Inverter Types & Working Principle | Sine Wave,

2 days ago · The article provides an overview of inverter technology, explaining how inverters convert DC to AC power and detailing the different types of

pure sine wave inverter manufacturer over 10 years-Junbpaw

4 days ago · 110V 120V Pure Sine Wave Single-phase Inverter Junbpaw design the compact size,lightweight,high effciency pure sine wave inverter over 10 years.With powerful R&D team

Pure Sine Wave Inverter: All You Need to Know

May 10, 2023 · In this blog post, we will explore the fundamentals of pure sine wave inverters, including what they are, how they work, the differences between modified and pure sine wave

Detailed explanation of the production of a 600W sine wave inverter

Dec 26, 2024 · Recently, I spent nearly a month to make a 600W sine wave inverter. The machine has the following features: 1. The SPWM drive core uses a single-chip SPWM chip,

Simple Sinewave Inverter Circuits – Making Easy

Jul 13, 2021 · The following is a high efficiency sine wave inverter electrical diagram, the circuit with 12V battery-powered. First with a double voltage

Paper Title (use style: paper title)

Feb 8, 2016 · The modified sine wave inverter is analyzed by using different PWM generating IC''s like CD4047 and SG3525 and with different designed transformer to reduce the cost and size

DESIGN AND DEVELOPMENT OF SOLAR

Nov 2, 2021 · The simplest way of producing the Sine Pulse Width Modulation signal is through comparing a low power sine wave reference with a high frequency triangular wave, as shown

How To Construct A Pure Sine Wave Inverter Circuit Using Ic

Jul 30, 2016 · The presented circuit produces PWM pulses which are perfectly optimized and is quite similar to a sine wave and thus very much becomes an equivalent to a sine waveform

All rights reserved This work by Wilolud Journals is

Jul 31, 2025 · The electrical circuit of a pure sine wave inverter is far more complex than a square wave or modified sine wave inverter. Another way to obtain a sine output is to obtain a square

i-manager''s Journal on Instrumentation and Control

Square wave, modified square wave and true sine wave inverter circuits with 500W rated power were designed and analyzed using Proteus Professional spice program. This comparison was

An overall introduction of inverter waveform and

Dec 20, 2023 · This article will give you a detailed introduction and comparison of inverter waveform, including the principles of generating different waveforms,

Design your own Sine Wave Inverter Circuit from

Dec 19, 2024 · In this article I have explained comprehensively regarding how to design a sine wave inverter without any form of coding or complex circuit

Pure sine wave inverter manufacturer |Inverter factory |Custom inverter

Jul 24, 2025 · Junbpaw-we are inverter manufacturer over 17 years,focusing on high quality pure sine wave inverter.We support OEM and ODM service.

Design And Construction Of 1KVA Inverter

Inverter Classification Inverters can be classified based on factors such as input voltage, output voltage, power ratings and output waveforms. Square wave inverters are the oldest, simplest

Design of Pure sine wave inverter

May 8, 2024 · Abstract: This paper outlines the design and construction process of a pure sine wave inverter, the inverter are often needed at places where it is not possible to get AC supply

Power Network exclusively reveals the production process of 500W sine

Reference address: Power Network exclusively reveals the production process of 500W sine wave inverter Previous article: Understand the causes and treatment methods of capacitor

From Code to Prototype: How to Design a Low-Cost Pure Sine Wave

Discover how to design a pure sine wave inverter under $100 with this step-by-step guide. Learn from real DIY examples, expert tips, and affordable components like the EGS002 board to

6 FAQs about [Production of the simplest sine wave inverter]

How to design a pure sine wave inverter?

To design a pure sine wave inverter from the scratch, we require the following circuit stages: A basic 50 Hz or 60 Hz inverter circuit. An op amp comparator using IC 741 or by configuring IC 555. Two sets of triangle waveform, one slow (low frequency) and the other fast (high frequency).

What is a sine wave inverter?

