How can energy storage power stations reduce

Jul 24, 2024 · Energy storage effectively addresses the dual challenges of valley reduction and peak filling. Valley reduction refers to minimizing excess energy

Peak shaving and valley filling energy storage project

2 days ago · This article will introduce Grevault to design industrial and commercial energy storage peak-shaving and valley-filling projects for customers.

Which factories need energy storage resources?

Aug 3, 2024 · Implementing energy storage technologies allows these factories to create a buffer against supply uncertainties by storing energy during off-peak

What factories produce energy storage products? | NenPower

Apr 17, 2024 · 1. A multitude of factories globally manufacture energy storage products, 2. These facilities range from established giants in the energy sphere to innovative startups, 3. Key

Commercial and Industrial Energy Storage: A Key

Mar 7, 2025 · Commercial and industrial energy storage is an effective solution to power challenges for factories in Pakistan. It improves power stability, reduces

C&I energy storage to boom as peak-to-valley spread

Aug 31, 2023 · In China, C&I energy storage was not discussed as much as energy storage on the generation side due to its limited profitability, given cheaper electricity and a small peak-to

How can power-rationed factories cope with energy storage?

Feb 7, 2024 · Moreover, thermal energy storage techniques, which involve storing heat or cold for later use, have gained traction. These methods harness excess energy for heating water or

How Can Factories Reduce Energy Costs with Peak Shaving?

The first step in any peak shaving strategy is identifying peak demand periods. These are times when energy consumption is at its highest, often coinciding with specific hours of the day or

Peak-valley off-grid energy storage methods

Achieving carbon-free electricity for all can be facilitated by setting up small to medium-scale off-grid renewable energy systems (RES); however, the variability of renewable energy sources

Which factories are suitable for installing energy

Jan 13, 2024 · Factories suitable for installing energy storage are those with high energy demands, varying energy use throughout the day, and commitment to

Scheduling Strategy of Energy Storage Peak-Shaving and Valley

Dec 20, 2021 · In order to make the energy storage system achieve the expected peak-shaving and valley-filling effect, an energy-storage peak-shaving scheduling strategy consi

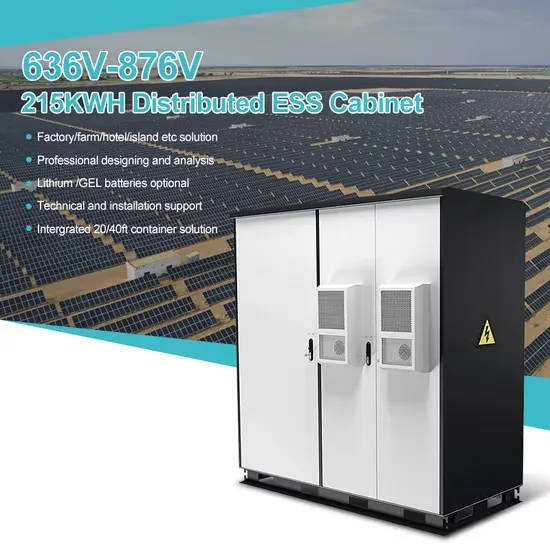

Which factories are energy storage cabinets suitable for?

Jan 26, 2024 · Energy storage cabinets are suitable for 1. manufacturing facilities, 2. renewable energy sectors, 3. data centers, and 4. electric vehicle charging stations. These cabinets serve

Powering the Future: Smart Energy Storage for Factories and

Why Energy Storage Matters Now More Than Ever the way we power our factories and homes is changing faster than a Tesla''s 0-60 acceleration. With factory energy storage equipment

How Battery ESS Containers Help Industrial Users Maximize Peak

Feb 13, 2025 · This is where the Battery ESS Container becomes a strategic tool for optimizing energy use, especially in peak shaving and valley filling applications. These energy storage

Why Factories Are Betting Big on Energy Storage Equipment

A car factory in Detroit suddenly loses power during a heatwave. Instead of halting production for hours, it switches to its giant "energy piggy bank"—a lithium-ion battery system—and keeps

Industrial Energy Storage Equipment Strength: Powering

Aug 1, 2025 · If you''re managing a factory, warehouse, or industrial park, here''s a fun fact: Your electricity bill might be leaking money like a sieve during peak hours. Industrial energy storage

