Strategy of 5G Base Station Energy Storage Participating

Oct 3, 2023 · Finally, with the objective to minimize the power vacancy, the optimization model of the 5G base station auxiliary power system frequency response is established. Considering

Optimization Control Strategy for Base Stations Based on Communication

Mar 31, 2024 · With the maturity and large-scale deployment of 5G technology, the proportion of energy consumption of base stations in the smart grid is increasing, and there is an urgent

Commissioning and Maintenance Processes for Energy Storage Systems

Jan 3, 2025 · Proper commissioning and maintenance are critical to ensure these systems operate safely, reliably, and efficiently. Here''s a detailed guide to the key processes involved in

Battery Energy Storage System Integration and

In this paper, a BESS integration and monitoring method based on 5G and cloud technology is proposed, containing the system overall architecture, 5G key technology points, system

Optimization strategy of base station energy consumption

May 13, 2024 · This article focuses on the optimized operation of communication base stations, especially the effective utilization of energy storage batteries. Currently, base station energy

Optimal configuration for photovoltaic storage system

Oct 1, 2021 · The inner layer optimization considers the energy sharing among the base station microgrids, combines the communication characteristics of the 5G base station and the

Predictive-Maintenance Practices For Operational Safety

Oct 26, 2020 · This article advocates the use of predictive maintenance of operational BESS as the next step in safely managing energy storage systems. Predictive maintenance involves

Handbook on Battery Energy Storage System

Aug 13, 2020 · The Ni–MH battery combines the proven positive electrode chemistry of the sealed Ni–Cd battery with the energy storage features of metal alloys developed for advanced

BATTERY ENERGY STORAGE SYSTEMS

Nov 9, 2022 · Amp Alternating Current Battery Energy Storage System Battery Monitoring System Bill of Lading Containerized EnergyStorage System Commercial & Industrial Direct Current

Strategy of 5G Base Station Energy Storage Participating in the Power

Mar 13, 2023 · The proportion of traditional frequency regulation units decreases as renewable energy increases, posing new challenges to the frequency stability of the power system. The

Utility Battery Energy Storage System (BESS) Handbook

Oct 7, 2024 · Research Overview Primary Audience Utility project managers and teams developing, planning, or considering battery energy storage system (BESS) projects.

Selection and maintenance of batteries for communication base

This article focuses on the engineering application of the battery in the power supply system of the communication base station, and focuses on the selection, installation and maintenance of the

A Comprehensive Roadmap for Successful Battery Energy Storage System

Jun 10, 2025 · A Roadmap for Battery Energy Storage System Execution — ### Introduction The integration of energy storage products commences at the cell level, with manufacturers

What is base station energy storage | NenPower

Mar 11, 2024 · Base station energy storage refers to systems designed to store energy, primarily for telecommunications infrastructure, enabling reliable operation during power outages and

Guide to Regular Maintenance of Battery Energy

Oct 22, 2024 · Regular maintenance is essential to ensure the safety, efficiency, and longevity of battery energy storage systems. This article will introduce the

The business model of 5G base station energy storage

In terms of 5G base station energy storage system, the literature [1] constructed a new digital ''mesh'' power train using high switching speed power semiconductors to transform the

Battery Energy Storage Systems Report

Jan 18, 2025 · This information was prepared as an account of work sponsored by an agency of the U.S. Government. Neither the U.S. Government nor any agency thereof, nor any of their

6 FAQs about [Maintenance plan for battery energy storage system of communication base station in Azerbaijan]

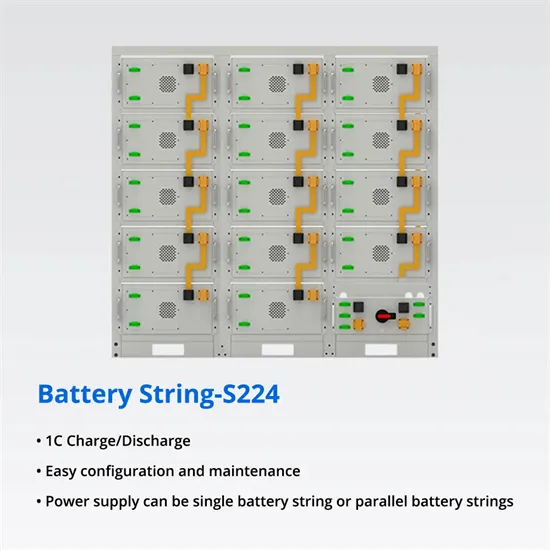

What are the guidelines for battery management systems in energy storage applications?

Guidelines under development include IEEE P2686 “Recommended Practice for Battery Management Systems in Energy Storage Applications” (set for balloting in 2022). This recommended practice includes information on the design, installation, and configuration of battery management systems (BMSs) in stationary applications.

What is a battery energy storage system (BESS)?

With the rapid development of renewable energy, Battery Energy Storage Systems (BESS) are widely used in power, industrial, and residential sectors. Regular maintenance is essential to ensure the safety, efficiency, and longevity of battery energy storage systems.

What is a battery maintenance check?

Annual Check: In-depth assessment of battery health, analyzing performance, and predicting battery life. As a key component of modern energy solutions, battery energy storage systems require regular maintenance to ensure long-term stable operation and extend their lifespan.

Can predictive maintenance help manage energy storage systems?

This article advocates the use of predictive maintenance of operational BESS as the next step in safely managing energy storage systems. Predictive maintenance involves monitoring the components of a system for changes in operating parameters that may be indicative of a pending fault.

Why should battery energy storage systems be maintained?

Battery energy storage systems can be affected by various factors during everyday use, such as ambient temperature, load changes, and battery aging. Regular maintenance helps detect potential issues, prevents sudden system failures, and ensures long-term stable operation.

How often should energy storage systems be maintained?

The required maintenance frequency may vary depending on the type of energy storage system. However, the following maintenance schedule is generally recommended: Monthly Check: Basic checks such as battery status, thermal management system, and BMS operation.

Learn More

- Maintenance of battery energy storage system for integrated communication base station in Belize

- Montevideo Integrated Communication Base Station Battery Energy Storage System Maintenance

- China s most remote communication base station battery energy storage system 100KWh

- Algiers communication base station flow battery energy storage

- How to connect the cylindrical energy storage cabinet of the communication base station battery energy storage system

- Jordan communication base station battery energy storage system battery

- A set of equipment is installed in the battery energy storage system of the communication base station

- Gaborone Communication Base Station Battery Energy Storage System New Communication

- Communication base station battery energy storage system 7900

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.