EV Battery Conveyor Belts & Equipment | Intralox

Our technology offers gentle, touchless handling of delicate, high-voltage lithium-ion battery packs and modules, reducing risk and increasing throughput. Its high roller density accommodates

High-speed battery foil laser cutting improves

Jan 12, 2025 · The battery industry is driven by the need to balance technological innovation with reducing costs. Next-generation electric mobility vehicles

Semi-Automatic Conveyor Belt for Cylindrical & Prismatic Battery

This Semi-Automatic Conveyor Belt is designed for controlled and precise transportation of cylindrical and prismatic batteries in production lines. With a slow-speed mechanism, it

Why Are Speed Chain Conveyors Essential for Lithium Batteries

Discover the benefits of lithium battery speed chain conveyors, a revolutionary solution for modern automated production lines. These conveyors, also known as free-speed adjustable or

Automatic cylindrical lithium battery loader

The invention relates to an automatic cylindrical lithium battery loader, which belongs to the field of cylindrical lithium battery production equipment and comprises a rack, wherein a conveying

Semi-Automatic Cylindrical Prismatic lithium Battery module

Semi-Automatic lithium Battery module pack Production line high/slow speed chain Conveyor Belt The Semi-Automatic Conveyor Belt is designed for slow-speed transportation of cylindrical and

Semi-Automatic Conveyor Belt for Cylindrical & Prismatic Battery

The Semi-Automatic Conveyor Belt is designed for slow-speed transportation of cylindrical and prismatic batteries in production lines. Ideal for battery assembly and handling, this conveyor

Conveying and Handling Solutions for the EV Batteries

Batery Cell Case Manufacturing in Europe and USA CANLINE is dedicated to advancing battery cell case handling, utilizing cutting-edge technology to provide effective solutions. With a

Prismatic Lithium Battery Cell Assembly Line

Dec 4, 2024 · Prismatic battery cell assembly line, heat pressing, X-ray, ultrasonic welding, adapter, mylar wrapping, top cover welding, helium inspection, laser

Design of Automatic Packing Device For Cylindrical Lithium Battery

Apr 7, 2023 · increase the safety efficiency of lithium-ion batteries. the push out of the air cylinder to fix the position of the tray. conveyor belt, and then the battery reaches the corresponding

Battery automation solutions | Guangdong Sunkalead

The Semi-Automatic Conveyor Belt is designed for slow-speed transportation of cylindrical & prismatic batteries in production lines. battery assembly and handling, this conveyor ensures

Lithium Battery Industry Conveyor-Glory Intelligence

Lithium battery industry conveyor is adaptable, customizable, and adjustable to production line needs. In the industry, diverse products and processes prompt production lines to quickly

Semi-Automatic Conveyor Belt for Cylindrical & Prismatic Battery

Dec 9, 2024 · A semi-automatic conveyor belt is a specialized transport system designed to streamline the production of cylindrical and prismatic lithium batteries. It serves as an integral

Cylindrical Battery Tab Flattening Machine

6 days ago · The Battery Tab Flattening Machine uses a manual loading and unloading process combined with conveyor belt transportation. Workers place the wound battery cells onto the

Lithium battery industry conveyor belt

By using negative pressure. So, we need to perforated on the conveyor belt so that the wind can pass through the conveyor belt and act on the battery cells. Now, the issue of battery cell

Learn More

- Ecuador nca cylindrical lithium battery

- Cylindrical lithium battery diameter 25 height 65

- Cylindrical low temperature lithium battery

- Ethiopia cylindrical lithium battery

- Dili Large Cylindrical Lithium Battery

- How many volts is the largest cylindrical lithium battery in Albania

- Capacity cylindrical lithium battery

- What kind of cylindrical lithium battery is it

- Is the Warsaw lithium battery cylindrical

Industrial & Commercial Energy Storage Market Growth

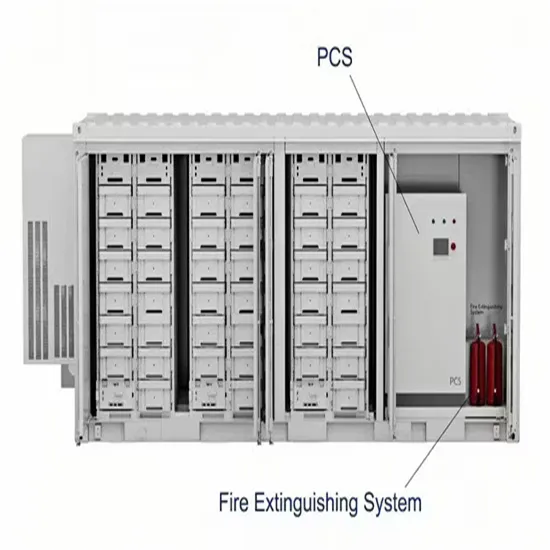

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

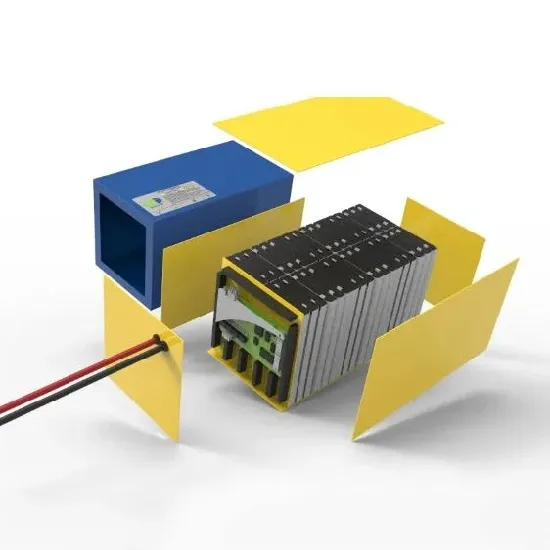

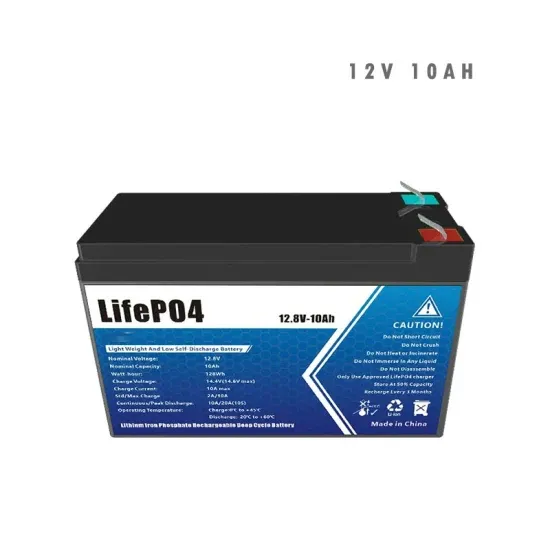

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.