PUH 12V 3000W Pure Sine Wave Inverter with UPS Transfer

The Renogy 3000W Pure Sine Wave Power Inverter is the perfect accessory for smaller off-grid systems, serving as a DC to AC converter, transforming battery-stored DC power into AC

Calculate Battery Size For Any Size Inverter

Mar 3, 2023 · To calculate the battery capacity for your inverter use this formula. Inverter capacity (W)*Runtime (hrs)/solar system voltage = Battery Size*1.15.

Pure Sine Wave Inverter 12V 3000W IPower-Plus Series Kit

IPower-Plus is a high-frequency pure sine wave inverter that can convert 12VDC to 220/230V AC. It is designed according to the international standard with higher quality, reliability, and safety.

3000W Inverter: What Can a 3000W Inverter

Jun 11, 2025 · A 3000W inverter converts power from solar panels, batteries, and other sources into usable AC electricity for homes and businesses. This article

3000W Solar Inverter Guide 2025: Reviews, Installation & Sizing

Jul 17, 2025 · Complete guide to 3000W solar inverters. Compare top models, learn installation basics, and find the perfect inverter for your off-grid system. Expert tested reviews included.

PowerDrive Plus 3000 Watt Power Inverter with Bluetooth(R)

This PowerDrive Plus Bluetooth (R) inverter offers advanced wireless remote-control compatible with all Android (R) and iOS smartphones. The free PowerDrive Plus phone app lets you

Number of Batteries Required for a 3000-watt

Jan 9, 2025 · Today, we will discuss the batteries required for a 3000w inverter and explain how long it takes to operate your devices. The number of batteries

3000W DC 24V Pure Sine Wave Inverter with 80A MPPT

About this item 【All-in-one solar charge inverter】: SUNGOLDPOWER 3000W DC 24V Solar Inverter Charger Combined with 80A MPPT solar Charging and 40A AC battery charging,you

Configure Batteries for 3000W Inverter Power

Jun 19, 2024 · Configuring batteries for a 3000W inverter involves understanding power requirements, calculating necessary capacity, and selecting appropriate

What 3000W inverter to pick.

Jan 16, 2025 · 600ah will work. 300ah would have to pull 1c and have a monster BMS (if it''s a single battery) to power a 3000w inverter at max current (275-325a). Why do you need 3000w?

Calculating the Right Battery Size for Your 3000W Inverter: A

Calculating the right battery size for a 3000W inverter involves understanding your power requirements, determining the appropriate battery capacity, considering inverter efficiency, and

60v45a电池加装3000w逆变器 -SolarEnergyPro

The REGO 12V 3000W inverter charger combines the inverter and battery charger into one complete powerful solution. 3000W continuous pure sine wave AC output and peak power up

Calculating the Right Battery Size for Your 3000W Inverter: A

When it comes to setting up an off-grid power system or a backup power solution, one of the most critical components to consider is the battery bank. The size and capacity of your battery bank

PowMr 3000W Solar Inverter, 24V DC to 120V AC with 80A

PowMr 3000W Solar Inverter, 24V DC to 120V AC with 80A MPPT Controller and 40A AC Charger Built-in, Pure Sine Wave Power Inverter 3000Watt, Max.PV Input 450V, Fit for Lithium

What Size Battery Do You Need to Run a 3000

Mar 16, 2024 · To determine the battery size needed to run a 3000 watt inverter, you need to consider three key factors: the inverter''s continuous power output,

VOLTWORKS 3000W Pure Sine Wave Power Inverter 3000

Jul 26, 2019 · The LCD display shows the batteries status, output voltage, input voltage and some protection codes when inverter is in protection mode. 【Advance Protection】ETL listed 3000W pure sine wave inverter including Short circuit protection, Input over-voltage/ under-voltage

6 FAQs about [60v45a battery plus 3000w inverter]

Can you run a 3000 watt inverter on one battery?

You need 4 Lithium batteries in series to run a 3,000W inverter. If you use lead-acid batteries, you need 12 batteries with 4 in series and 3 strings in parallel. Can I run a 3000 watt inverter on one battery? You can but it’s not recommended because you will reduce the battery lifespan, or the BMS will stop the discharge.

