How to charge outdoor power supply with solar energy

Feb 22, 2024 · 3. CHOOSING THE RIGHT BATTERY Selecting an appropriate battery is integral to the success of utilizing solar energy for outdoor power supplies. Batteries store the energy

Charge car battery with lab bench power supply

Sep 8, 2018 · Is it possible to charge a lead acid car battery with a lab bench power supply? I am thinking of hooking it up to 13.8 Volts and 1 Amps. Will this work?

Charging Lead-Acid Batteries

Apr 28, 2024 · Charging a lead-acid battery is a matter of replenishing the amount of energy that the battery has lost during the operation. This recharging operation can be performed with

Charging of Lead Acid Battery: Methods and Precaution | Electricity

2 days ago · In this article we will discuss about:- 1. Methods of Charging Lead Acid Battery 2. Types of Charging Lead Acid Battery 3. Precautions during Charging 4. Charging and

HOW TO CHARGE LEAD ACID BATTERIES

Feb 11, 2025 · CONSTANT VOLTAGE CHARGING Constant voltage charging is the best method to charge sealed lead acid batteries. Depending on the application, batteries may be charged

HOW TO CHARGE LEAD ACID BATTERIES

Apr 16, 2024 · CONSTANT VOLTAGE CHARGING Constant voltage charging is the best method to charge sealed lead acid batteries. Depending on the application, batteries may be charged

How to charge all lead acid batteries; how to

Apr 25, 2024 · Charging voltages range between 2.15V per cell (12.9V for a "12V" 6 cell battery) and 2.35V per cell (14.1V for a "12V" 6 cell battery). These

How to Charge a Lead-Acid Battery With a Li-Ion Charger

Apr 1, 2023 · Conversely, with Li-ion batteries becoming more and more popular, semiconductor suppliers provide a rich charger portfolio for the Li-ion batteries on the market. This application

Five solutions for outdoor power supply – AllWEI

Nov 29, 2024 · However, diesel generators used to be a good choice for outdoor power supply because they operated independently of the city''s power grid. However, this was not a

Charging and discharging of lead acid battery

Aug 6, 2024 · Summarize: The charging and discharging of lead-acid batteries need daily maintenance, pay attention to the charger specifications, charging environment, charging

Can I Charge a Battery Directly from Power Supply?

Nov 3, 2022 · A power supply can charge a battery directly if the voltage and current output of the power supply is greater than or equal to the voltage and

6 FAQs about [Outdoor power supply charging lead-acid battery]

How to charge a 12 volt lead acid battery?

Before connecting the battery, calculate the charge voltage according to the number of cells in series, and then set the desired voltage and current limit. To charge a 12-volt lead acid battery (six cells) to a voltage limit of 2.40V, set the voltage to 14.40V (6 x 2.40). Select the charge current according to battery size.

How to charge a sealed lead acid battery?

current limited charging is best.To charge a sealed lead acid battery, a DC voltage between 2.30 volts per cell (float) and 2.45 volts per cell (fast) is applie to the terminals of the battery. Depending on the state of charge (SoC), the cell may temporarily be lower after d scharge than the applied voltage. After some t

Can a power supply equalize a lead acid battery?

You can also use the power supply to equalize a lead acid battery by setting the charge voltage 10 percent higher than recommended. The time in overcharge is critical and must be carefully observed. (See BU-404: What is Equalizing Charge) A power supply can also reverse sulfation.

Can lead acid batteries be overcharged?

The lead acid chemistry is fairly tolerant of overcharging, which allows marketing organizations to get to extremely cheap chargers, even sealed lead acid batteries can recycle the gasses produced to prevent damage to the battery as long as the charge rate is slow.

How to charge a lead-acid battery?

The charging method of lead-acid battery needs to choose different charging equipment according to different situations, usually the charging method of lead-acid battery has fixed-current charging, fixed-voltage charging, rapid charging (pulse charging) and so on, and it is recommended to use pulse charging, which is described as follows.

Why are flooded lead acid batteries important?

The basic lead acid battery is ancient and a lot of different charge methods have been used. In the old days, when charging voltage was difficult to regulate accurately, flooded lead acid batteries were important because the water can be replaced.

Learn More

- Base station battery to outdoor 12v power supply

- Outdoor power supply long-term charging and use

- How many volts of battery are used for outdoor power supply

- Outdoor power supply fast charging large capacity

- Charging pile to charge mobile outdoor power supply

- Extreme Control Battery Outdoor Power Supply

- What size of battery should I choose for outdoor power supply

- Is there any relationship between outdoor power supply and battery

- Lithium battery 72v outdoor power supply

Industrial & Commercial Energy Storage Market Growth

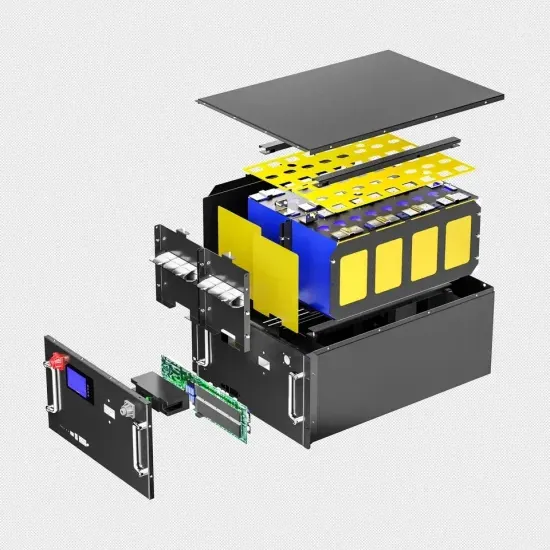

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.