Battery cabinets | Legrand Data Center Solutions

Jun 19, 2025 · The battery cabinets are available in five different mechanical dimensions. They can facilitate multiple combinations of batteries, up to 63 battery blocks, connected in series

INDOOR ALARMED DEFIBRILLATOR CABINET BATTERY

Sep 18, 2022 · . ocate the black battery pack inside the AED Alarmed Cab ne p ld ng 5. Slide down the battery pack into the holder. 6. Please make sure to turn ON the alarm switch. 03

PDU8000 Battery Cabinet-T Quick Guide (02405680)

Nov 1, 2019 · 安装过程中,产品出厂原配部件不能擅自更换,如需更换,请联系华为工程师。 1. Move the cabinet from the wood pallet to the ground. 将机柜从木栈板移动至地面。 1.1 Safety

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the

PDU8000 电池柜-T 快速指南 (02405362)

Jun 18, 2019 · 安装过程中,产品出厂原配部件不能擅自更换,如需更换,请联系华为工程师。 1. Move the cabinet from the wood pallet to the ground. 将机柜从木栈板移动至地面。 1.1 Safety

UPS Battery Cabinet Upgrade, Retrofit, Replacement

5 days ago · Whether leveraging an existing cabinet through a like-for-like replacement or opting for a new UPS battery cabinet or rack altogether, you''ll need to consider connector

Installation and Maintenance Manual

Jan 31, 2024 · When there are more than two battery cabinets, it is recommended to provide a battery switchboard. DANGER Different connection solutions are the sole responsibility of the

Practical guide to electric motorcycle swappable

6 days ago · With the battery swapping system, motorcycle riders can remove the drained battery from the electric motorcycle, put it into the battery swapping

UNDERSTANDING UPS SYSTEMS AND BATTERIES

Jul 17, 2024 · Battery types Batteries are available in a range of technologies, including lead-acid, nickel- cadmium, lithium ion, lithium-sulfur, aluminum-ion, nickel-metal, and more. Of all these,

UBC80 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Connects the battery cabinet to the UPS Automatically locks the battery cabinet door to prevent access to the cabinet interior during its operation as a power backup to the UPS.

PDU8000 电池柜-T 快速指南 (02405362)

Jun 18, 2019 · 本文档主要介绍电池柜安装和调试的操作方法。2 Tools / 安装工具 4 Installing a Battery Cabinet / 安装电池柜 PDU8000 Battery Cabinet-T Quick Guide 4.1 Checking Before

Battery Swap Cabinet FAQ

Jul 21, 2025 · The battery swap cabinet is composed of a cabinet body and a battery pack, including functional units such as a power supply system, a control system, a charging system,

Smart Battery Swapping Cabinets for Electric Motorcycle Fleets

May 8, 2012 · As a leading battery swapping cabinet manufacturer, Atom Moto specializes in OEM/ODM battery swap cabinets designed for seamless electric vehicle battery exchanges.

Replace or Install a Modular Battery String

Connect the battery terminals to the front of the battery module. See View the Modular Battery Status to verify correct installation of the battery modules. Reinstall the battery cover on the

BC58 Battery Cabinet Installation, Operation,

Isolates the battery cabinet from the UPS Divides the 540VDC battery string into two (2) battery strings of 270VDC each. Unlocks the battery cabinet doors to allow access to the cabinet

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Battery Cabinet

Feb 28, 2025 · If replacement of a battery is necessary in a string that is more than 4 – 5 years old, replace the entire string. Defective batteries in a string that is less than 6 months or 1 -2

Replace or Install a Modular Battery String

Set the battery disconnect device BB to the open (OFF) position on the UPS and/or the modular battery cabinet where battery modules must be replaced or installed. Remove the battery

310484 Modular Battery Cabinet Keor Mod

Jun 23, 2023 · The battery cabinet should be installed in a room with adequate air ventilation flow to avoid dangerous concentration of hydrogen gas that can be produced during battery recharge.

BATTERY CABINET FOR 3PH UPS 310620-310621-310622

Jun 14, 2021 · The Battery cabinet family is designed to house standard VRLA Batteries of capacity range from 24Ah to 105Ah (C10). The battery cabinets, with 5 different mechanical

Eaton 9355 (20/30 kVA) UPS battery upgrade instructions

Sep 9, 2024 · The total battery string voltage in a 9355 20-30 kVA UPS is 216V (18 batteries, where is each battery is 12V nominal). Two strings fit in each battery shelf of the 9355 20-30

BC55 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Isolates the battery cabinet from the UPS Divides the 480VDC battery string into two (2) battery strings of 240VDC each. Unlocks the battery cabinet doors to allow access to

Battery Swap Cabinets Spots: A Guide to Efficient Battery Replacement

Jan 15, 2024 · Battery swap cabinets offer a practical solution for efficient battery replacement in the electrical and electronic equipment manufacturing industry. These cabinets improve

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Securing the battery storage cabinet involves using appropriate methods and materials to ensure stability and safety. Begin by selecting the correct fasteners for your wall or

Powerware 9395 Integrated Battery Cabinet (Model IBC

Jun 17, 2016 · 1 Introduction During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load.

