Research on Heat Dissipation of Cabinet of Electrochemical Energy

Apr 1, 2025 · During the operation of the energy storage system, the lithium-ion battery continues to charge and discharge, and its internal electrochemical reaction will inevitably generate a lot

Journal of Electrical Engineering-, Volume Issue

Oct 27, 2024 · Safety is the lifeline of the development of electrochemical energy storage system. Since a large number of batteries are stored in the energy storage battery cabinet, the

Energy Storage Tank Heat Dissipation: The Cool Secret

The answer lies in energy storage tank heat dissipation – the unsung hero of modern power systems. As renewable energy solutions multiply faster than TikTok trends, managing heat in

Analysis of Influencing Factors of Battery Cabinet Heat Dissipation

The electrochemical energy storage system is an important grasp to realize the goal of double carbon. Safety is the lifeline of the development of electrochemical energy storage system.

battery energy storage cabinet heat dissipation method

Design and Optimization of Heat Dissipation for a High-Voltage Control Box in Energy Storage Abstract. To address the issue of excessive temperature rises within the field of electronic

Numerical Simulation and Optimal Design of Air Cooling

Jan 1, 2022 · Lithium-ion battery energy storage cabin has been widely used today. Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will

Thermal Simulation and Analysis of Outdoor Energy Storage

Jan 8, 2024 · Maintaining low and uniform temperature distribution, and low energy consumption of the battery storage is very important. We studied the fluid dynamics and heat transfer

Numerical Simulation and Optimal Design of Air Cooling Heat Dissipation

Jan 1, 2022 · Abstract Lithium-ion battery energy storage cabin has been widely used today. Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion

Liquid Gold Energy Storage and Heat Dissipation: The Future

Let''s face it: energy storage is the unsung hero of the renewable energy revolution. While solar panels and wind turbines steal the spotlight, it''s technologies like liquid gold energy storage

电化学储能系统电池柜散热的影响因素分析

The electrochemical energy storage system is an important grasp to realize the goal of double carbon. Safety is the lifeline of the development of electrochemical energy storage system.

电化学储能系统电池柜散热的影响因素分析<sup>*</sup>

Safety is the lifeline of the development of electrochemical energy storage system. Since a large number of batteries are stored in the energy storage battery cabinet, the research on their heat

Study on performance effects for battery energy storage

Feb 1, 2025 · In this section, the lithium ternary battery energy storage cabinet under the conditions of fixed air supply temperature and 2C discharge rate, and four inlet air flow rates of

Numerical Simulation and Optimal Design of Air Cooling Heat Dissipation

Jan 1, 2022 · Lithium-ion battery energy storage cabin has been widely used today. Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will

Analysis of Influencing Factors of Battery Cabinet Heat Dissipation

Safety is the lifeline of the development of electrochemical energy storage system. Since a large number of batteries are stored in the energy storage battery cabinet, the research on their heat

Principle of heat dissipation system of energy storage

this paper,the heat dissipation behavior of the thermal management system of the container energy storage system is investigated based on the fluid dynamics simulation method. The

Energy storage battery cabinet heat dissipation

Therefore, a lithium-ion battery energy storage cabin requires an efficient ventilation condition to ensure fire safety. This work investigates the effects of ventilation

Research on Heat Dissipation of Cabinet of Electrochemical Energy

During the operation of the energy storage system, the lithium-ion battery continues to charge and discharge, and its internal electrochemical reaction will inevitably generate a lot of heat.

Liquid Cooling Energy Storage System Design: The Future of

May 18, 2025 · Why Liquid Cooling Is Stealing the Spotlight in Energy Storage Ever wondered how your smartphone battery doesn''t overheat during a 4K video binge? Now imagine scaling

PCS-8812PB Liquid cooled energy storage cabinet

NR Electric Co. LtdPCS-8812 liquid cooled energy storage cabinet adopts liquid cooling technology with high system protection level to conduct fine temperature control for outdoor

Research on heat dissipation optimization and energy

Jun 21, 2024 · Uneven heat dissipation will affect the reliability and performance attenuation of tram supercapacitor, and reducing the energy consumption of heat dissipation is also a

Simulation of Active Air Cooling and Heat Dissipation of

Dec 31, 2023 · The advantages of Lithium-ion batteries can be concluded as specific energy and power, good cycling performance, and environmental friendliness. However, based on the

