Monocrystalline vs N Type Solar Panels: 3 Distinctions

Jun 6, 2025 · Now let''s look at argon gas consumption in the production workshop. When pulling N-type silicon rods, the argon gas flow must be stabilized at 135-140L/min. If this value

N-type solar panels vs. Monocrystalline: which is more

Feb 27, 2025 · Leading paragraph: Are N-type monocrystalline solar panels truly more efficient than their P-type counterparts? Let''s break down the essential differences to determine which

Different Types Of Solar Panels In India: Cost,

Jul 22, 2025 · Explore 10 different types of solar panels in India, ranging from first-generation monocrystalline panels to the advanced types of solar panels for

What is the difference between Monocrystalline Perc and N

4 days ago · Monocrystalline PERC panels are simpler and less expensive to manufacture, while N-Type panels are made from a more complex composition but offer slightly higher efficiency

P Type Monocrystalline vs N Type Monocrystalline vs

Choosing between P-type monocrystalline, N-type monocrystalline, and polycrystalline solar panels depends on your specific energy needs, budget, and space constraints. P-type

What''s N-Type Technology and What Does it Mean for Solar?

Sep 27, 2022 · As Trina unveiled its new 210×210 mm monocrystalline N-Type i-TOPCon solar cell, it also announced that it set a new world record for efficiency levels of 25.5%.

Photovoltaic Cells for Sale: High-Efficiency Solar Solutions

1 day ago · 37% reorder rate 1097 interested customers Matches all 2/2 requirements For Topcon High Efficiency 182mm Bifacial Solar Cells N-Type PERC Monocrystalline Silicon for Topcon

Monocrystalline photovoltaic panels: what they are and their

Dec 11, 2024 · Monocrystalline photovoltaic panels are advanced devices designed to convert sunlight into electrical energy through a process called the photovoltaic effect. Their

Experimental comparison between Monocrystalline,

May 11, 2022 · PV cells are made from semiconductors that convert sunlight to electrical power directly, these cells are categorized into three groups depend on the material used in the

N-type Silicon Solar Cells: The Future of

Jul 21, 2021 · P-type cells suffer more from LID, which can be caused by oxygen impurities in monocrystalline p-type silicon cells reacting with the doped boron.

Top Photovoltaic Panels: High-Efficiency Solar Solutions for

1 day ago · Monocrystalline N-type TOPCon panels currently lead in efficiency (24-25.1%) and degradation rates (0.4-0.5%/year). They outperform polycrystalline and older PERC models in

Solar panel types: Comprehensive guide

Jun 15, 2025 · Types of solar panels: Overview Solar panels come in several types, each with unique solar panel materials and efficiency levels to suit different needs. Monocrystalline

Most efficient solar panels 2025

Jul 24, 2025 · What makes the most efficient solar panels? At present, silicon-based monocrystalline panels are the most efficient type available. However, modern monocrystalline

Monocrystalline vs N Type Solar Panels: 3 Distinctions

Jun 6, 2025 · Main differences: The efficiency of monocrystalline silicon panels is about 18%-22%, and the temperature coefficient is -0.38%/℃, while the efficiency of N-type panels can reach

Progress in n-type monocrystalline silicon for high

May 21, 2024 · Future high efficiency silicon solar cells are expected to be based on n-type monocrystalline wafers. Cell and module photovoltaic conversion efficiency increases are

6 FAQs about [Monocrystalline n-type photovoltaic panels]

What are monocrystalline solar panels?

Monocrystalline solar panels are renowned for their distinctive appearance and high efficiency. These panels are crafted from single-crystal silicon, a material known for its purity and uniformity. The manufacturing process involves cutting cylindrical silicon ingots into wafers, which ensures minimal crystal defects.

What are monocrystalline PERC & n-type solar panels?

Monocrystalline PERC (Passivated Emitter and Rear Cell) and N-Type (N-type Metal-Oxide-Semiconductor) solar panels are two advanced types of photovoltaic (PV) panels that are known for their high efficiency and performance.

What is the difference between monocrystalline and n-type solar panels?

Monocrystalline panels are known for their durability, often with warranties of 25 years or more. They tend to degrade at a rate of about 0.5% per year. N-type panels, with their advanced technology, boast even lower degradation rates, ensuring a longer effective lifespan and greater energy output over time.

Why are polycrystalline solar panels no longer made?

Polycrystalline cells and panels are no longer manufactured due to their lower efficiency, which peaked at just over 18%. In recent years, virtually all leading solar panel manufacturers worldwide have transitioned to producing more efficient solar panels using N-type HJT, TOPcon, or Back-contact cells.

Will n-type monocrystalline solar cells rise to 50% by 2031?

The International Technology Roadmap for Photovoltaic (ITRPV) report predicts that n-type monocrystalline solar cells will rise from 5% market share today to 50% by 2031: Source: ITRPV. Prices are tumbling, demand for renewable energy is growing and mainstream solar panels are pushing ever closer to their theoretical efficiency.

Are n-type solar panels better than single-crystal solar panels?

They are crafted from single-crystal silicon, making them not only more efficient but also aesthetically pleasing. On the other hand, N-type solar panels represent a leap in innovation, utilizing N-type silicon to push the boundaries of efficiency and performance, especially in high-temperature environments.

Learn More

- Supplier of monocrystalline photovoltaic panels

- Grenada monocrystalline photovoltaic module panels

- Flexible monocrystalline silicon solar photovoltaic panels

- Is it good for monocrystalline photovoltaic panels to have high power

- Price difference between monocrystalline and polycrystalline photovoltaic panels

- Zambia s annual electricity generation from monocrystalline photovoltaic panels

- Generation of electricity from monocrystalline photovoltaic panels in Casablanca Morocco

- Efficiency of monocrystalline and polycrystalline photovoltaic panels

- Are monocrystalline silicon photovoltaic panels afraid of corrosion

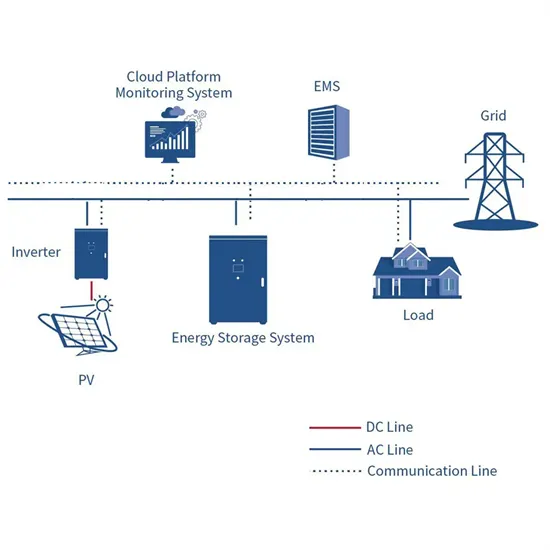

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.