Stochastic optimisation and economic analysis of combined high

Jul 1, 2023 · High Temperature Superconducting (HTS) Magnetic Energy Storage (SMES) devices are promising high-power storage devices, although their widespread use is limited by

The Application in Spacecraft of High Temperature

Nov 2, 2023 · Abstract| This paper has analyzed the requirement of energy storage devices in spacecraft and introduced the present development situation of high temperature

Application of YBCO high temperature superconducting

Aug 18, 2025 · In this paper, based on the introduction of YBCO high temperature superconducting tape, the performance requirements of energy storage devices is analyzed,

High Temperature Superconductor-Based Technologies as

Apr 9, 2019 · New technologies based on the use of High Temperature Superconductors (HTS) can lead to higher efficiency and more resilient energy systems. HTS applications are creating

Application of YBCO high temperature superconducting

Jul 3, 2024 · Due to the superior current-carrying capacity, high operating temperature, and relatively low fabrication cost of second-generation high-temperature superconducting tapes,

High-temperature Superconductors: Paving the Way for

May 14, 2024 · Superconducting power cables made from HTS materials can carry electricity with minimal losses, reducing transmission inefficiencies and lowering energy costs. Additionally,

Design and development of high temperature superconducting

Aug 15, 2019 · In addition, to utilize the SC coil as energy storage device, power electronics converters and controllers are required. In this paper, an effort is given to review the

Overall design of a 5 MW/10 MJ hybrid high-temperature superconducting

Dec 29, 2023 · Superconducting magnetic energy storage (SMES) uses superconducting coils to store electromagnetic energy. It has the advantages of fast response, flexible adjustment of

Superconducting Magnetic Energy Storage (SMES) Systems

Jul 16, 2015 · Superconducting magnetic energy storage (SMES) systems can store energy in a magnetic field created by a continuous current flowing through a superconducting magnet.

The Interaction Between a High-Temperature Superconducting

Jan 22, 2024 · Due to excellent properties of large current-carrying capability and high critical magnetic field, high-temperature superconducting (HTS) materials play an increasingly

Application of YBCO high temperature superconducting

Due to the superior current-carrying capacity, high operating temperature, and relatively low fabrication cost of second-generation high-temperature superconducting tapes, they are widely

Design, dynamic simulation and construction of a hybrid HTS SMES (high

Mar 1, 2013 · High-temperature superconducting magnetic energy storage systems (HTS SMES) are an emerging technology with fast response and large power capacities which can address

High-temperature superconducting energy storage

Sep 29, 2024 · High-temperature superconducting energy storage technology, with its high efficiency and fast energy storage characteristics, exhibits great application potential in

Construction Begins on World''s Largest High-Temperature Superconducting

May 25, 2025 · The construction of the world''s largest high-capacity high-temperature superconducting magnetic energy storage (SMES) device has officially begun in the Cuixiang

High-Temperature Superconductivity: A Roadmap for

Feb 20, 2017 · The document highlights trends and drivers in the electric power industry that could potentially enable HTS devices to be energized in the grid. Challenges and needs are

Theoretical calculation and analysis of electromagnetic

Nov 15, 2024 · This article presents a high-temperature superconducting flywheel energy storage system with zero-flux coils. This system features a straightforward structure, substantial

Experimental demonstration and application planning of high temperature

Jan 1, 2015 · Since high temperature superconducting magnetic energy storage system (HT SMES) has attracted significant attention for their fast response in milliseconds, high efficiency

6 FAQs about [High-temperature superconducting energy storage device]

What are high-temperature superconductors used for?

High-temperature superconductors are now used mostly in large-scale applications, such as magnets and scientific apparatus. Overcoming barriers such as alternating current losses, or high manufacturing costs, will enable many more applications such as motors, generators and fusion reactors.

What is superconducting magnetic-energy storage (SMES)?

Unlike conventional batteries, which use chemicals to store energy, superconducting magnetic-energy storage (SMES) uses a magnetic field created by the flow of direct current in a coil of superconducting material. Once the coil is charged, the energy can be stored nearly indefinitely with little to no decay, provided that the cooling is maintained.

Can high-temperature superconductors be used in large-scale applications?

Developments in HTS manufacture have the potential to overcome these barriers. In this Review, we set out the problems, describe the potential of the technology and offer (some) solutions. High-temperature superconductors are now used mostly in large-scale applications, such as magnets and scientific apparatus.

What is high-temperature superconductivity?

But the 1986 discovery of high-temperature superconductivity paved the way for broader applications. “High temperature” isn’t room temperature. It refers to materials that superconduct above −195.79 °C, the boiling point of liquid nitrogen.

Which energy storage system is most efficient?

Though, SMES is the most efficient ESS with a fast response quality, its cost increases with its energy storage capacity. The hybrid energy storage technology is mainly planned to reduce the cost of SMES by diverting the job to other ESS where slow and long time response is required.

What is a medium temperature superconductor (MTS)?

As the critical temperature of MgB 2 is 20 K (in between HTS, 77–90 K and LTS, 4.2 K) it can be treated as Medium Temperature Superconductor (MTS). After selecting the HTS tape, the arrangement of coil should be selected depending on the rating of the proposed SMES. The most common arrangements of superconducting coil are solenoid and toroid.

Learn More

- Energy storage device for valley power and peak power

- Energy storage cabinet anti-backflow device base station

- A MW energy storage device occupies an area

- German energy storage inverter device

- Which large energy storage device is the cheapest

- Power assist device and energy storage device

- Bloemfontein lithium iron phosphate portable energy storage device

- Madagascar Valley Electric Energy Storage Device Manufacturer

- Guyana Phase Change Energy Storage Device

Industrial & Commercial Energy Storage Market Growth

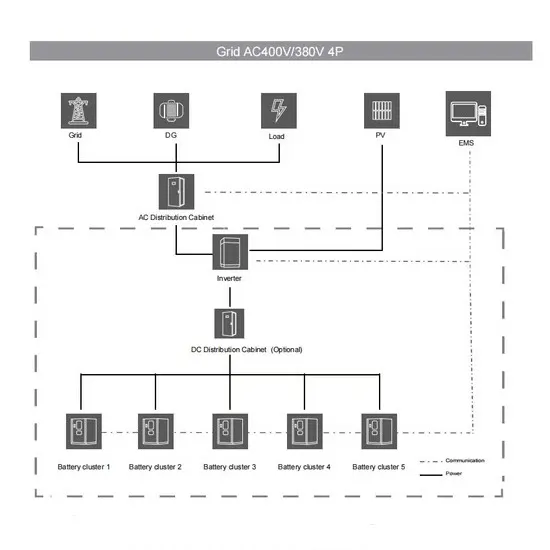

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.