12v Parallel vs 24v Series "Capacity" | DIY Solar Power Forum

Oct 5, 2020 · Say I start out powering my appliances with one 12v 100ah battery, and later down the line I want to switch to a 24v system and purchase a second 12v 100ah battery and wire

Running Inverters in Parallel: A Comprehensive

Jul 14, 2023 · Additionally, running inverters in parallel can improve system reliability and redundancy. If one inverter fails, the others can continue to

Mixing 12v in Series and 24v

Dec 1, 2024 · I will then parallel the sets together so I would have series-parallel set up with 24v coming into the inverter. My original plan was to add two more SOK 12v 206ah batteries to the

Solar Panel Connections: Series vs. Parallel

Oct 5, 2024 · When your inverter or UPS is 12V, you''ll need to connect all your solar panels (those designed for 12V) in parallel. In a parallel connection, the voltage remains the same

Series vs Parallel Battery Wiring: Key Differences,

Apr 8, 2025 · For example: Two 12V 100Ah batteries in series → Output: 24V 100Ah Three 12V 100Ah batteries in series → Output: 36V 100Ah Advantages

12V Inverter vs 24V Inverter — What Is The Difference

Choosing between a 12V and 24V inverter impacts efficiency, performance, and device compatibility. This article will explore the differences between 12v inverter vs 24v inverter,

Charging 12V Batteries: How to Connect and Charge in Series vs Parallel

Aug 6, 2025 · Learn expert methods for charging 12V batteries in series vs parallel. Avoid damage, choose the right charger, and extend battery life with proven tips.

How to Wire Solar Panels in Series-Parallel

Dec 29, 2024 · In this tutorial, we will explain the basic wiring of photovoltaic panels in a series-parallel configuration. This includes connecting them to one

Understanding the Compatibility of 12V Solar Panels with 24V

Apr 7, 2025 · There are two primary ways to integrate 12V solar panels into a 24V system: One effective way to use 12V panels in a 24V solar array is through a series connection. By

12v Inverter on 24v System (12v batteries in series)

I have 6 220w panels going in to a charge controller with 2 12v batteries in series. I prefer to keep the batteries in series because my charge controller will only handle the full wattage of the

What Is the Difference Between Series and Parallel Inverter

Dec 14, 2023 · In a series inverter connection, multiple inverters are connected end-to-end. This configuration increases the total output voltage while keeping the current constant. For

Understanding the Difference Between Series and Parallel

Mar 18, 2025 · Understanding series and parallel battery connections is essential for setting up a reliable 12V power system. Series connections increase voltage while keeping capacity the

Batteries in Series vs Parallel: A Detailed Comparison

A series connection is typically used when a higher voltage is required to power a device or system. For example, if you have two 12V 100Ah batteries connected in series, the result is a

How To Wire Batteries In Parallel Or Series? | Redway Tech

Jun 5, 2025 · Wiring batteries in parallel combines capacity (Ah) while maintaining voltage, whereas series connections increase voltage while keeping capacity constant. Use identical

12V vs 24V Inverters Key Differences and Which

Jan 21, 2025 · In this comprehensive guide, we''ll compare 12V vs 24V inverters in terms of their performance, pros and cons, and ideal use cases to help you

12v/24/48v parallel or series? Confused!!

Jan 4, 2017 · My panels.I believe are all going to be 12v or 18v max I think, but if I did them parallel the voltage would stay 12v which wouldn''t charge a 24v system I thought, so it''d have

Mixing 12v in Series and 24v

Dec 1, 2024 · When I add solar I plan on re-wiring and going to 24v DC input to the inverter, I plan on connecting two each of the 12v batteries in series to give me 24v. This will give me two sets

Batteries in Series vs in Parallel: Here''s All You

Aug 9, 2024 · Can you connect eBike batteries in series vs parallel? Yes, you can connect eBike batteries in series to increase the voltage or in parallel to

How to Connect Two or More Batteries in Series and Parallel

Jan 11, 2025 · The series connection of two identical batteries allows to get twice the rated voltage of the individual batteries, keeping the same capacity. Following this example where there are

24v system: series vs. parallel battery options

Jul 13, 2022 · I''m considering buying a 24v all in one inverter (probably Growatt, maybe MPP Solar) for my camper van. I want the equivalent of 400 ah 12v batteries (or 4800 watt hours). I

How to Wire Solar Panel & Batteries in Series for

2 days ago · This setup is needed in case of a 24V inverter system. For this reason, we have to wire the PV panels and 12V batteries in series to obtain

12V vs 24V vs 48V Inverter: How to Choose the Right System

Jun 16, 2025 · Confused about choosing between 12V, 24V, or 48V inverter systems? Discover which voltage is best for RV, solar, and off-grid setups. Learn the pros, cons, efficiency, cable

I have read that putting 2 transformers in

Dec 9, 2021 · I know if batteries are placed in series, the voltage adds up, and if the batteries are in parallel, the Ah capacity adds up. Is there an analogy

How to connect batteries in series or in parallel?

