Steel Profiles and Pipes in the PV Solar Industry: A Detailed

Jul 1, 2025 · Racking Systems: Steel profiles and pipes are commonly used to create the support structures or racking systems that hold solar panels in place. Ground-Mounted Racks: Thick

Carrying photovoltaic panels on colored steel tiles

The Valsa tiled roof mounting structure provides a non-penetrative solution for the installation of solar panels on commonly used tiles such as terracotta or concrete for domestic and

Design Guide for Rooftop Solar

Oct 4, 2024 · Designers must design roofing systems for the structural impact of existing, new and future solar panel installations. Roof mounted PV Solar Panels are typically supported by

Rooftop steel structure photovoltaic panels

Nov 30, 2021 · The following article covers various metal roof types and their associated racking methods, reviews industry-leading metal roof racking equipment, and offers best practices in

Steel Structure Photovoltaics: Versatile Installation for

Oct 11, 2024 · Steel structure photovoltaics are particularly suited for large-scale PV projects, which often require robust support systems to hold numerous solar panels securely. These

Design and Analysis of Steel Support Structures

Oct 8, 2020 · The ballasted footing mounts are the other option for the installation of PV solar panels; however, they cause a significant additional loading on the

Ground Mounted Structures for solar plants

Feb 7, 2018 · STEEL STRUCTURE FOR SOLAR PLANTS 2014 : BOISSIERES in FRANCE (30)– 10 MW – Foundation : Slab support – Structure : dual poles 2014 : BERROUTE &

Can You Use Solar Panels on Metal Buildings?

Solar panels also use flexible photovoltaic modules mounted on stainless steel roofs, emphasizing their structural stability and corrosion resistance. Alternative materials, including aluminum,

Why Steel Structure for PV Panel is the Optimal Solution for

Jul 14, 2025 · Steel structure for pv panel supports heavy pv loads and adapts to rooftop, ground, or floating setups. This flexibility and adaptability ensure compatibility with different panel types

Steel Frame Design for Rooftop Solar: When Engineering

The steel frame design for residential roof photovoltaic systems plays quarterback in this renewable energy game, coordinating between structural integrity, weather resistance, and

Steel in Renewable Energy: The Backbone of Solar Panels

Solar panels also use flexible photovoltaic modules mounted on stainless steel roofs, emphasizing their structural stability and corrosion resistance. Alternative materials, including aluminum,

Raised (floating) structure and variable PV panel

3 days ago · Includes all the hardware and fasteners, including the photovoltaic panel fasteners. The mounting system can adapt to the different sizes of the

Photovoltaic panel steel structure load requirements

The structure of a roof that supports solar photovoltaic panels or modulesshall be designed to accommodate the full solar photovoltaic panels or modules and ballast dead load,including

The relationship of PV and metal roofs:

Feb 15, 2022 · In the final entry of the three-part whitepaper series, S-5! and the Metal Construction Association take a look at the critical technical factors for

Concrete vs. Steel: Choosing the Right Material for Your

Any steel construction venture manufacturing Peb steel structure that is on the fence about signing up for solar is encouraged to go ahead and do so because this is the best time. Using

6 FAQs about [Photovoltaic panels for steel structure roof]

Can a steel structure roof be used for solar panels?

As a large area with good sunlight exposure, the steel structure roof is ideal for installing and constructing photovoltaic power generation facilities. Installing solar panels on steel buildings is particularly important to support the electricity consumption of metal buildings.

Can solar panels be used on steel buildings?

Solar panels on steel buildings mainly use photovoltaic arrays combined with steel structure building roofs and walls to generate solar power, which has outstanding energy and land-saving advantages.

Do rooftop solar panels add weight to a building?

For a steel or wood low rise building, the relative additional weight from rooftop solar panels can add approximately 10% to the total factored design load of the roof structure. However, when considered in light of the total building costs, this additional costs may prove to be minimal.

Can solar panels be used for roofing?

The following white paper provides recommendations on the structural design of roofing systems when considering solar panels. Solar power is produced by converting sunlight into electricity. The two major methods of converting sunlight into electricity are photovoltaics (PV) and concentrated solar power (CSP).

Can photovoltaic power stations be installed on steel structure roofs?

Installing photovoltaic power stations on steel structure roofs can produce significant economic benefits. The electricity enterprises use for production is generally industrial electricity, which has high electricity costs and faces uncertainty in power supply during peak periods.

Do rooftop solar panels affect a building?

The use of rooftop solar panels increases the superimposed dead load (SDL) of the roofing system and can have varying impact on a building depending on what material is being used for the structural system.

Learn More

- Photovoltaic panels for steel structure roof

- Tirana photovoltaic panels for factory roof

- Photovoltaic panels installed on the roof and paid

- Steel Plant Rooftop Photovoltaic Panels

- New photovoltaic panels installed on the roof

- Kingston roof mounted solar photovoltaic panels

- Installing photovoltaic panels on the roof can increase safety

- Photovoltaic panels and roof area ratio

- How many watts of photovoltaic panels can be installed on a 300 square meter roof

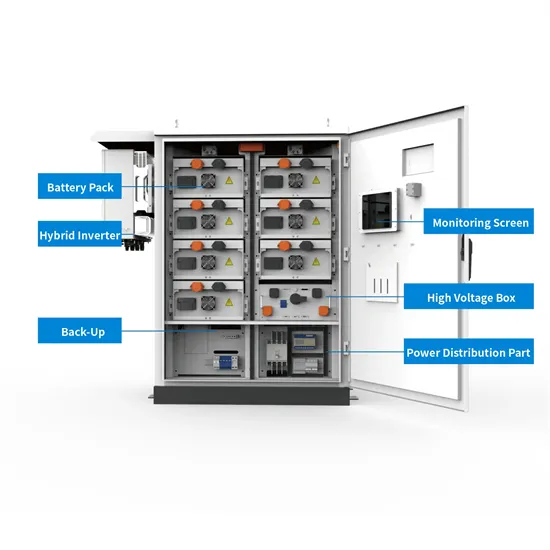

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.