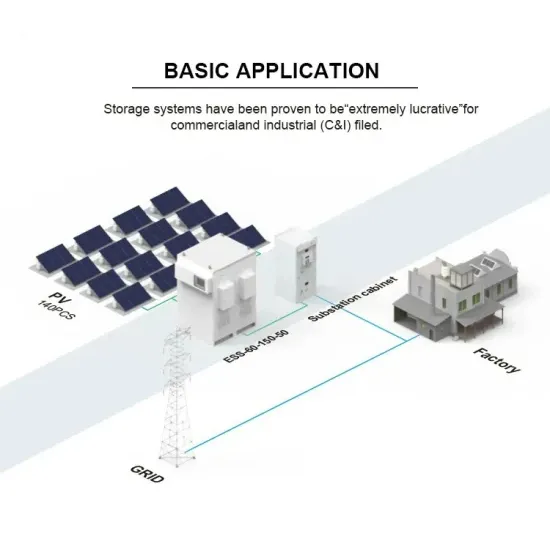

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.