How do I convert my electric water pump to solar?

The higher the HP of an electric water pump, you''ll typically need more solar panels and a larger inverter. An inverter takes power from incoming DC voltage and turns the power into AC voltage.

Will a 12v DC water pump work if directly connected to solar panels

4 days ago · Most of common DC water pumps can work directly connected to the solar panel, but their biggest problem is stuck. At dawn, the sunlight begins to change from weak to strong,

How to Build a Solar Powered Water Pump – RGardening

Aug 31, 2022 · The last step is connecting the water pump to the battery and solar panel. A good rule of thumb is that if you want to use a pump for irrigation purposes, you should have enough

How do you hook up a solar panel to a water pump?

With RPS Solar Pumps, you will connect the solar panels directly to the provided control box. The control box is the ''brains'' of the system, and will harness the power collected by the solar

Can I Connect Solar Panel Directly to Water Pump:

May 23, 2025 · The idea of connecting a solar panel directly to a water pump has gained popularity, especially among individuals looking to harness renewable energy for their

Can I Connect Solar Panel Directly to Water Pump:

May 23, 2025 · To determine if a solar panel can be connected directly to a water pump, it''s vital to understand the output characteristics of the solar panel and the power requirements of the

Connect DC Pump to Solar Panel for Efficient Water

Oct 31, 2024 · Learn how to efficiently connect a DC pump to a solar panel with our step-by-step guide. Discover the essentials needed, like a 12V DC solar water pump, black and red cables,

Solar-Powered Water Pump: Harness the Sun to Pump Water!

Solar Panels Capture Sunlight – The solar panel absorbs sunlight and converts it into electricity. Power is Sent to the Pump – The generated electricity powers a DC water pump.

What Kind of Solar Inverter Can Drive a Water

Dec 4, 2023 · 1. Solar Pump Inverter A solar pump inverter is a specialized type of inverter designed explicitly for operating water pumps using solar power. It

Set Up a Small Solar Water Pump: Everything

Mar 15, 2024 · It is generally not recommended to connect a water pump directly to a solar panel. Use a solar panel system to turn the direct current (DC) from

Guide to Solar Panels and Water Heating | Eco

Jan 6, 2025 · Standard photovoltaic solar panels can be used to power electric water heating systems like immersion heaters or electric boilers. Essentially,

How To Pair Solar Panels with Your Pump

Aug 4, 2025 · When considering solar water pumping, pairing solar panels with the right pump inverter is critical for efficiency and reliability. This ensures that

Can You Run a Well Pump on Solar: 6 Factors to

Aug 7, 2023 · By harnessing the power of the sun, you can power your well pump and ensure a continuous water supply, even in off-grid areas. Several factors

Solar powered water pumping systems for irrigation: A comprehensive

Jan 1, 2020 · The electricity deficit and higher fuel costs affect the water supply to irrigation requirements. Solar energy for water pumping is a promising alternative to conventional

How to Connect Solar Panel to Water Pump

Nov 17, 2023 · In this guide, we will explain how to connect a solar panel to a water pump so that you can easily draw power using sunlight. Water pumps play a vital role in our lives, helping us

8 Tips for Solar Water Pump Installation (For

Dec 14, 2023 · Installing a Solar water pumps solar water pump involves a series of steps. It starts with determining the ideal location for the pump, ensuring

6 FAQs about [Solar panel connected to water pump]

How to connect a solar panel to a water pump?

To connect a solar panel to a water pump, several steps must be followed : Before you start connecting your solar panel to a water pump, you need to identify the power requirements of your pump. This information is usually specified by the manufacturer and is measured in horsepower (HP) or kilowatts (kW).

Can solar panels run a water pump?

Solar panels provide a fantastic opportunity to decrease your ecological footprint and save on electricity bills. One of the numerous applications of solar panels is running water pumps. So, how does one connect solar panels to a water pump? Let’s dive deep into this enlightening journey!

How do you connect a solar pump inverter to a water pump?

Connection: Attach the solar panel wires to the solar pump inverter’s input terminals. When is it Necessary: If your water pump runs on AC power and your solar panels produce DC power. Process: Connect the output from the solar charge controller to the inverter. Then, connect the inverter to the pump.

How do I choose a solar water pump?

Evaluate Sunlight Exposure: Ensure the location of your solar panels receives ample sunlight. Decide on the Panel Capacity: Determine how much power you need to run your water pump. Select the Right Water Pump: Ensure it's compatible with your chosen solar panel capacity.

How do I connect a solar water pump to a pond?

This allows residual electricity from the batteries to flow, which the pump will use. For a single DC-powered system (e.g., a small pond or fountain), you can directly attach a single solar cell to its frame without backup batteries. Step 2: Connect the black cable to the negative connector on the solar water pump.

How does a solar power pump work?

The pump is powered by solar panels that convert sunlight into electricity. Since the voltage of the solar panel is about 16 volts and the voltage of the pump is mostly only 12-14 volts, the current flowing between the two devices is because of their different voltage levels.

Learn More

- 12v solar panel connected to 12v water pump

- 480w solar panel with 12v water pump

- Solar panel water pump storage

- Can a solar panel alone drive a water pump

- Electric water pump solar panel circulation

- Dual solar panel water pump

- How big a solar panel do I need for a 6w water pump

- 100w solar panel with water pump

- Can a 20W water pump be paired with an 80W solar panel

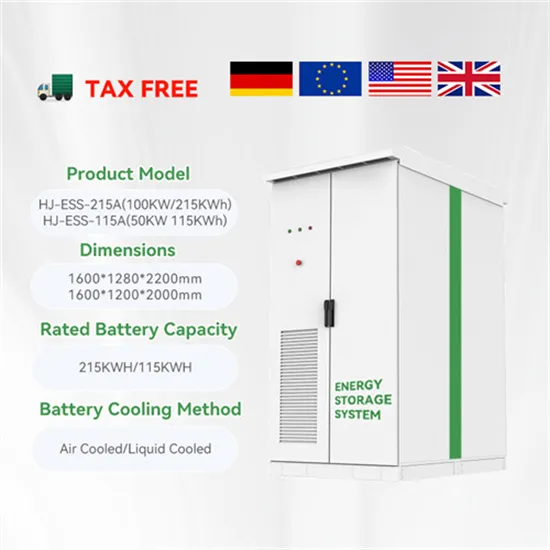

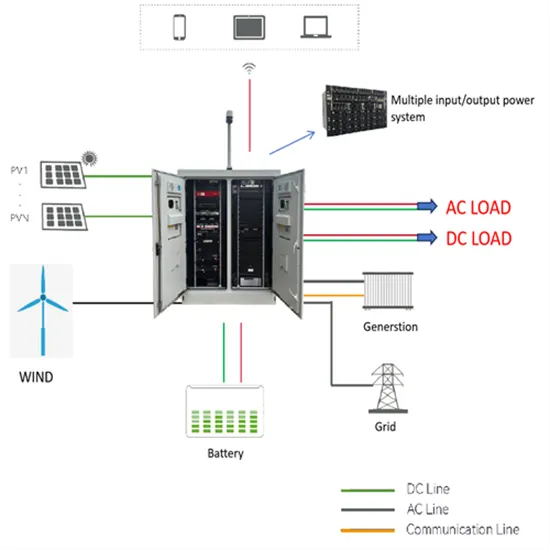

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.