Design Guide for Rooftop Solar

Oct 4, 2024 · Roof mounted PV Solar Panels are typically supported by racking systems which come in two basic forms. The first is a mechanically fastened system and the second, the

Roof Structure Design for Solar Panel Installation

Oct 28, 2023 · Therefore, it is crucial to consult with a qualified structural engineer to assess the roof''s design load and ensure that it can support the additional

Solar Power for Factory, Warehouse & Industrial

6 days ago · Why harness solar energy for your factory or industrial building roof? The roofs of factories are often the ideal place to install solar panels. As

Photovoltaic panel roof of factory building

Can solar panels be installed on a factory roof? The roofs of factories are often the ideal place to install solar panels. As factories are energy-intensive buildings,installing a solar PV system on

Design Guide for Rooftop Solar

Oct 4, 2024 · For a steel or wood low rise building, the relative additional weight from rooftop solar panels can add approximately 10% to the total factored design load of the roof structure.

Building Integrated Photovoltaic System (BiPV)

Feb 22, 2023 · Building Integrated System : BiPV Solar Panels forms the roof structure itself, therefore lesser materials required to be transported to site. The gap between panels and roof

(PDF) A Life-cycle Cost-benefit Analysis for

Dec 30, 2020 · In this research, three representative cities in China, with varying levels of solar radiation availability, are selected as typical external design

Solar Photovoltaic (PV) Ready Building Design Guidelines

Sep 2, 2022 · Introduction This document provides guidelines for the design of Kāinga Ora buildings that are to include solar PV systems. It is provided as a resource to the Kāinga Ora

10 buildings designed with integrated PV panels

Jun 6, 2023 · PV panels are commonly integrated into a roof''s structure — however, they can also be fitted as part of a building''s facade. PV roof tiles are solar panels designed to look and

Building-integrated photovoltaics (BIPV) in architectural design

Dec 1, 2011 · This paper discusses issues concerning BIPV in architectural design in China, including how to choose between BIPV and building-attached photovoltaics (BAPV), whether it

Steel Structure Factory Building

Mar 12, 2025 · The steel structure factory building can be designed in a large span and ample space, which is convenient for a flexible internal layout and use. The steel structure factory

Why Steel Structure for PV Panel is the Optimal Solution for

Jul 14, 2025 · Steel structure for pv panel supports heavy pv loads and adapts to rooftop, ground, or floating setups. This flexibility and adaptability ensure compatibility with different panel types

STRUCTURAL PERFORMANCE ANALYSIS AND DESIGN

Apr 21, 2019 · This project is about optimal structural design of solar panel supporting structure over a pitched roof of existing industrial building. In this study we are bringing forth the design

Steel Structure Factories & Flexible Photovoltaic Panels: The

Why Steel Factories Are Ideal for Flexible Photovoltaic Integration Did you know that steel structure factory buildings can reduce energy costs by 40-60% when equipped with flexible

Installation of photovoltaic panels in steel frame factory

1. Structural framework: This is the main support structure made of metal (often aluminum or galvanized steel), designed to hold the weight of the solar panels and withstand environmental

Discussion on the Application of Rooftop Photovoltaic Power

1. Structural framework: This is the main support structure made of metal (often aluminum or galvanized steel), designed to hold the weight of the solar panels and withstand environmental

Steel structure factory building for photovoltaic solar

Elevated Solar Panel Structures - The Optimal Solution. NBG Solar Structures provide custom-engineered elevated steel structures, designed to support solar panels used in all types of

Structural Engineering for Roof-Mounted Solar

Aug 18, 2025 · Top-rated consulting firms, that have the capacity to involve brilliant structural engineers, can facilitate economical and flowless design for

Rauta RoofSolar is a solar power station on a

Apr 6, 2023 · Ease of installation. The solar panels are fixed on the roof using a simple system of profiles and brackets specially designed for the installation of

6 FAQs about [Photovoltaic panels on the roof of steel structure factory building]

Can a steel structure roof be used for solar panels?

As a large area with good sunlight exposure, the steel structure roof is ideal for installing and constructing photovoltaic power generation facilities. Installing solar panels on steel buildings is particularly important to support the electricity consumption of metal buildings.

Can photovoltaic power stations be installed on steel structure roofs?

Installing photovoltaic power stations on steel structure roofs can produce significant economic benefits. The electricity enterprises use for production is generally industrial electricity, which has high electricity costs and faces uncertainty in power supply during peak periods.

Can solar photovoltaic panels be installed on roof of existing industrial building?

harnessed without the release of harmful pollutants to the environment. In our study solar photovoltaic panels are fi ed on roof of existing industrial building in Kolar district Karnataka. The main purpose of the analysis is to decide the structural sections and conn

How do roof mounted PV solar panels work?

Roof mounted PV Solar Panels are typically supported by racking systems which come in two basic forms. The first is a mechanically fastened system and the second, the more common of the two, is a ballast restrained system. The mechanically fastened system penetrates through the roofing membrane and can be used in pitched roofs and flat roofs.

How are photovoltaic panels installed?

When the steel frame, roof truss, and purlins meet the design requirements, and the roof panels are relatively rigid, this method is a more reasonable installation condition. The photovoltaic brackets are connected to the roof panels using connectors and fixed as close to the purlins as possible.

Can solar panels be used on steel buildings?

Solar panels on steel buildings mainly use photovoltaic arrays combined with steel structure building roofs and walls to generate solar power, which has outstanding energy and land-saving advantages.

Learn More

- Photovoltaic panels for steel structure roof

- Tirana photovoltaic panels for factory roof

- How to choose a manufacturer to install photovoltaic panels on the roof

- Bangkok brand photovoltaic panels wholesale factory direct sales

- Photovoltaic solar panels at Guinea-Bissau factory

- The distance between photovoltaic solar panels and the roof

- Photovoltaic panels are installed on the roof or on the roof

- 3000kw photovoltaic panel cost on factory roof

- Kingston roof mounted solar photovoltaic panels

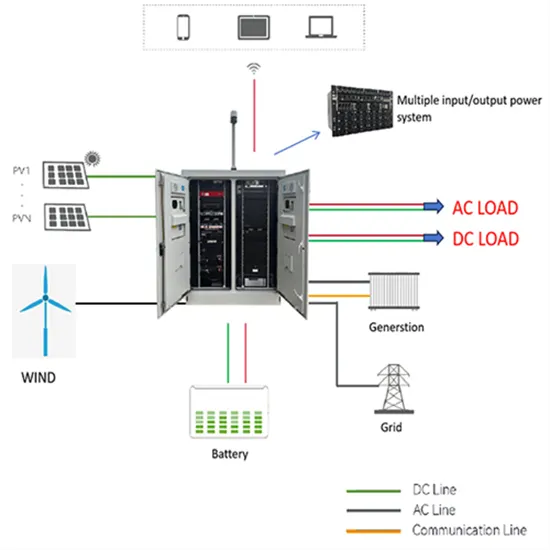

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.