How to Wire Solar Panels to Breaker Box Off

Aug 13, 2023 · This diagram will outline how to connect each part of your solar module— from the panels, charge controller, battery, inverter, to the breaker

How to Connect an Inverter to a Battery: Step-by

Mar 11, 2025 · Step-by-Step Guide to Connecting Inverter to Battery. Identify the Battery Terminals: Locate the positive (+) and negative (-) terminals on the

How to Safely Connect a Battery to an Inverter: A

Apr 13, 2025 · Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend

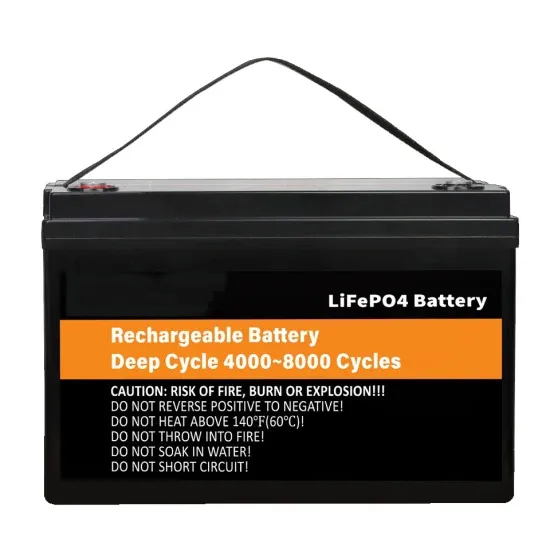

48V EEL Battery Box Inverter Connection Silicone 2M Cable

48V EEL Battery Box Inverter Connection Silicone 2M Cable 30mm² 50mm² 70mm² 4.0 (2 reviews) 8 sold Shenzhen Eel Battery Co., Ltd. Multispecialty Supplier4 yrs CN

How to Connect an Inverter to a Battery: Step-by

Mar 11, 2025 · Learn how to safely and efficiently connect an inverter to a battery with our step-by-step guide. Includes brand-specific tips for Solis, Deye,

Solar Panel to Battery & Inverter Connection Guide

Jan 9, 2024 · To connect solar panels to an inverter and batteries, you need to ensure a well-made connection. This involves following a step-by-step process

Inverter connection diagram. Install Inverter and

Nov 12, 2024 · In this article, I have tried to explain the full details about the Installation of an Inverter at our Home with a Wiring Diagram. Why we need

How to connect solar panels to inverter and

May 7, 2025 · This guide explains how to connect solar panels to an inverter safely and effectively. We''ll also discuss factors like inverter capacity to help

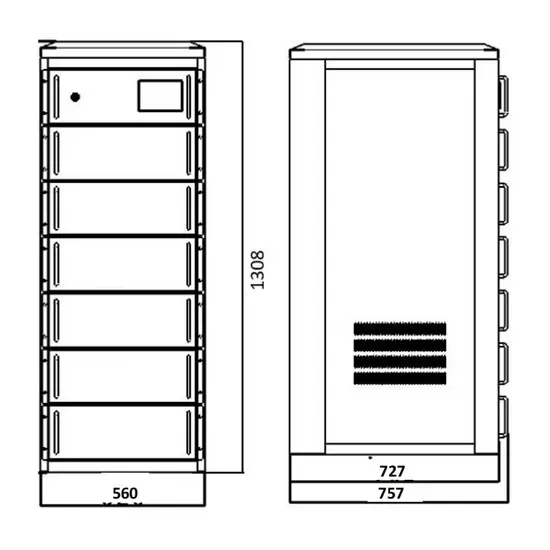

BATTERY-BOX LVS

Sep 25, 2020 · Inrush Power: Each Inverter has their Inrush power for off grid applications, please make sure to consult with inverter brands for the right value of correspondences; On-grid with

Step-by-Step Guide to Connecting an Inverter to

Oct 9, 2024 · Connecting an inverter to a distribution board (DB) is a crucial step in ensuring uninterrupted power during outages. The process begins with

Multicluster-Boxes for SUNNY ISLAND

Feb 3, 2025 · With the SMA Multicluster-Boxes for Sunny Island battery inverters, both off-grid systems and battery-backup systems* can be configured easily and cost-efficiently. In regions

How to Wire Inverter to Battery – No Sparks, Just Power

Jul 18, 2025 · How to wire an inverter to a battery? Connect the inverter''s positive and negative terminals to the battery, add a fuse on the positive line, and double-check polarity. Match

Inverter Battery Connection: Essential Tips For Safe And

Nov 16, 2024 · Connecting an inverter to a battery involves more than just attaching wires. It''s a process that requires care, precision, and adherence to safety protocols. Turn off both the

How to Connect an Inverter to a Battery Bank? –

May 29, 2023 · Step-by-Step Guide to Connecting an Inverter to a Battery Bank. 1. Ensure that the inverter is switched off and disconnected from any power

How to Wire an Inverter to Your House? A Fast

Jan 15, 2021 · If you''re planning to install an inverter in your house, you need to read this article as it breaks down the procedure into more intelligible bits. You

Inverter Battery Connection: Essential Tips For Safe And

Learn essential tips for safe and efficient inverter battery connection. Discover step-by-step guides, wiring techniques, and troubleshooting tips to optimize your power backup system''s

Connecting an inverter battery: a visual guide

To begin with, you need to connect the inverter to the AC mains. This connection allows the inverter to charge the battery when the power is available, ensuring a constant supply of

Quick Guide to How to Install Inverter and

Mar 16, 2023 · Quick Guide to How to Install Inverter and Battery at Home, As the term "power failure" is becoming more and more a reality, most people are

6 FAQs about [Battery inverter connection box]

How do you connect an inverter to a battery?

Connect the positive cable first. Attach the red cable to the positive terminal on both the inverter and the battery. Attach the negative cable. Connect the black cable to the negative terminal, ensuring secure attachment to prevent loose connections. Always use insulated tools to avoid unintentional contact with live wires.

What are inverter battery connections?

Inverter battery connections form the backbone of reliable power systems, ensuring efficient operation and safety. By following best practices and understanding the nuances of these connections, you can enhance system performance and longevity.

Can Inverter Batteries be connected in series or parallel?

Depending on the desired voltage and capacity, you can connect the inverter batteries in series or parallel. When connecting in series, connect the positive terminal of one battery to the negative terminal of the next battery, and so on.

How do you connect an inverter to a power supply?

Properly connecting these components guarantees seamless operation and extends the lifespan of your equipment. To begin with, you need to connect the inverter to the AC mains. This connection allows the inverter to charge the battery when the power is available, ensuring a constant supply of backup power.

Why do I need to connect a battery to my inverter?

Properly connecting the battery to your inverter is essential for ensuring its efficient and reliable operation. However, issues with the battery connection can sometimes arise, causing problems such as power loss or device malfunction. In this article, we have discussed various troubleshooting tips to help you diagnose and resolve these issues.

What size cable do I need for a battery inverter?

A: The thickness of the cable depends on the power level. A 4 AWG cable is commonly used for inverters smaller than 1500W, and a 2 AWG or thicker cable is commonly used for medium to high power inverters (2000-3000W). It is recommended to use multi-stranded copper core cables. Q: Do I need a fuse between the battery and the inverter?

Learn More

- Battery box with inverter

- Battery cabinet connection box

- Inverter battery connection

- What kind of battery is the Silicon Energy Inverter

- 48v inverter connection

- Inverter 12v battery

- The role of battery plus inverter

- How big is a 150A 12v battery inverter

- How much battery loss after passing through the inverter

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.