FERC accepts ISO-NE''s longer-term transmission

Jul 10, 2024 · The process will allow the region to implement transmission system upgrades based on the results of longer-term transmission studies such as the

Energy Storage for Power System Planning and Operation

Jan 24, 2020 · In order to cope with the challenges brought by the large-scale REG integration to the planning and operation of power systems, the deployment of energy storage system (ESS)

2023 Regional System Plan

Mar 16, 2023 · Energy adequacy – insufficient fuel to support dispatchable resources and limited ability to charge battery energy storage systems Increased need for resource and demand

Optimal planning method for energy storage system based

May 20, 2024 · In this context, the theoretical research and methodological exploration of Energy Storage Systems (ESS), as a key component within the IES framework, have become

Transmission Planning Technical Guide

Introduction and Transmission This assumptions Transmission Planning used Planning in various Technical system G uide planning (the Guide) studies describes in England. the current An

Criteria and Conditions used in Interconnection Studies

PP5-6: Interconnection Planning Procedure for Generation and ETUs • 10.0 Additional Considerations for Generating Facilities that include Storage: The study of the discharging (i.e.

Navigating new benchmarking requirements for successful

Jul 2, 2024 · The power system is rapidly evolving, with an increasing amount of inverter based resources like variable renewable energy generators and battery energy storage systems. In

Participant Readiness Project Outlook

Last update: 08/06/2025 Summarized below are major projects that will bring changes to ISO New England systems and processes and may require action by your organization. Please review

6 FAQs about [Isone energy storage system field plan]

What is a storage-based energy system?

A storage-based energy system is understood to mean the use of one or more storage systems in an electrical supply structure consisting of generators and consumers. Efficient planning and control of such energy systems requires tools that minimize the economic costs of installation and operation of the systems involved.

When does an energy storage project start?

“The operations and maintenance phase of an en- ergy storage project begins when the system has been successfully commissioned and the owner has obtained approval to operate the system.

What should be included in a contract for an energy storage system?

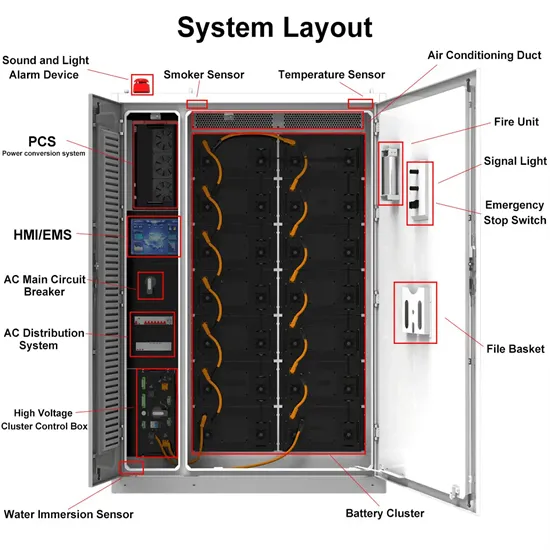

Several points to include when building the contract of an Energy Storage System: • Description of components with critical tech- nical parameters:power output of the PCS, ca- pacity of the battery etc. • Quality standards:list the standards followed by the PCS, by the Battery pack, the battery cell di- rectly in the contract.

What is a battery energy storage system (BESS) e-book?

This document e-book aims to give an overview of the full process to specify, select, manufacture, test, ship and install a Battery Energy Storage System (BESS). The content listed in this document comes from Sinovoltaics’ own BESS project experience and industry best practices.

How to compare battery energy storage systems?

In terms of $, that can be translated into $/kWh, the main data to compare Battery Energy Storage Systems. Sinovoltaics’ advice: after explaining the concept of usable capacity (see later), it’s always wise to ask for a target price for the whole project in terms of $/kWh and $.

What is nrgise plan & nrgise control?

Multi-use: Both NRGISE.plan and NRGISE.control support the multi-use of storage systems, so that several applications such as peak shaving, PV self-consumption optimization or arbitrage can be combined to maximize the return on investment.

Learn More

- Electric energy storage field reform plan

- Ngerulmud Battery Energy Storage Field

- Syria Photovoltaic New Energy Storage Field

- Honduras Home Energy Storage Field

- Overall energy storage plan

- New energy storage field capacity

- High-precision energy storage box customization plan

- Maintenance plan for battery energy storage system of communication base station in Azerbaijan

- Communication high voltage energy storage cabinet assembly plan and process

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.