Lightweight design and static strength analysis of battery

Sep 20, 2019 · In this paper, the lightweight design and static strength analysis of electric vehicle battery box were replaced by composite materials instead of traditional metal materials. Firstly,

A Critical Review on Lightweight Design of Battery Pack

Apr 2, 2021 · This paper reviews the multi-material battery enclosure design optimization, the multi- technologies, and a proficient Battery Management System (BMS) for compact battery

Topology Optimization and Lightweight Platform

Feb 8, 2024 · The arrangement of the power battery system and transmission system of new energy vehicles is quite different from that of traditional fuel vehicles, and the whole vehicle

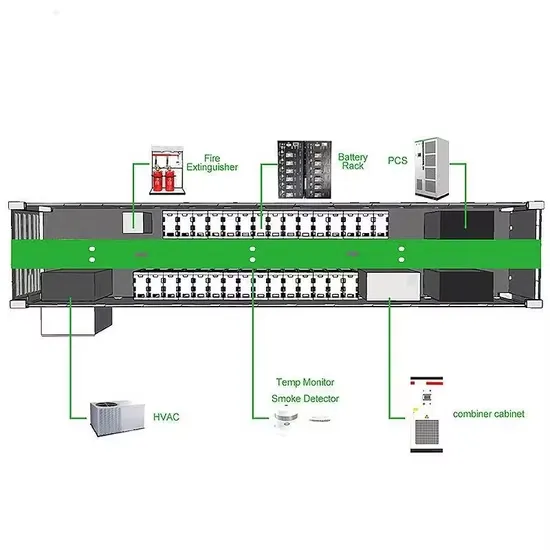

Standard Specifications for Lithium Battery Energy

AZE''''s 27U indoor battery rack cabinets painted with polyester powder, suitable for different brands lithium-ion batteries, it is the perfect solution for housing your Low Voltage Energy

How about new energy storage cabinet | NenPower

Jun 1, 2024 · 2. ENHANCED EFFICIENCY A primary consideration for any energy storage solution is efficiency, which directly influences user experience and economic viability. New

Optimizing Lightweight and Crashworthy Electric Vehicle Battery

Feb 17, 2025 · In electric vehicle (EV) design, the body surrounding the battery must effectively absorb impact, especially during crashes. This study aims to improve the crash performance

(PDF) Optimization design of battery bracket for

Jun 12, 2024 · As a consequence, it is particularly imperative to undertake lightweight design optimization for the battery bracket of new energy vehicles

Battery Storage Cabinets: The Backbone of Safe

Apr 11, 2025 · Explore the essential role of battery storage cabinets in modern energy systems, highlighting their design, safety features, and applications

Structural design principles of energy storage cabinets

How structural energy devices can improve energy conversion and storage performance? The structural designof energy devices can achieve satisfactory energy conversion and storage

Research on lightweight design of power battery cabin in

Dec 1, 2020 · The static analysis and constrained modal analysis are carried out for the battery cabin under two extreme conditions of bumpy sharp turn and bumpy emergency braking, and

Lightweight design of new energy vehicle power battery

This study conducts research on the lightweight design of new energy vehicle power battery packs based on the finite element analysis method. Firstly, a numerical model of the battery

Research on Lightweight Structure of New Energy Vehicle

Sep 7, 2023 · In the past few decades, research on battery pack boxes has mainly focused on functionality, and now there has been research on other aspects of performance, such as

Structural composite energy storage devices — a review

Mar 1, 2022 · Structural composite energy storage devices (SCESDs) which enable both structural mechanical load bearing (sufficient stiffness and strength) and electrochemical

Energy Storage Battery Pack Enclosure size optimization and

May 9, 2025 · In-depth analysis of ESS Battery Enclosure size matching and compatibility optimization technology, covering large-capacity battery cells, CTP integration, liquid cooling

Research on Electric Vehicle Battery Box Lightweight

May 25, 2017 · us of realizing automobile power electrification and developing electric vehicles. Battery box erweight, which affects the speed and mileage of the electric vehicle performance.

Lightweight Design of an Automotive Battery

Sep 26, 2021 · The battery packs are crucial components of electric vehicles and may severely affect the continue voyage course and vehicle safety. Therefore,

6 FAQs about [Lightweight design of new energy battery cabinet]

What is lightweight battery pack design?

Lightweight battery pack design is need of time to improve the range of the electric vehicle. Different Materials like composite and Honeycomb can be considered for battery pack enclosure lightweight design.

Which materials are used for battery pack enclosure lightweight design?

Different Materials like composite and Honeycomb can be considered for battery pack enclosure lightweight design. There is high potential to save weight of the structure by Honeycomb as it is light in weight and it has shock-absorbing capacity to avoid failure from shock loading.

Does battery pack enclosure optimize design?

The battery pack enclosure optimizes design shows enhanced performance as the maximum deformation diminished by 22.22% and mass of optimized enclosure is diminished by 11.61% .

Which load is considered for battery pack enclosure design?

Generic gravity loading, weight, and vibrational loading were considered for battery pack enclosure design. There was hardly any evidence found on actual test load cases and impact loads for design optimization .

Why is a battery pack enclosure important?

The battery packs are crucial components of electric vehicles and may severely affect the continue voyage course and vehicle safety. Therefore, design optimization of the battery-pack enclosure (BPE) is critical for enhanced mechanical and crashwrothiness performances.

What is improved battery pack for electric vehicles?

Lightweight design of battery box cover for new energy electric vehicles based on Optistruct topology optimization. This design aims to reduce weight and increase stiffness, as presented in the paper by Fengwu Shan, Dunhou Tan, and Jing Lin (2008) published in Times automotive.

Learn More

- New Energy Battery Cabinet Price

- New Energy Battery Cabinet Project Case

- Barbados new energy battery cabinet spraying

- Kazakhstan new energy battery cabinet base station power

- Estonia new energy battery cabinet stamping

- New Energy Battery Cabinet Working Environment

- New energy balances the entire battery cabinet

- New Energy Battery Cabinet Photovoltaic Measurement

- Number of batteries in the new energy battery cabinet

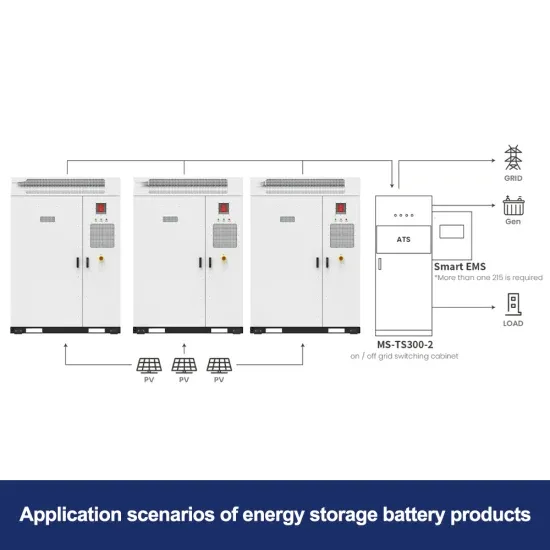

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.