Optimization Strategy of Constant Power Peak Cutting

Nov 21, 2019 · The protection of battery energy storage system is realized by adjusting the smoothing time constant and power limiting in real time. Taking one day as the time scale and

Why Factories Are Installing Energy Storage Systems: A 2024

Sep 20, 2024 · The Nuts and Bolts of Factory Energy Storage How It Works (Without the Engineering Jargon) Think of energy storage systems as a factory''s "snack drawer" – storing

Peak Shaving and Valley Filling with Energy Storage Systems

Aug 18, 2025 · Peak shaving and valley filling refer to energy management strategies that balance electricity supply and demand by storing energy during periods of low demand (valley) and

3 FAQs about [Peak and valley energy storage equipment for factories]

Do energy storage systems achieve the expected peak-shaving and valley-filling effect?

Abstract: In order to make the energy storage system achieve the expected peak-shaving and valley-filling effect, an energy-storage peak-shaving scheduling strategy considering the improvement goal of peak-valley difference is proposed.

Does constant power control improve peak shaving and valley filling?

Finally, taking the actual load data of a certain area as an example, the advantages and disadvantages of this strategy and the constant power control strategy are compared through simulation, and it is verified that this strategy has a better effect of peak shaving and valley filling. Conferences > 2021 11th International Confe...

How is peak-shaving and valley-filling calculated?

First, according to the load curve in the dispatch day, the baseline of peak-shaving and valley-filling during peak-shaving and valley filling is calculated under the constraint conditions of peak-valley difference improvement target value, grid load, battery power, battery capacity, etc.

Learn More

- Peak shaving and valley filling energy storage microgrid

- Peak Valley Energy Storage Power Station Inspection

- Sukhumi Valley Electric Energy Storage Equipment

- Energy storage battery peak and valley at home

- Energy Storage Solution Peak and Valley

- Energy storage device for valley power and peak power

- Peak and valley electricity price energy storage battery

- Energy storage cabinet peak and valley electricity and photovoltaic

- Georgia DC energy storage equipment prices

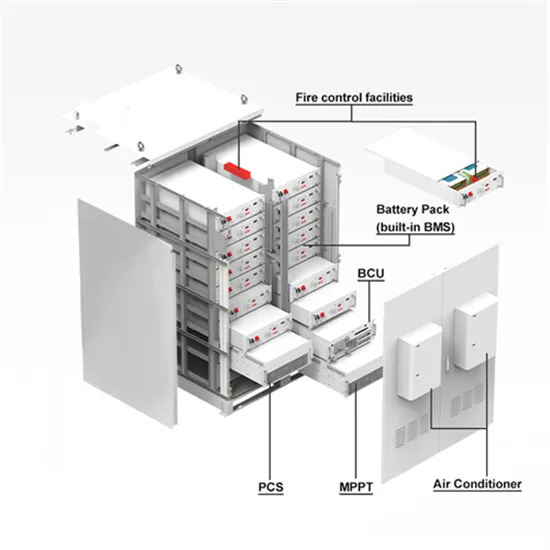

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

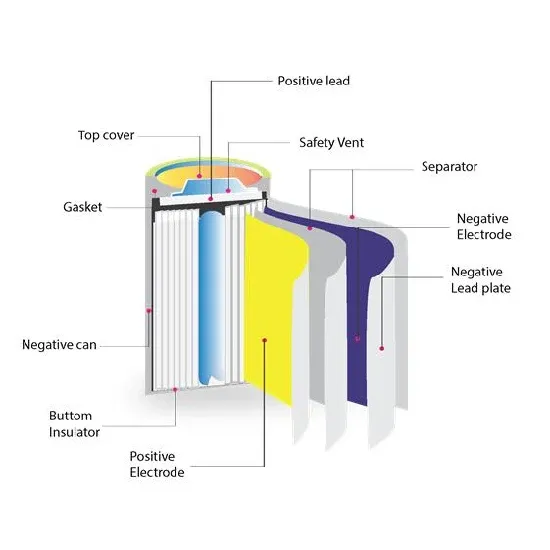

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.