6 FAQs about [Replace the battery cabinet]

How do I install a battery cabinet?

Create an installation plan for the battery cabinet (Chapter 2). Prepare your site for the battery cabinet (Chapter 2). Inspect and unpack the battery cabinet (Chapter 2). Unload and install the battery cabinet, and wire the system (Chapter 3). Complete the Installation Checklist (Chapter 3).

How do I install a battery cabinet breaker?

Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the matching connector in that cabinet (see Drawing 164201536-8 on page A-17). If installing multiple battery cabinets, proceed to Step 3; otherwise, proceed to Step 5.

How do I connect a ups to a battery cabinet?

Locate the UPS-to-battery cabinet breaker sensing cable inside the first battery cabinet. Mate the connector on this cable with the matching connector in the cabinet (see Drawing 164201536-8 on page A-17). Route the other end of this cable through conduit (top or bottom entry) to UPS cabinet and connect to terminal strip TB2.

How do you secure a battery cabinet?

Secure the battery cabinet position by lowering the leveling feet until cabinet is not resting on the casters. Ensure the cabinet is level and matches the height of the installed UPS cabinet. NOTE Two cabinet joining brackets are provided in the field kit for securing each cabinet at the top and bottom.

Where is the UPS battery cabinet located?

The battery cabinet may be located to either the left or right of the UPS cabinet. The recommended location is to the left of the UPS cabinet. This procedure assumes the battery cabinet is located to the left of the UPS cabinet. Figure 3‐2. UPS with Line-up-and-Match IBC-S

What is a battery cabinet?

The battery cabinet is designed for industrial or computer room applications and should be handled with appropriate care. This battery cabinet contains LETHAL VOLTAGES. All repairs and service should be performed by AUTHORIZED SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE PARTS

Learn More

- Replace the battery cabinet

- How much does it cost to replace a battery cabinet in Luanda

- Replace new energy battery cabinet

- How much does it cost to replace a battery cabinet in Portugal

- Manila energy storage cabinet battery structure

- Battery cabinet battery soh

- Battery cabinet components

- Battery cabinet label meaning

- 40 kWh lithium iron phosphate battery station cabinet

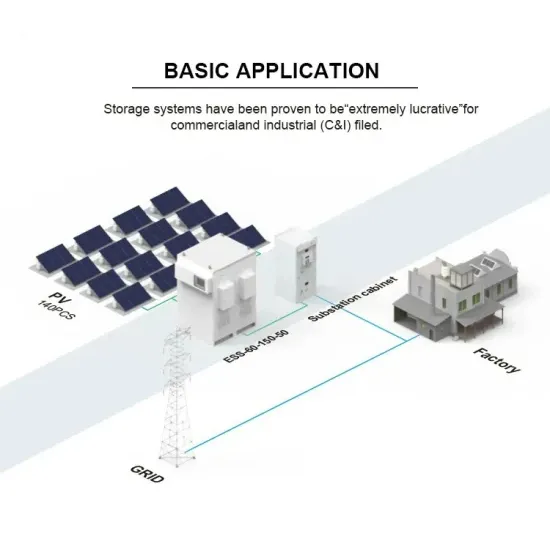

Industrial & Commercial Energy Storage Market Growth

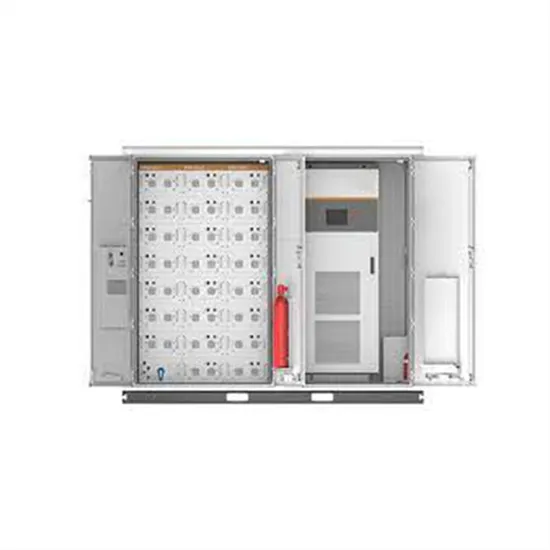

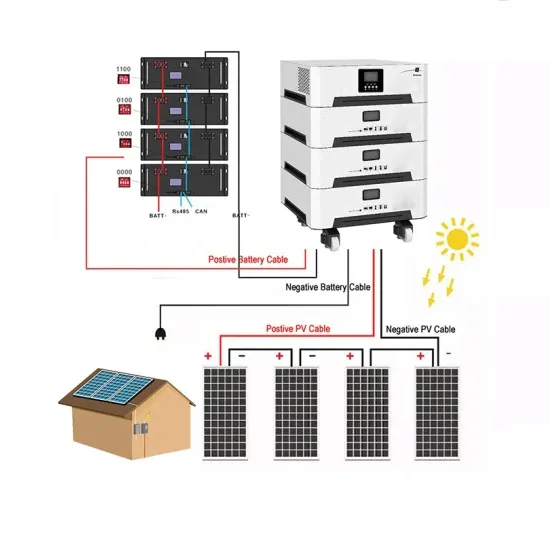

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.