Experimental and numerical investigation of a composite

Mar 1, 2025 · Traditional air-cooled thermal management solutions cannot meet the requirements of heat dissipation and temperature uniformity of the commercial large-capacity energy storage

How to solve the heat dissipation problem of energy storage cabinet

How to solve the heat dissipation problem of energy storage cabinet Thermal Simulation and Analysis of Outdoor Energy Storage Heat dissipation from Li-ion batteries is a potential

Energy storage battery cabinet heat dissipation

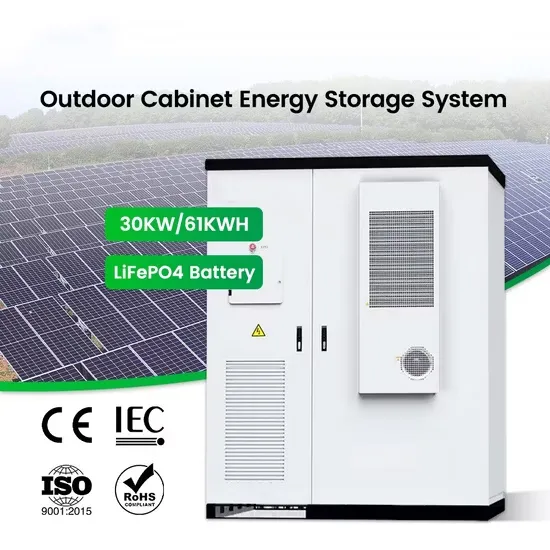

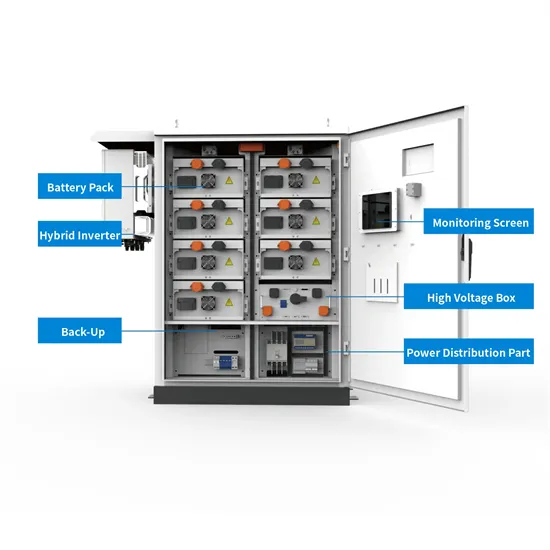

The 115kWh air cooling energy storage system cabinet adopts an "All-In-One" design concept, with ultra-high integration that combines energy storage batteries, BMS (Battery

Numerical study on heat dissipation and structure

May 1, 2024 · There are two categories for heat transfer methods: direct cooling and indirect cooling. Currently, the usage of indirect cooling is more common; however, heat transfer leads

Numerical Simulation and Optimal Design of Air Cooling Heat Dissipation

Jan 1, 2022 · Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence

Energy Storage Heat Dissipation Shell Welding: The Secret

Let''s face it: energy storage heat dissipation shell welding isn''t exactly dinner party chatter. But if you''re designing battery systems for EVs or grid storage, this topic is hotter than a

4 FAQs about [Heat dissipation of energy storage cabinet]

Does guide plate influence air cooling heat dissipation?

Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence of guide plate on air cooling. Firstly, a simulation model is established according to the actual battery cabin, which divided into two types: with and without guide plate.

Does guide plate influence air cooling heat dissipation of lithium-ion batteries?

Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will happen under extreme conditions. Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence of guide plate on air cooling.

What is lithium-ion battery energy storage cabin?

Lithium-ion battery energy storage cabin has been widely used today. Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will happen under extreme conditions. Effective thermal management can inhibit the accumulation and spread of battery heat.

How to improve the air cooling effect of battery cabin?

The air cooling effect of battery cabin was improved by adding guide plate. There is better consistency between the modules and the modules can operate at more appropriate environment temperature. Content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence.

Learn More

- How to choose the heat dissipation of the battery energy storage system of the communication base station

- Where does the heat of the energy storage battery cabinet come from

- What are the heat dissipation methods of new energy storage cabinets

- Solar cell cycle energy storage cabinet installation site

- Ranking of large energy storage cabinet custom manufacturers

- Energy storage system access control cabinet

- Seoul outdoor solar energy storage cabinet

- Tashkent produces energy storage cabinet batteries

- Energy storage cabinet battery price is half

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.