What is the difference between a double-sided double-glass

May 22, 2025 · The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

Insulated Glass Unit | Saint-Gobain Glass India

2 days ago · Insulated Glass combines two or more glass panes that are spaced apart and sealed with a sealant to appear as a single unit. Also called double glazing, IGUs are designed to

PPG Intercept¬ Insulating Glass

Oct 10, 2019 · In laminated IGU glass construction, the low-E coated surface location will have a significant impact on both performance and aesthetics, and should be appropriately

The Tectonics of the Double Skin: Valid Energy Efficient

The heated "used" air between the glazing layers is extracted through the cavity with the use of fans and thereby tempers the inner layer of glazing while the outer layer of insulating glass

Double Glazed Window Parts Diagram and Components

Understanding the parts of a double glazed window can simplify both installation and maintenance. A clear visual representation helps to identify each component''s role in ensuring

The Difference Between Double-glass and Single

Aug 17, 2023 · The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design, which

Glass specification explained: double, triple and laminated

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Guide to Double Glazed Units | Prentice Glass

3 days ago · To kick things off, let''s start by demystifying what double glazed units are. These units, often referred to as double glazing or insulated glass units

Energy-saving performance of respiration-type double-layer glass

Dec 1, 2021 · The development of energy-saving technologies for buildings is an important means of achieving carbon neutrality. The respiration-type double-layer glass curtain wall (RDGCW)

brochure_expert_series_EN_doc3_igu_2020

Feb 16, 2021 · An insulating glass unit (IGU) is a glazing assembly comprised of two or more lites of glass separated by one or more hermetically sealed cavities, filled with either air or inert

DOUBLE LAYER LAMINATED SAFETY GLASS

Apr 28, 2023 · DOUBLE LAYER LAMINATED SAFETY GLASS Designing for Safety The primary goal of safety glazing is to protect people from accidental glass impact, breakage or fallout.

Design Considerations for Laminated Glazing Applications

Nov 18, 2021 · Multiple-Ply Laminates incorporating both glass and polycarbonate components and their appropriate interlayer(s) are further described within ASTM C1349 Standard

Technical Information

Sep 14, 2020 · maximum glass sizes are dictated by the size of glass available from the primary manufacturer, the fabrication equipment limitations, the capabilities of the contract glazier to

FB66-20 Introduction to Vacuum Insulating Glazing

Aug 6, 2021 · Introduction to Vacuum Insulating Glazing Vacuum Insulating Glass (VIG) provides similar or superior thermal performance to conventional double glazing in the thickness of a

6 FAQs about [Glass layer specifications of double-glass components]

What are double glazed units?

To kick things off, let’s start by demystifying what double glazed units are. These units, often referred to as double glazing or insulated glass units (IGUs), consist of two glass panes separated by a spacer, typically filled with argon or krypton gas. We’ll delve into how these components work together to provide an array of benefits.

What are the parts of a double glazed window?

Understanding the parts of a double glazed window can simplify both installation and maintenance. A clear visual representation helps to identify each component’s role in ensuring insulation and energy efficiency. The window typically consists of two panes of glass, separated by a spacer bar that creates an insulating air gap.

What is a double glazed window (DGU)?

Each DGU has two sheets of glass sealed together, separated by a spacer bar. Compared to single layer, float glass, DGUs offer increased solar, thermal and acoustic efficiency across a range of residential and commercial applications, and environments. DGUs are the glass component of double glazed windows and doors.

What is a double glazed Unit (DGU)?

TuffCo manufacture custom Double Glazed Units (DGUs) using computer automated DGU line technology. Each DGU has two sheets of glass sealed together, separated by a spacer bar.

What are double glazed windows & doors?

DGUs are the glass component of double glazed windows and doors. We can manufacture custom DGUs to your specifications using float or laminate glass from our line of stocked glasses, including float and laminate glasses, and performance float and performance laminate glasses designed for Australian conditions.

What are the benefits of double glazed units?

Energy Efficiency: The role of double glazed units in reducing energy consumption and lowering heating and cooling costs. Noise Reduction: How the dual panes of glass and gas fillings create a barrier against external noise, providing a quieter indoor environment.

Learn More

- Color PVB high efficiency double glass components

- Which manufacturer has Panama double glass components

- Make double glass components

- Install double glass components

- Non-monocrystalline double-glass components

- Praia New Energy BIPV Photovoltaic Glass Components

- Specifications of photovoltaic glass

- Double glass components are lightweight

- Photovoltaic glass greenhouse specifications

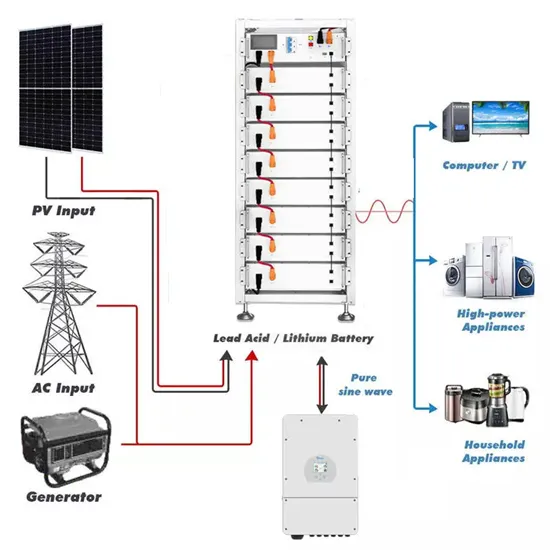

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

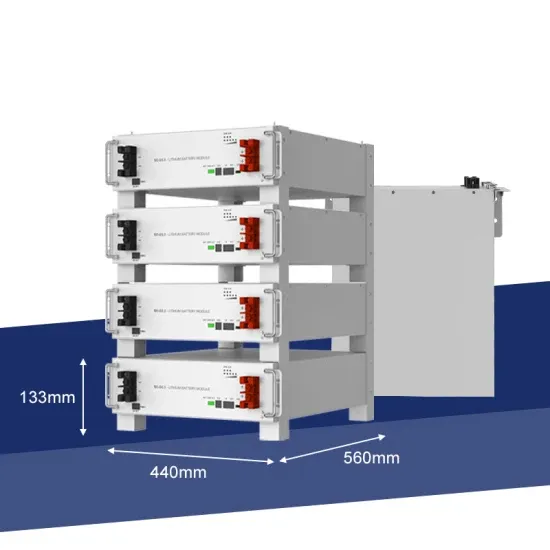

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.