Energy Storage Charging Detection Circuit: The Unsung Hero

Let''s face it – in our device-hungry world, energy storage systems are like oxygen tanks for smartphones and electric vehicles. At the heart of these systems lies the energy storage

Energy Storage Cabinet Fire Detection: Critical Safeguards

Why Fire Risks Are Skyrocketing in Battery Storage Systems You know, lithium-ion batteries power everything from smartphones to solar farms. But here''s the kicker: a single

Lithium battery energy storage detection | C&I Energy Storage

Articles related (80%) to "lithium battery energy storage detection" Suriname Lithium Battery Energy Storage Detection: Powering a Sustainable Future a country where 94% of the land is

Paris Capacitor Energy Storage Detection: The Hidden Hero

Feb 9, 2025 · The Nuts and Bolts of Capacitor Energy Storage Capacitors are like the sprinters of energy storage – quick to charge, faster to discharge. But here''s the catch: even Usain Bolt

Energy Storage Detection Gas Sensor Suppliers: The

Apr 5, 2020 · Why Your Energy Storage System Needs a Gas Detection Sidekick your state-of-the-art energy storage facility humming along smoothly... until an invisible threat like hydrogen

How to Protect Battery Energy Storage (BESS)?

Aug 16, 2023 · A structure containing energy storage systems that includes doors that provide walk-in access for personnel to maintain, test, and service the equipment and is typically used

Energy Storage Detection Work: The Backbone of Modern

Aug 23, 2023 · Ever wondered what keeps your solar-powered lights glowing at night or ensures your electric car doesn''t suddenly turn into a fancy paperweight? The unsung hero here is

How to Detect the Car Energy Storage Device: A Guide for

Nov 4, 2024 · Ever wondered what keeps your electric vehicle zooming silently down the highway? That''s right – the car energy storage device, whether it''s a lithium-ion battery pack

Energy Storage Equipment Detection: Why Your Batteries

Your fancy energy storage system is like that gym buddy who looks ripped but secretly eats donuts for breakfast. Without proper detection methods, you''re basically guessing when your

Energy Storage Cabinet: From Structure to Selection for

For renewable system integrators, EPCs, and storage investors, a well-specified energy storage cabinet (also known as a battery cabinet or lithium battery cabinet) is the backbone of a

How to Detect Battery Energy Storage: A Practical Guide for

Jan 8, 2023 · When someone types "how to detect battery energy storage faults," they''re not looking for textbook definitions – they want actionable solutions. Our data shows articles with

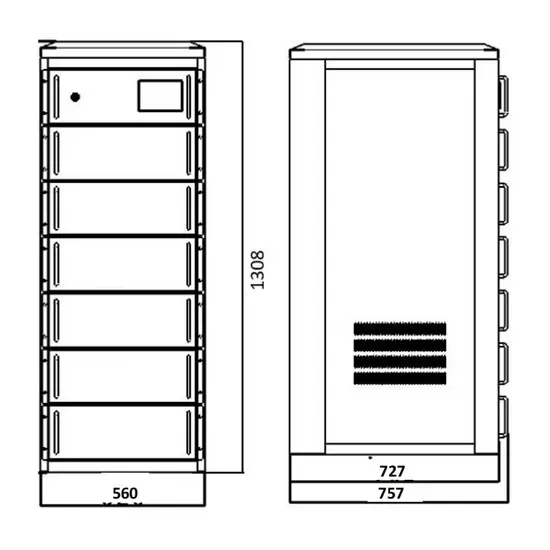

How to detect energy storage cabinet

The energy storage battery cabinet is a device used for storage and protection of electronic equipment in off-grid power stations. It is mainly used in various power generation systems

Hydrogen gas diffusion behavior and detector installation

Sep 1, 2023 · We conducted a gas diffusion behavior study and proposed a detection position optimization method through experiments and simulations. The gas warning effectiveness and

US Energy Storage Lithium Battery BMS Detection: Why It''s

Jun 5, 2019 · What''s the Buzz About BMS in Energy Storage? Let''s cut to the chase: if lithium-ion batteries are the rockstars of modern energy storage, then Battery Management Systems

Turkmenistan Power Grid Energy Storage Detection: The Future of Energy

Why Energy Storage Detection Isn''t Just a Fancy Buzzword Imagine Turkmenistan''s power grid as a giant Jenga tower. Remove one block (say, a sudden spike in demand), and the whole

Energy Storage Cabinet Inspection: A Critical Maintenance

Over 68% of battery failures in commercial systems occur due to overlooked inspection points, according to a fictitious but credible 2023 Gartner report on renewable energy infrastructure.

