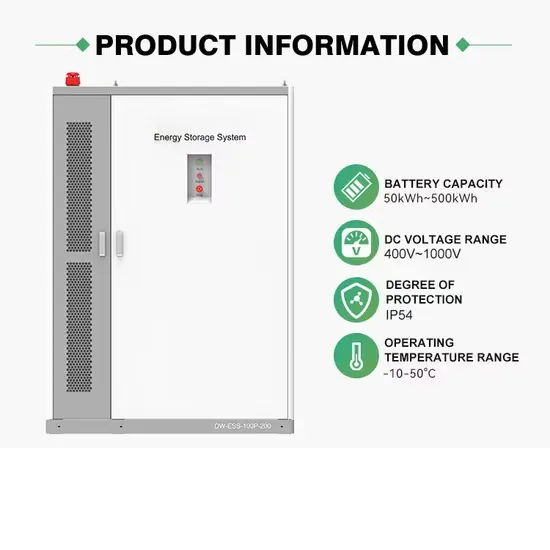

Liquid-cooled Energy Storage Cabinet

High Safety and Reliability • High-stability lithium iron phosphate cells. • Three-level fire protection linkage of Pack+system+water (optional). • Supports individual management for each cluster,

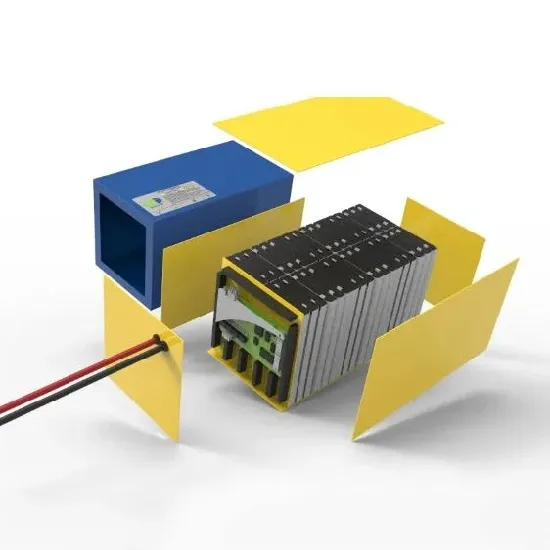

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

Energy Storage Cabinet Automation | HuiJue Group E-Site

The $47 Billion Question: Are We Maximizing Energy Storage Potential? While global investments in energy storage systems reached $47 billion in 2023, 62% of operators still report suboptimal

Energy Storage Cabinet Automatic Assembly Video: The

Ever wondered how those sleek energy storage cabinets powering your city get built? Spoiler: It''s not a group of elves working overtime. The real magic lies in energy storage cabinet automatic

How to design an energy storage cabinet: integration and

Jan 3, 2025 · This article will introduce in detail how to design an energy storage cabinet device, and focus on how to integrate key components such as PCS (power conversion system), EMS

Battery Energy Storage Manufacturing Automation | JR Automation

Jan 31, 2025 · At JR Automation, our capabilities extend far beyond battery module and EV powertrain assembly. We''re here to help you design automation solutions for battery energy

Energy storage cabinet assembly production line process

Energy storage cabinet assembly production line process What is the production process for chisage ESS battery packs? The production process for Chisage ESS Battery Packs consists

Energy storage cabinet assembly process

The assembly process is a vital step in the creation of high-quality 20ft energy storage containers. By choosing TLS Offshore Containers, you can be confident that your Sodium-Sulfur (Na-S)

Energy Storage Assembly Line: The Backbone of Modern

Jun 18, 2020 · Why Energy Storage Assembly Lines Matter in 2024 a factory humming with robotic arms, conveyor belts stacked with lithium-ion cells, and engineers fine-tuning battery

Automatic assembly principle of energy storage cabinet

With the core objective of improving the long-term performance of cabin-type energy storages, this paper proposes a collaborative design and modularized assembly technology of cabin-type

Automatic assembly of energy storage cabinet

Automatic assembly of energy storage cabinet As the photovoltaic (PV) industry continues to evolve, advancements in Automatic assembly of energy storage cabinet have become critical

Shanghai ZOE Energy Storage Technology Co., Ltd.

In the global energy transition, energy storage is key to integrating generation, grid, load, and storage systems. It enhances grid stability, addresses renewable energy intermittency, and

Industrial & Commercial Energy Storage Module Production:

4:Technical Features: High degree of automation, strong compatibility, high precision, and fast speed. Automated production, reduced manual positions, improved overall production

Module PACK line-Lithium battery PACK line-SHINHOP

Energy Storage Battery PACK The battery module production line requires higher precision and safety performance to ensure the performance and lifespan of the battery modules, improve

How to design an energy storage cabinet: integration and

Jan 3, 2025 · As the core equipment in the energy storage system, the energy storage cabinet plays a key role in storing, dispatching and releasing electrical energy. How to design an