A sine wave inverter is a device which converts battery power into a 220 V AC or a 120 V AC sine wave output. There are 3 basic types of inverters: square wave inverter, modified sine wave inverter and a pure sine wave inverter. The voltage waveform output from a square wave inverter is square wave.

How to choose a high efficiency sine wave inverter?

To choose a high efficiency sine wave inverter, first consider the appropriate 12V battery capacity. The following is a high efficiency sine wave inverter electrical diagram, powered by a 12V battery. Begin with a double voltage module for the op amp power supply. The ICL7660 or MAX1044 can be selected for this purpose.

What is a 1kW pure sine wave inverter project?

This project is intended to teach how to desing an inverter from scratch. The project files inculde Read the fabrication report carefully before building the project. The project was funded by IEEE PES with a view to design 1KW Pure Sine Wave Inverter.

Can a sinewave inverter be converted to AC?

A sinewave inverter can be converted to provide AC power for use in the event of a sudden power outage. For instance, in an engine room, a UPS power supply with a sinewave inverter can be used to convert DC power back to AC for a computer, preventing data loss caused by a power outage. This article will introduce two relatively simple sinewave inverter circuit diagrams.

How does a pure sine inverter work?

A pure sine inverter works by inducing an alternating sine waveform pattern across the primary transformer winding with a selected frequency rate. This frequency rate can be 50 Hz or 60 Hz, depending on the country and region specifications. This sine waveform is in the form of sine PWM which is a digital signal and not a linear signal.

Learn More

- High-power sine wave inverter production

- Hanoi Industrial Frequency Pure Sine Wave Inverter

- Sine wave inverter into 60v

- New pure sine wave inverter in Dubai

- Is the sine wave inverter good

- Bern pure sine wave 20kw inverter manufacturer

- Middle East pure sine wave 20kw inverter company

- Inverter and pure sine wave

- Tuvalu sine wave inverter supply

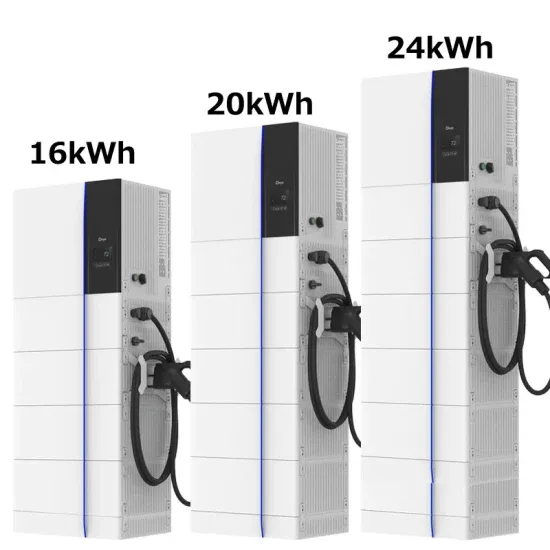

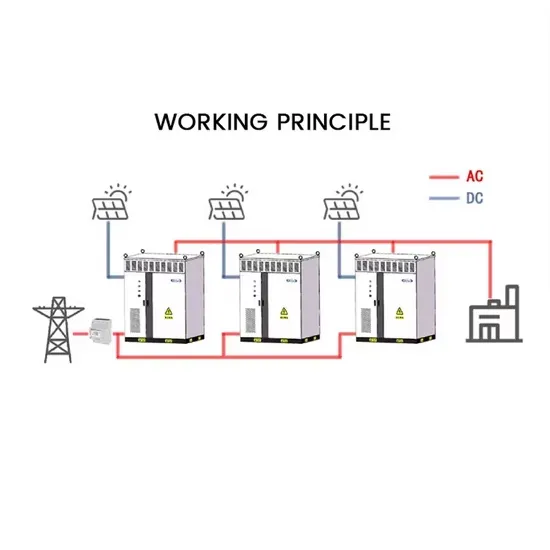

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.