光伏逆变器基本指南

地点(总部):中国深圳 成立年份:2013 Primroot 是尖端专业 太阳能逆变器制造商 总部位于中国深圳高科技中心。凭借我们世界一流的研发团队的创新

An Overview of Photovoltaic Microinverters: Topology, Efficiency, and

Apr 25, 2019 · This paper presents an overview of microinverters used in photovoltaic (PV) applications. Conventional PV string inverters cannot effectively track the optimum maximum

Grid-connected photovoltaic inverters: Grid codes,

Jan 1, 2024 · The proliferation of solar power plants has begun to have an impact on utility grid operation, stability, and security. As a result, several governments have developed additional

Inverter Transformers for Photovoltaic (PV) power plants:

Dec 22, 2022 · In this paper, the author describes the key parameters to be considered for the selection of inverter transformers, along with various recommendations based on lessons

A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · In this review, the global status of the PV market, classification of the PV system, configurations of the grid-connected PV inverter, classification of various inverter types, and

微型光伏逆变器拓扑及相关技术研究综述

Mar 24, 2017 · Abstract In order to find the best solution to reduce costs and improve efficiency and reliability of mi-cro-inverter, topologies of micro-inverter in photovoltaic power generation

Inverters: A Pivotal Role in PV Generated Electricity

Dec 15, 2021 · Inverter: center of the system—increasingly becoming the brain, more features and capabilities (hybrid systems, safety, islanding, monitoring...) This work was authored by the

华为智能光伏官网-太阳能光伏发电站解决方案-光伏

华为智能光伏推出领先的户用光伏发电、户用光伏储能、工商业光伏发电、工商业储能电站、大型地面智能光伏电站建设的解决方案,华为光伏逆变器,储能、

AIT Austrian Institute of Technology

Oct 19, 2018 · New challenges for Low Voltage Distribution Grids not exceeding voltage limits, require Smart Inverters and Substations. Goal of this work: «Is the PV inverters Q(U) control

全球光伏逆变器数据库 | 易恩孚光伏产品名录

拥有详细分类的全球太阳能逆变器产品名录,您可以通过产品图片、详细参数、PDF和认证数据来查阅并对比.光伏逆变器产品名录 欢迎访问全球领先的光伏

STEVAL-ISV002V1, STEVAL-ISV002V2 3 kW grid

It consists of a high frequency isolated input power section performing DC-DC conversion and an inverter section capable of delivering sinusoidal current of 50 Hz to the grid. The system

光伏逆变器(PV Inverter) | 能源 | 工业设备 | 解决

光伏逆变器(PV Inverter) 为实现低碳社会,可再生能源的利用越来越广泛,太阳能发电系统的需求与日俱增。 为了将太阳能产生的电力高效传入电网,罗姆

光伏(PV) 逆变器设计,此设计使用太阳能学习套件

May 28, 2013 · 这份应用报告早仔细检查了太阳能学习套件硬件并解释了使用此套件的光伏(PV) 逆变器的控制设计。

6 FAQs about [Photovoltaic inverter OCVT]

What is a photovoltaic inverter?

Photovoltaic Silicon crystalline module for fields, Photovoltaic structures industrial/residential and generally for all-purpose use. The photovoltaic inverter is the key device of the photovoltaic system which transforms the power produced by the photovoltaic modules (in DC) into useful power (in AC).

What is a photovoltaic inverter (PVI) station?

It is based on the same best-in-class power conversion platform as our AMPS solutions, enabling greater scalability and flexibility. Hitachi Energy’s Photovoltaic Inverter (PVI) station provides you with advanced control and power capabilities that are designed to meet complex technical requirements and the most challenging grid codes.

Why are PV inverters so popular?

As PV systems need an electronic interface to be connected to the grid or standalone loads, the PV market has started appealing to many power electronics manufacturers. Improvements in design, technology and manufacturing of PV inverters, as well as cost reduction and high efficiency, are always the main objectives, [see References 1, 2].

Is a power converter suitable for photovoltaic applications?

For this reason, the power converter, based on a dual-stage topology, has been investigated and experimentally evaluated for photovoltaic applications. The converter performs MPPT and grid connection by means of an ARM Cortex M3-based STM32F103xx microcontroller, which is proven to be well suited for such an application.

What is the supply voltage of the IC and opto-isolator?

The +15 V supply voltage of the IC and opto-isolator is provided by an isolated DC-DC converter, as shown in Figure 20. A similar solution was used to drive the IGBTs in the inverter bridge.

What are the control issues of a PV converter?

For this application, the three main control issues regarding a PV converter, namely, MPPT, grid synchronization and power management control, have been included within the firmware.

Learn More

- Manama single phase photovoltaic inverter manufacturer

- Agent for home photovoltaic inverter

- Zambia photovoltaic inverter manufacturer

- How many volts does a photovoltaic inverter have

- Photovoltaic inverter specifications

- Photovoltaic panel inverter electric complementarity

- Hundreds of watts of photovoltaic inverter

- How is the photovoltaic power generation of the Tehran communication base station inverter

- Photovoltaic inverter capacitance measurement

Industrial & Commercial Energy Storage Market Growth

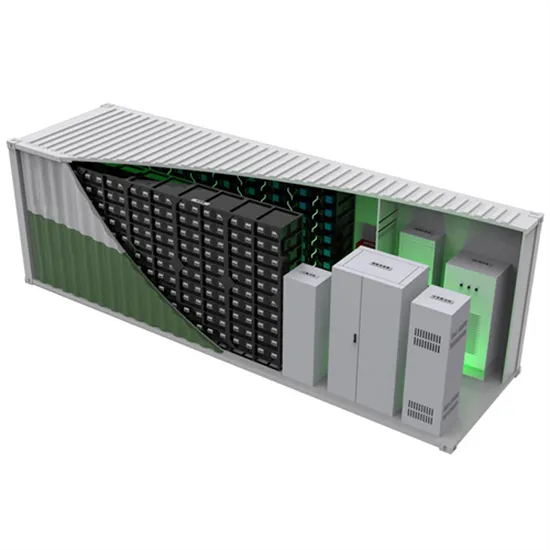

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.