Prismatic battery module semi-automatic assembly line

Battery manufacturer Lion Energy is developing a manufacturing line at its Utah facility for battery rack modules (BRM) and large energy storage cabinet assembly. The manual line will be used

Energy Storage Cabinet Automation | HuiJue Group E-Site

Thermodynamic Meets Algorithmic: The Automation Breakthrough Modern energy storage cabinet automation solutions employ multi-physics modeling that combines: 1. Electrochemical

Yawei sheet metal automation equipment has been

Mar 14, 2025 · Recently, Yawei shares successfully delivered sheet metal automation equipment to Anhui Huayuan Light Energy Technology Co., LTD., escorting the development of customer

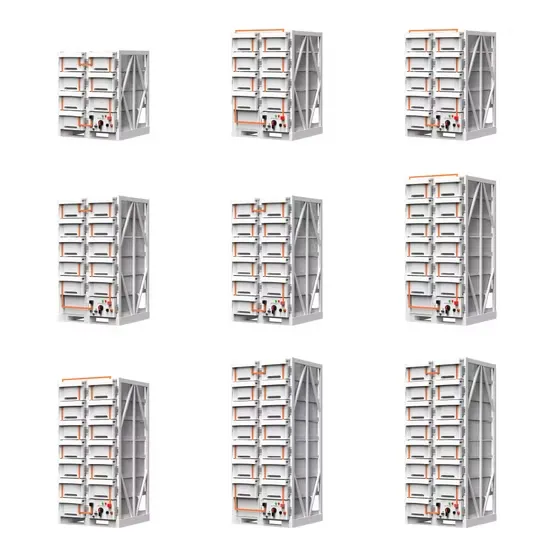

Energy Storage Cabinet Production Line

6 days ago · This production line is used for automatic assembly of energy storage cabinets. All single machine equipment and distributed systems interact with MES through a scheduling

6 FAQs about [Energy storage cabinet assembly automation system]

What is energy storage cabinet?

Energy Storage Cabinet is a vital part of modern energy management system, especially when storing and dispatching energy between renewable energy (such as solar energy and wind energy) and power grid. As the global demand for clean energy increases, the design and optimization of energy storage sys

Why do energy storage cabinets use STS?

STS can complete power switching within milliseconds to ensure the continuity and reliability of power supply. In the design of energy storage cabinets, STS is usually used in the following scenarios: Power switching: When the power grid loses power or fails, quickly switch to the energy storage system to provide power.

What type of batteries are used in energy storage cabinets?

Lithium batteries have become the most commonly used battery type in modern energy storage cabinets due to their high energy density, long life, low self-discharge rate and fast charge and discharge speed.

Why is energy storage important?

In the global energy transition, energy storage is key to integrating generation, grid, load, and storage systems. It enhances grid stability, addresses renewable energy intermittency, and supports a resilient, efficient, and sustainable energy infrastructure, enabling the seamless adoption of clean energy.

What is smart energy storage?

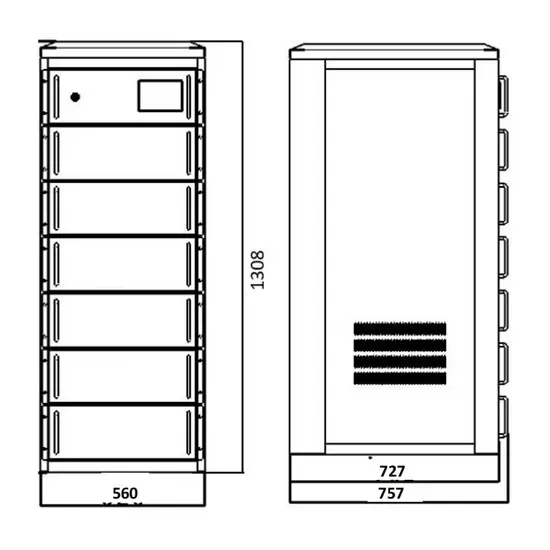

Standardized Smart Energy Storage with Zero Capacity Loss All-In-One integrated design, 1.76㎡ footprint, saving more than 30% of floor space compared to split type Low-voltage connection for AC-side cabinet integration, ensuring zero energy loss Four-in-one Safety Design: "Predict, Prevent, Resist and Improve"

What is a 30kW photovoltaic storage integrated machine?

Among them, the 30KW photovoltaic storage integrated machine has a DC voltage of 200~850V, supports MPPT, STS, PCS functions, supports diesel generator access, supports wind power, photovoltaic, and diesel power generation access, and is comparable to Deye Machinery. The Energy Management System (EMS) is the "brain" of the energy storage cabinet.

Learn More

- Liquid-cooled energy storage battery cabinet assembly

- Communication high voltage energy storage cabinet assembly plan and process

- Outdoor safe charging energy storage cabinet assembly

- Grid-side energy storage cabinet manufacturer

- Kampala energy storage cabinet battery EK production

- Madagascar stackable energy storage cabinet portable

- What is the price of Ankara commercial energy storage cabinet factory

- Energy storage cabinet battery rack

- Muscat Energy Storage Cabinet System

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.