High-voltage energy storage power station module

Due to the dual characteristics of source and load, the energy storage is often used as a flexible and controllable resource, which is widely used in power system frequency regulation, peak

Function of high voltage energy storage module

A high-voltage energy storage system (ESS) offers a short-term alternative to grid power,enabling consumers to avoid expensive peak power charges or supplement inadequate grid power

Energy storage systems design resources | TI

3 days ago · Learn about the innovations that make it possible to use Hall-effect current sensors in high-voltage applications such as solar and electric vehicle charging to simplify current

CHN Energy''s Largest Electrochemical Energy Storage Power Station

May 27, 2025 · On May 15, the Hainan Talatan 255 MW × 4h energy storage project, developed by China Energy Investment Corporation Co., Ltd. (CHN Energy)''s Qinghai Gonghe Company,

High-Voltage SiC Power Modules for 10 – 25 kV

Apr 20, 2016 · The two SiC power modules described in this article clearly demonstrate the potential for SiC devices in high-voltage applications, including energy storage, grid-connected

NR Leads In High Voltage Energy Storage Technology

Mar 12, 2025 · NR has provided a complete set of solutions for Shaoxing 35kV high voltage direct coupled energy storage system, including energy management system (EMS), Power

Stackable High Voltage Energy Storage System | IMPROVE

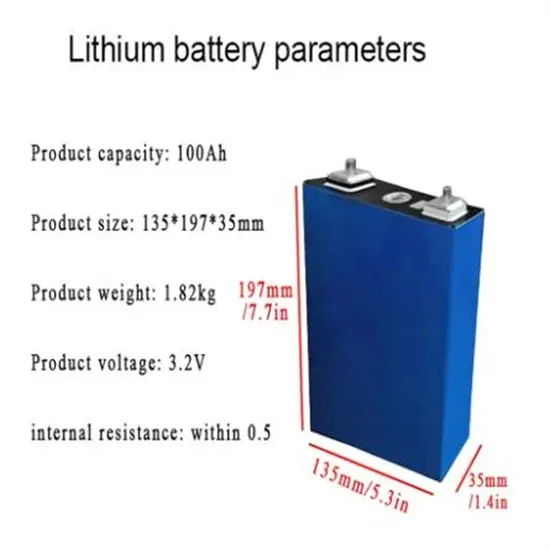

Jul 20, 2025 · IMP 100Ah Hig Voltage Energy Storage Series are designed with a modular approach, allowing for easy expansion or reduction of storage capacity by adding or removing

High-voltage energy storage power station module

power station module Introduction For new installations of household energy storage, Redway Power''''s Rack LiFePO4 Battery Module (Stack Rack Battery, Energy Storage System Battery)

High-Voltage SiC Power Modules Advance Renewable Energy Storage S

This blog examines how silicon carbide (SiC) power modules advance BESS, focusing on their efficiency, scalability, and system reliability features, and considers versatile power modules

6 FAQs about [High-voltage energy storage power station module]

What is a high-voltage energy storage system?

A high-voltage energy storage system (ESS) offers a short-term alternative to grid power, enabling consumers to avoid expensive peak power charges or supplement inadequate grid power during high-demand periods. These systems address the increasing gap between energy availability and demand due to the expansion of wind and solar energy generation.

What types of energy storage systems can ti support?

With advanced battery-management, isolation, current-sensing and high-voltage power-conversion technologies, we support designs ranging from residential, commercial and industrial systems to grid-scale systems with voltages as high as 1,500V. Why choose TI for your energy storage system designs?

What is a high-performance battery management system (BMS)?

These systems address the increasing gap between energy availability and demand due to the expansion of wind and solar energy generation. MPS’s high-performance battery management systems (BMS) carefully manage all of the battery cells within a high-voltage ESS to provide safe and reliable operation with high capacity across a long operating life.

What is high-voltage power-conversion technology?

Our high-voltage power-conversion technology includes: Isolated gate drivers and bias supplies that enable the adoption of silicon carbide field-effect transistors for high-power systems. Gallium nitride devices that lower conduction and switching losses, helping energy storage systems achieve higher power density.

What is a stackable battery management unit reference design?

The stackable battery management unit reference design is a full cell-temperature sensing, high cell voltage accuracy, lithium-ion or lithium-ion-phosphate 32 cells in series battery pack reference design.

What is a high-voltage ESS?

Most high-voltage ESS consist of multiple battery modules (BMUs) to manage and scale a system for site-specific requirements. Within a BMU, MPS’s battery monitoring and protection devices can be used as a comprehensive analog front-end (AFE) to accurately measure up to 16 series Li-ion battery cells.

Learn More

- Energy storage power station charging module

- Energy Storage Container Power Station Service

- Photovoltaic power station energy storage battery brand

- Photovoltaic energy storage power station new energy vehicle

- Alofi Energy Storage Power Station connected to the grid

- San Jose s first grid-connected energy storage power station is put into operation

- Liquid Cooling Container Energy Storage System ESS Power Base Station

- Investment value of New Zealand energy storage power station

- Moscow 7 billion energy storage power station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.