Selection and maintenance of battery for communication base station

Mar 30, 2025 · Abstract: Battery is a basic way of power supply for communications base stations. Focused on the engineering applications of batteries in the communication stations, this paper

Introduction to Communication Base Station Batteries

What is the traditional configuration method of a base station battery? The traditional configuration method of a base station battery comprehensively considers the importance of the 5G base

Installation and commissioning of energy storage for

The communication base station backup power supply has a huge demand for energy storage batteries, which is in line with the characteristics of large-scale use of the battery by the ladder,

EVE 280AH 3.2V Battery in a Communication Base Station

The communication base station is located in a remote area where power outages are common. It needs a backup power system that can provide stable electricity for at least 24 hours during

Battery Management System for Communication Base Stations

Why do communication base stations use battery energy storage? Meanwhile, communication base stations often configure battery energy storage as a backup power source to maintain the

Energy Storage in Telecom Base Stations: Innovations

With the relentless global expansion of 5G networks and the increasing demand for data, communication base stations face unprecedented challenges in ensuring uninterrupted power

Selection and maintenance of batteries for communication base stations

This article focuses on the engineering application of the battery in the power supply system of the communication base station, and focuses on the selection, installation and maintenance of the

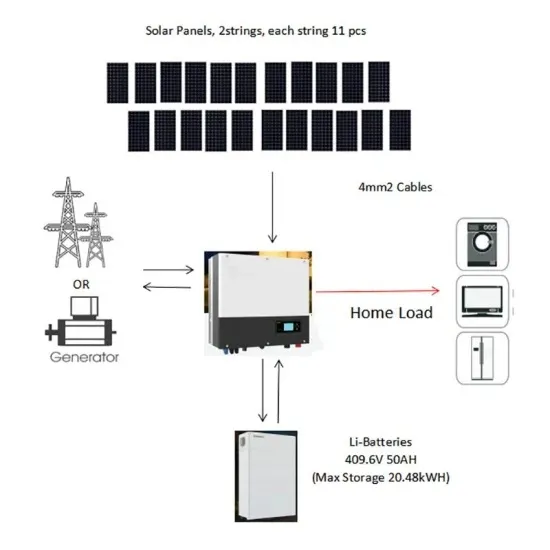

Telecom Base Station PV Power Generation System

Feb 1, 2024 · The communication base station installs solar panels outdoors, and adds MPPT solar controllers and other equipment in the computer room. The power generated by solar

Environmental feasibility of secondary use of electric vehicle

May 1, 2020 · The choice of allocation methods has significant influence on the results. Repurposing spent batteries in communication base stations (CBSs) is a promising option to

Communication Base Station Lithium Battery Solutions

Why Are Traditional Batteries Failing Our 5G Future? As global 5G deployments surge 38% year-over-year (Omdia, Q2 2023), communication base station lithium battery solutions face

Base Station (Gen 3) Installation Guide | SimpliSafe Support

NiMH Rechargeable Batteries Only use NiMH Rechargeable Batteries - never insert regular, alkaline batteries into your Base Station! Watch this video from our team of experts for a hands

Battery technology for communication base stations

In order to ensure the reliability of communication, 5G base stations are usually equipped with lithium iron phosphate cascade batteries with high energy density and high charge and

Selection and maintenance of battery for communication base station

Mar 30, 2025 · Focused on the engineering applications of batteries in the communication stations, this paper introduces the selections, installations and maintenances of batteries for

Lithium-ion Battery For Communication Energy Storage System

Aug 11, 2023 · If so, let''s get to know the right LiFePO4 manufacturers? Specialist Suppliers - We keep comprehensive stocks across the range and and offer excellent technical back-up,

6 FAQs about [Battery installation process for communication base station]

What makes a telecom battery pack compatible with a base station?

Compatibility and Installation Voltage Compatibility: 48V is the standard voltage for telecom base stations, so the battery pack’s output voltage must align with base station equipment requirements. Modular Design: A modular structure simplifies installation, maintenance, and scalability.

How do you protect a telecom base station?

Backup power systems in telecom base stations often operate for extended periods, making thermal management critical. Key suggestions include: Cooling System: Install fans or heat sinks inside the battery pack to ensure efficient heat dissipation.

Which battery is best for telecom base station backup power?

Among various battery technologies, Lithium Iron Phosphate (LiFePO4) batteries stand out as the ideal choice for telecom base station backup power due to their high safety, long lifespan, and excellent thermal stability.

What is a battery management system (BMS)?

Battery Management System (BMS) The Battery Management System (BMS) is the core component of a LiFePO4 battery pack, responsible for monitoring and protecting the battery’s operational status. A well-designed BMS should include: Voltage Monitoring: Real-time monitoring of each cell’s voltage to prevent overcharging or over-discharging.

Why is backup power important in a 5G base station?

With the rapid expansion of 5G networks and the continuous upgrade of global communication infrastructure, the reliability and stability of telecom base stations have become critical. As the core nodes of communication networks, the performance of a base station’s backup power system directly impacts network continuity and service quality.

What makes a good battery management system?

A well-designed BMS should include: Voltage Monitoring: Real-time monitoring of each cell’s voltage to prevent overcharging or over-discharging. Temperature Management: Built-in temperature sensors to monitor the battery pack’s temperature, preventing overheating or operation in extreme cold.

Learn More

- Battery installation container for communication base station

- Battery installation for communication base station

- Montevideo communication base station battery energy storage system construction process

- The process of the communication base station battery energy storage system is

- Base station communication equipment power supply installation

- Reykjavik communication base station wind and solar hybrid power generation installation

- Havana Communication Base Station Lithium Ion Battery Equipment Company

- Communication base station inverter grid-connected indoor battery

- Communication base station battery R

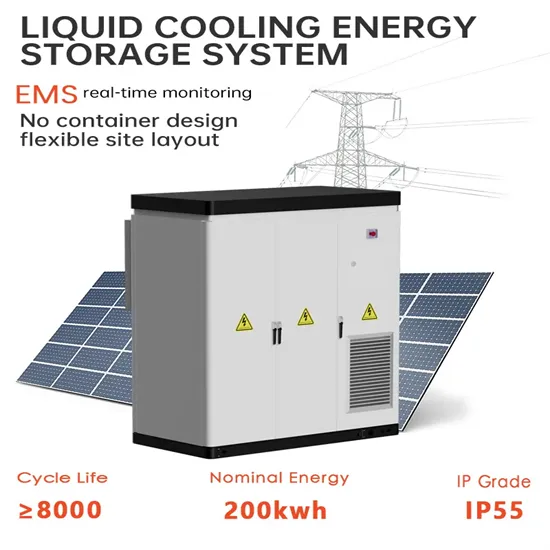

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.