Charging and discharging strategy of battery energy storage

Abstract: In view of the uncertainty of the load caused by the charging demand and the possibility that it may result in the overload of the charging station transformer during the peak period if

Energy Storage System Efficiency Calculation

Oct 24, 2024 · Understand the comprehensive efficiency of energy storage power stations and the factors affecting performance, including battery, power conversion system (PCS), transformer,

EV fast charging stations and energy storage technologies: A

Mar 1, 2015 · In the present paper, an overview on the different types of EVs charging stations, in reference to the present international European standards, and on the storage technologies for

Energy Storage System Efficiency Calculation

Oct 24, 2024 · According to GB/T 51437-2021 "Design Standards for Wind-Solar-Storage Combined Power Stations," the efficiency of an energy storage device should be calculated

Simulation and application analysis of a hybrid energy storage station

Oct 1, 2024 · A simulation analysis was conducted to investigate their dynamic response characteristics. The advantages and disadvantages of two types of energy storage power

Energy-storage configuration for EV fast charging stations

Feb 1, 2021 · Fast charging stations play an important role in the use of electric vehicles (EV) and significantly affect the distribution network owing to the fluctuation of their power. For exploiting

Modeling of fast charging station equipped with energy storage

Apr 1, 2018 · In order to reduce the power fluctuation of random charging, the energy storage is used for fast charging stations. The queuing model is determined to demonstrate the load

Definitions of technical parameters for thermal energy

Sep 15, 2024 · 2.1. Nominal power (Pnom.sys) Definition: The nominal power of a TES system is the design thermal power of the discharge. If relevant for the TES system, the nominal power

Charging station layout planning for electric vehicles based on power

Nov 15, 2023 · Operational details on both the supply and demand sides of the integrated energy system, including power generation, EV charging loads, charging and discharging loads of

Energy Storage: An Overview of PV+BESS, its

Jan 18, 2022 · Battery energy storage connects to DC-DC converter. DC-DC converter and solar are connected on common DC bus on the PCS. Energy Management System or EMS is

Measurement of power loss during electric vehicle charging and discharging

May 15, 2017 · Predominant losses occur in the power electronics used for AC-DC conversion. The electronics efficiency is lowest at low power transfer and low state-of-charge, and is lower

Onlin free battery calculator for any kind of battery

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Photovoltaic-energy storage-integrated charging station

Jul 1, 2024 · The results provide a reference for policymakers and charging facility operators. In this study, an evaluation framework for retrofitting traditional electric vehicle charging stations

Energy Storage: An Overview of PV+BESS, its

Jan 18, 2022 · Battery energy storage can be connected to new and existing solar via DC coupling Battery energy storage connects to DC-DC converter. DC-DC converter and solar are

Analysis of the storage capacity and charging and discharging power

Dec 15, 2020 · The main reason for considering energy storage should be making a profit for an energy storage company. This purpose of running a business also guarantees the rational use

Battery Energy Storage System Evaluation Method

Jan 30, 2024 · The method then processes the data using the calculations derived in this report to calculate Key Performance Indicators: Efficiency (discharge energy out divided by charge

A novel fault diagnosis method for battery energy storage station

Dec 15, 2023 · The cluster-to-cluster fault happens among out-going cables of different battery clusters which are gathered closely in the battery energy storage container to connect with the

Learning-based scheduling of integrated charging-storage-discharging

Mar 15, 2024 · The charging scheduling for a novel integrated station with the functions of charging, storage and discharging is initiated. Due to the fact that the battery can be charged

Energy management strategy of Battery Energy Storage Station

Sep 1, 2023 · The rapid and accurate estimation of the state of charge (SOC) of lithium battery is one of the key technologies of the battery management system, which can not only effectively

Charging and discharging optimization strategy for electric

Oct 1, 2023 · The electrification of urban transportation systems is a critical step toward achieving low-carbon transportation and meeting climate commitments. With the support of the Chinese

Battery Energy Storage for Electric Vehicle Charging

Sep 4, 2024 · Battery energy storage systems can enable EV fast charging build-out in areas with limited power grid capacity, reduce charging and utility costs through peak shaving, and boost

Grid-Scale Battery Storage: Frequently Asked Questions

Jul 11, 2023 · A battery energy storage system (BESS) is an electrochemical device that charges (or collects energy) from the grid or a power plant and then discharges that energy at a later