How many amps does a 3000 watt inverter use?

Since the recommended C-Rate for lithium batteries is 0.5C, you would need at least batteries with a capacity of (250A ÷ 0.5 =) 500Ah 12V or 6 kWh. For a 3000 watt inverter at 24 volts: 3000 watts / 24 volts = 125 amps. You would need batteries with a capacity that allows the inverter to draw 125 amps safely.

How many amps does a 12V 3000 watt inverter draw?

For a 12V 3000 watt inverter: 3000 watts / 12 volts = 250 amps. This means that when fully loaded (3000 watts), it will draw 250 amps from the batteries (ignoring things like efficiency). So, you would need batteries with a capacity to meet a discharge rate (C-Rate) that allows the inverter to draw 250 amps safely.

How many batteries do you need for a 3,000w inverter?

If we put 4 batteries in series we have one 48V 100Ah battery. The c-rate of lead-acid is 0.2C. We can draw 100Ah x 0.2C = 20Amps. That’s not enough to power the 3,000W inverter. We saw previously that we need 62,5A if we have a 48V system. That means we need three parallel strings of 4 batteries in series for a total 12 batteries.

How do I choose the right battery for my 3000W inverter?

Choosing the right type of battery for your 3000W inverter depends on several factors, including the size of your system, the type of appliances you plan to run, and your budget. There are several types of batteries available, including lead-acid, AGM, and lithium-ion batteries.

How long can a 3000 watt inverter run?

Let’s say you have a 300Ah battery. 300 ÷ 250 = 1.2 hours. Drawing 3000 watts from a 300Ah battery will run for a maximum of 1.2 hours. If you reduce your power draw to 2000 watts, you would increase your runtime to nearly 2 hours! Remember, a 3000W inverter won’t always draw maximum power, it depends what appliances you are running.

Learn More

Industrial & Commercial Energy Storage Market Growth

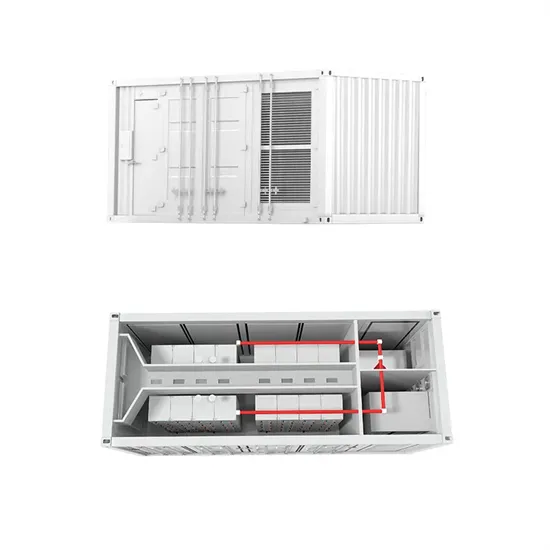

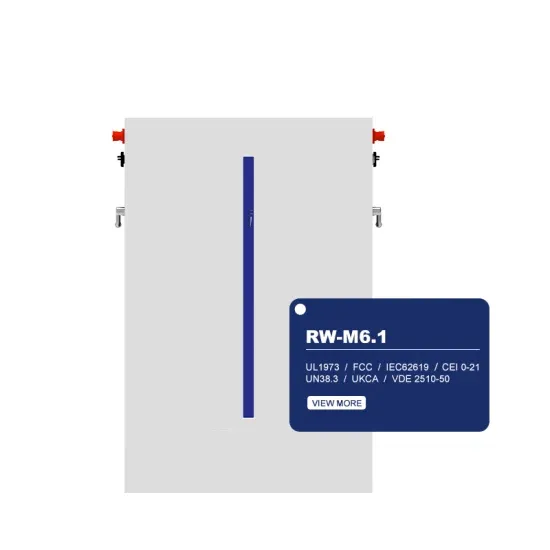

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.