Cairo Home Energy Storage Detection Technology: Powering Smarter Energy

With Cairo''s energy storage market projected to grow 300% by 2027 [1], detection tech is becoming the backstage crew to renewable energy''s rockstar. Upcoming features include

Energy Storage Cabinet Sensor | HuiJue Group E-Site

Have you ever wondered what prevents energy storage cabinets from overheating in peak demand? With global grid-scale battery installations projected to reach 1.3 TWh by 2030

How to Detect Energy Storage Cabinets Like a Pro

Why Energy Storage Cabinet Detection Matters Now Ever wondered why utility companies are racing to install energy storage cabinets faster than Starbucks opens new locations? These

Study on early warning system for thermal runaway of

The top of the energy storage cabinet allows for timely and accurate detection of escaping gas and smoke. The findings of this study offer guidance for thermal runaway warning strategies in

Research on external and internal battery detection and

Oct 13, 2024 · In this work, an optical fiber sensing network is proposed for online monitoring of external and internal battery temperature and strain. The intrinsic relationship between the

How to design an energy storage cabinet: integration and

Jan 3, 2025 · As the core equipment in the energy storage system, the energy storage cabinet plays a key role in storing, dispatching and releasing electrical energy. How to design an

6 FAQs about [Energy storage cabinet detection]

Are gas detectors effective in energy-storage cabins?

The gas diffusion behavior and gas warning effectiveness in energy-storage cabins, and the installation strategy of gas detectors must be studied. This study addresses this gap by combining gas diffusion experiments in an energy-storage cabin with a finite element simulation analysis.

Can gas detectors be installed in energy-storage chambers?

The results of this study can provide guidance for the number and installation locations of gas detectors in energy-storage chambers. The specific contributions of this study are: A gas diffusion experiment was designed to study the TR warning effectiveness of H 2 detectors in an energy-storage cabin.

Do H2 detectors work in energy storage cabins?

A gas diffusion experiment was designed to study the TR warning effectiveness of H 2 detectors in an energy-storage cabin. A simulation model of gas diffusion was established and validated. The diffusion behavior of gas with and without convection was analyzed.

How many detectors can be installed in an energy-storage cabin?

It is reasonable to install three to five detectors in an energy-storage cabin. Shuang Shi a: Conceptualization, Data curation, Formal analysis, Methodology, Software, Validation, Writing-original draft. Nawei Lyu b: Methodology, Data curation, Methodology, Supervision, Investigation.

Can gas detectors prevent battery thermal runaway accidents?

The gas diffusion behavior is analyzed based on the experimental and simulation. The optimization method of gas detector installation is proposed. H 2 and CO are regarded as effective early safety-warning gases for preventing battery thermal runaway accidents.

Does the detector installation position affect the gas detection time?

The detector installation position significantly affects the gas detection time. We conducted a gas diffusion behavior study and proposed a detection position optimization method through experiments and simulations. The gas warning effectiveness and accuracy of the simulations were experimentally verified.

Learn More

- Energy storage cabinet detection

- Energy storage cabinet battery rack

- Solar energy storage cabinet coupled energy storage system

- How much is the price of energy storage cabinet container in Uruguay

- Large energy storage battery cabinet with the most power storage

- Energy storage cabinet Energy storage Charging pile Photovoltaic

- Liechtenstein heavy industry energy storage cabinet manufacturer

- 50kwh energy storage cabinet 2 2KWH report

- Home Micro Energy Storage Cabinet Solar Energy

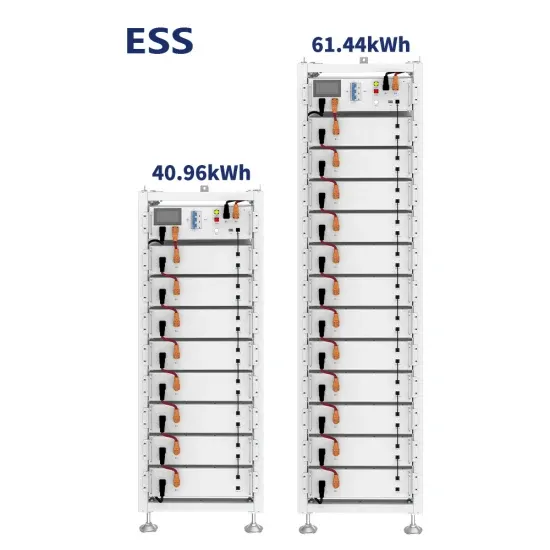

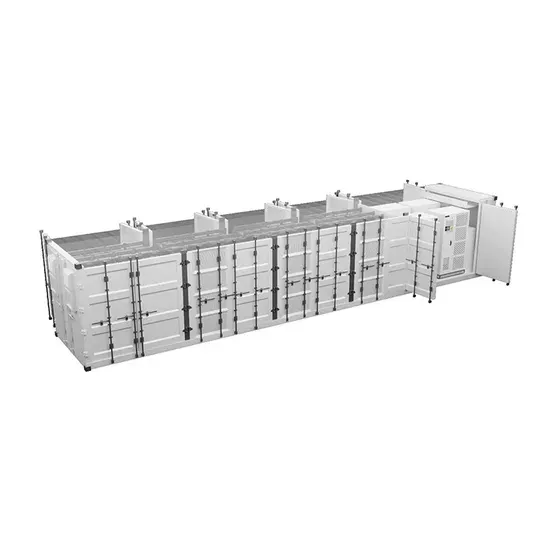

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.