What to Know for Your Custom Battery Storage Cabinet

May 21, 2025 · The design of a Custom Battery Storage Cabinet can be tailored with several key features to enhance performance and safety. Safety features such as fire-resistant materials,

Choosing the Right Battery Storage Cabinet: A

Jun 5, 2025 · Choosing the right battery storage cabinet is crucial to minimizing these risks. This comprehensive guide provides a detailed overview of safety,

A Comprehensive Guide to Telecom Battery Cabinets

Jul 24, 2024 · A comprehensive guide to telecom battery cabinets provides essential information on their features, types, selection criteria, installation tips, and innovations in technology.

Outdoor Battery Cabinets: A Smart Choice for Reliable

Dec 20, 2024 · The cabinet''s weather-resistant design prevents moisture, dust, and debris from entering the battery system, ensuring its longevity and reliability. Space Efficiency: Storing

How to design an energy storage cabinet: integration and

Jan 3, 2025 · This article will introduce in detail how to design an energy storage cabinet device, and focus on how to integrate key components such as PCS (power conversion system), EMS

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Choosing the optimal location for installing battery storage cabinets requires a careful balance of several factors. Indoor placement offers greater protection from

Designing Industrial Battery Rooms: Fundamentals and

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards. 1. Space

2018 Title Contents

Dec 20, 2022 · Some end users, however, may require or prefer that rack and cabinet designs be based on shake table test data. One of the principal differences between all of these seismic

UPS Battery Cabinets | 3D CAD Model Library | GrabCAD

Jul 25, 2022 · Heavy-duty, locking, 42U Premium Rack Enclosure Cabinet that accommodates all standard 19-inch rackmount equipment and ships fully assembled for quick and easy

6 FAQs about [Indoor battery cabinet design]

What is a typical battery cabinet?

A typical cabinet integrates batteries, racking and chargers into an indoor (NEMA 1 or IP21) or outdoor (NEMA 3R or IP54) rated enclosure. There are many different options and accessories available, making every system unique and built to your site-specific needs.

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

How do you choose a battery cabinet?

Again, the door should have a safe locking mechanism or latch. In more advanced battery cabinets, they may have alarm systems. Ventilation systems – they may integrate louvers. Depending on the enclosure design, the ventilation systems can be at the top or bottom section. Ventilation systems also help during the cooling process.

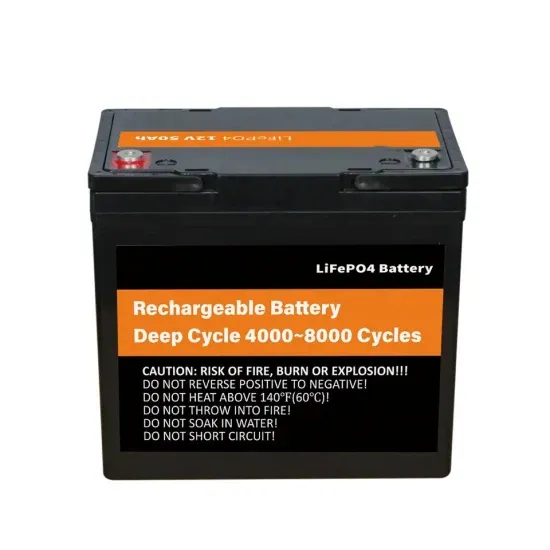

What type of batteries are used in energy storage cabinets?

Lithium batteries have become the most commonly used battery type in modern energy storage cabinets due to their high energy density, long life, low self-discharge rate and fast charge and discharge speed.

Do battery cabinet enclosures have a DIN rail?

Many enclosures have DIN rail. Electronic components –modern battery cabinet enclosures have sensors for smoke, shock, humidity, temperature, and moisture. These are safety measures to ensure the environment within the battery cabinet is safe. However, such enclosures are costlier.

Learn More

- Outdoor battery cabinet design requirements

- Scheme and design of energy storage battery cabinet

- Ottawa lithium battery energy storage cabinet design

- Yemen lithium battery energy storage cabinet design company

- Battery cabinet installation design instructions

- Energy Storage Battery Cabinet Design Method Site

- Lightweight design of new energy battery cabinet

- Guatemala City Outdoor Communication Battery Cabinet Design

- How big is the indoor battery cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.