Mar 13, 2019 · Connecting in Series and Parallel Batteries equalized is to connect to the positive at one end of the battery pack, and the negative at the other

12V vs 24V Inverter: What''s The Difference & Which is Better

When choosing an inverter for your solar system, consider 12V for small setups, 24V for medium-sized systems, and 48 voltage inverter for large installations. Higher voltages offer better

6 FAQs about [12V inverter in parallel or 24V in series]

What is the difference between 12V vs 24V inverters?

Efficiency is an important factor when choosing between 12V vs 24V inverters. In general, 24V inverters are more efficient than their 12V counterparts, especially for larger systems. The efficiency difference becomes more noticeable as you increase the power demand of the system.

What is the difference between 12V and parallel solar panels?

For example, connecting two 12V panels in series will yield a total output of 24V (12V + 12V). On the other hand, wiring solar panels in parallel maintains the same voltage while increasing the current. If you connect two 12V panels in parallel, the output will still be 12V, but the overall current capacity will double.

What is the difference between 12V and 24v battery systems?

It depends on your system’s size, the quality of the inverter, and your power needs. In general, 24V inverters are better for larger systems, while 12V inverters work well for smaller setups. When choosing between 12V and 24V battery systems, it’s important to understand their differences. Let’s take a look the table below:

How do I integrate 12V solar panels into a 24v system?

There are two primary ways to integrate 12V solar panels into a 24V system: One effective way to use 12V panels in a 24V solar array is through a series connection. By connecting two 12V panels together in series, you can create a combined voltage output of 24V.

Can a 12V solar panel be connected to a 24v system?

There can be efficiency losses when connecting 12V solar panels to a 24V system, primarily due to the voltage mismatch. When you connect 12V panels in series to achieve 24V, any fluctuations or variations in sunlight may impact the overall performance, leading to potential energy losses.

How to choose a solar inverter voltage?

Use a 12V inverter for small systems, a 24V inverter for medium-sized systems, and a 48V inverter for large systems. Higher voltages give better efficiency and lower installation costs. Picking the right inverter voltage is important for making your solar system work well and saving money. Key Factors to Consider

Learn More

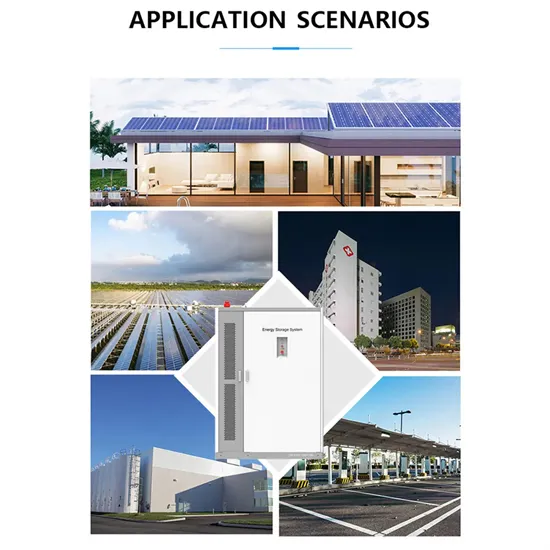

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

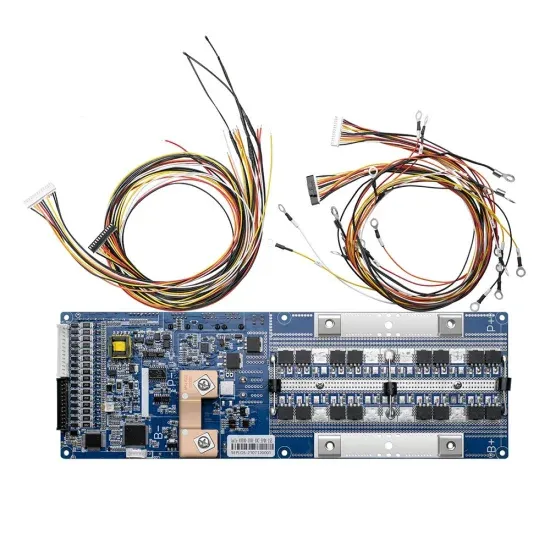

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.