Optimal operation of energy storage system in photovoltaic-storage

Nov 15, 2023 · Optimizing the energy storage charging and discharging strategy is conducive to improving the economy of the integrated operation of photovoltaic-storage charging. The

Flexible energy storage power station with dual functions of power

Nov 1, 2022 · The high proportion of renewable energy access and randomness of load side has resulted in several operational challenges for conventional power systems. Firstly, this paper

Coordinated control strategy of multiple energy storage power stations

Oct 1, 2020 · Due to the disordered charging/discharging of energy storage in the wind power and energy storage systems with decentralized and independent control, sectional energy storage

How to Calculate the Charging and Discharging Efficiency of

Nov 15, 2024 · Initial Charging Energy = (System Rated Capacity × Depth of Discharge) ÷ (Battery Charging Efficiency × Rectification Efficiency of Energy Converter × Line Efficiency ×

6 FAQs about [Charging and discharging calculation of container energy storage power station]

How is energy storage capacity calculated?

The energy storage capacity, E, is calculated using the efficiency calculated above to represent energy losses in the BESS itself. This is an approximation since actual battery efficiency will depend on operating parameters such as charge/discharge rate (Amps) and temperature.

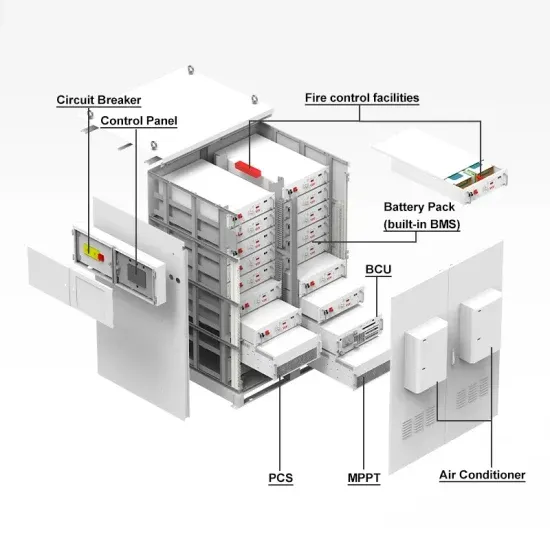

How many PCs units are in a 1 mw/2 MWh energy storage container?

Each 1 MW/2 MWh energy storage container includes two sets of 500 kW PCS, 2 MWh battery and corresponding battery management system. In order to simulate various situations, this paper assumes that PCS units 1–100 are divided into 5 groups, every 20 is a group.

How does battery energy storage connect to DC-DC converter?

Battery energy storage connects to DC-DC converter. DC-DC converter and solar are connected on common DC bus on the PCS. Energy Management System or EMS is responsible to provide seamless integration of DC coupled energy storage and solar. Typical DC-DC converter sizes range from 250kW to 525kW.

What is the difference between rated power capacity and storage duration?

Rated power capacity is the total possible instantaneous discharge capability (in kilowatts [kW] or megawatts [MW]) of the BESS, or the maximum rate of discharge that the BESS can achieve, starting from a fully charged state. Storage duration is the amount of time storage can discharge at its power capacity before depleting its energy capacity.

What is the application of energy storage in power grid frequency regulation services?

The application of energy storage in power grid frequency regulation services is close to commercial operation . In recent years, electrochemical energy storage has developed quickly and its scale has grown rapidly , . Battery energy storage is widely used in power generation, transmission, distribution and utilization of power system .

What is the maximum energy accumulated in a battery?

The maximum amount of energy accumulated in the battery within the analysis period is the Demonstrated Capacity (kWh or MWh of storage exercised). In order to normalize and interpret results, Efficiency can be compared to rated efficiency and Demonstrated Capacity can be divided by rated capacity for a normalized Capacity Ratio.

Learn More

- Huawei Home Power Station Energy Storage Charging and Discharging Times

- Charging pile small energy storage power station

- Kazakhstan Photovoltaic Energy Storage Power Generation Charging Station

- Does the charging and discharging of energy storage power stations affect the grid voltage

- Design of Capital Energy Storage Container Power Station

- How much power does a container energy storage power station have

- Energy storage power station container business model

- Charging and discharging of energy storage batteries in photovoltaic power stations

- Energy storage container power station effect

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.