Reassessment of the potential for centralized and distributed

Jan 1, 2023 · The factors considered in selecting the areas suitable for photovoltaic power generation were economy, terrain, environment for the centralized stations; illumination time,

Large utility-scale photovoltaic solar power plant grounding

Oct 5, 2015 · This paper presents basic guidelines on design considerations for large utility-scale photovoltaic (PV) solar power plant (SPP) substation and collector groundi

Photovoltaic power station bracket grounding

The focus of the guide is on differences in practices from substation grounding as provided in IEEE Std 80. Why is proper grounding of a photovoltaic power system important? Proper

Photovoltaic solar power generation system grounding

A safe and cost-efficient grounding system design of a 3 MWp photovoltaic power station according to IEEE Std 80-2000 is presented. Grounding analysis is performed by considering

Impact of grounding fault in PV modules on

1Introduction With the breakthrough of solar energy conversion technologies and the support from relevant incentive policies, photovoltaic (PV) power generation is making a spurt of progress,

Grounding Overvoltage Relay Connection Error Causes

The grounding over-voltage relay (OVGR) set on the grid-connected equipment is responsible for shutting down the inverter (PCS) after detecting the fault and stopping the power supply

The role of photovoltaic power generation system grounding

Apr 6, 2024 · According to the electrical installation safety regulations, the metal frame of the photovoltaic power generation device with the metal frame module must be grounded. If the

Ground power station photovoltaic inverter

Jul 3, 2021 · About Ground power station photovoltaic inverter As the photovoltaic (PV) industry continues to evolve, advancements in Ground power station photovoltaic inverter have

Inverter Transformers for Photovoltaic (PV) power plants:

Dec 22, 2022 · In this paper, the author describes the key parameters to be considered for the selection of inverter transformers, along with various recommendations based on lessons

SAFE GROUNDING SYSTEM DESIGN FOR A PHOTOVOLTAIC POWER STATION

Photovoltaic power station with energy storage flywheel Energy storage and power conditioning are the two major issues related to renewable energy-based power generation and utilisation.

Large Utility-Scale Photovoltaic Solar Power Plant

BASIC SOLAR POWER PLANT GROUNDING DESIGN The design of utility-scale SPP grounding systems falls between existing grounding standards for generation plants and substations.

Grounding a PV System

Aug 20, 2018 · Ground a PV System means connecting part of your system structure and/or wiring electrically to the earth. During lightning storms, the clouds build up a static electric charge.

Energy coordinated control of DC microgrid integrated incorporating PV

Jul 15, 2023 · The power of the PV power generation and EV charging units in the integrated standalone DC microgrid is uncertain. If no reasonable countermeasures are taken, the power

A methodology for an optimal design of ground-mounted photovoltaic

May 15, 2022 · A methodology for estimating the optimal distribution of photovoltaic modules with a fixed tilt angle in ground-mounted photovoltaic power plants has

Photovoltaic power generation grounding bracket

What is a solar substation grounding guide? Abstract: This guide is primarily concerned with the grounding system design for photovoltaic solar power plants that are utility owned and/or utility

Understanding Grounding in Photovoltaic Power Systems

Apr 7, 2024 · Discover the indispensable role of proper grounding in photovoltaic systems. Learn how it mitigates risks from electric shocks to lightning strikes, ensuring both personnel safety

104 FLOATING SOLAR HANDBOOK FOR PRACTITIONERS

Mar 14, 2020 · IEC 62920: 2017 Photovoltaic power generating systems—EMC requirements and test methods for power conversion equipmen IEC TS 61724-1, 2, 3: 2016/2017 Photovoltaic

Optimal configuration for photovoltaic storage system

Oct 1, 2021 · Base station operators deploy a large number of distributed photovoltaics to solve the problems of high energy consumption and high electricity costs of 5G base stations. In this

6 FAQs about [Outdoor base station photovoltaic power generation grounding]

Does your PV system need a grounding?

PV systems, especially rooftop installations, are exposed to lightning strikes and electrical surges year-round. Without proper grounding, these risks can lead to system damage, fire hazards, and operational downtime. Bluesun Solar emphasizes professional grounding designs to protect systems and ensure long-term reliability.

Why is proper grounding important for photovoltaic systems?

Proper grounding is a critical safety measure for photovoltaic (PV) systems. With advances in solar technology, companies like Bluesun Solar are leading the way in offering innovative and reliable grounding solutions to safeguard PV systems from lightning and electrical risks.

What are the challenges of PV grounding design?

One of the challenges in designing the grounding for a Utility Scale Photovoltaic Power Plant is understanding how the system is actually connected, as there are different configurations. In many such systems, the grounding system is common from the DC grounding conductors and the AC grounding conductors.

What is a ground-mounted PV system?

Ground-Mounted PV Systems: These systems have grounding systems designed to cater specifically to their exposure to environmental electrical risks. The success of these designs is seen in the minimal disruption to service despite ground-mounted systems’ high exposure to lightning strikes.

Can a 3 MWp photovoltaic power station be grounded according to IEEE Std 80-2000?

A safe and cost-efficient grounding system design of a 3 MWp photovoltaic power station according to IEEE Std 80-2000 is presented. Grounding analysis is performed by considering the metal parts of the photovoltaic panel arrays foundations as auxiliary ground electrodes.

What is grounding a power system?

It’s the method of electrically connecting the neutral point of a power system, including various installations and the conductive elements of electrical equipment directly to the earth through grounding conductors. Why Is Grounding Essential?

Learn More

- Dili Communication Base Station Inverter Grid-connected Photovoltaic Power Generation Outdoor Unit

- East Asia Communication Base Station Inverter Grid-connected Photovoltaic Power Generation Quotation

- Communication base station solar photovoltaic power generation manufacturer

- Nordic communication base station inverter photovoltaic power generation equipment

- Accra 5g base station photovoltaic power generation system communication cabinet

- What are the parameters of photovoltaic power generation of communication base station batteries

- Tehran Communication Base Station Photovoltaic Power Generation System Solution

- Photovoltaic power generation 5g base station

- Base station outdoor integrated cabinet base station power generation

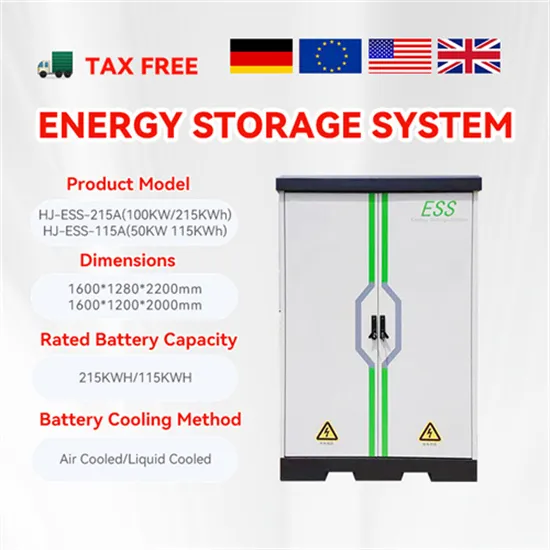

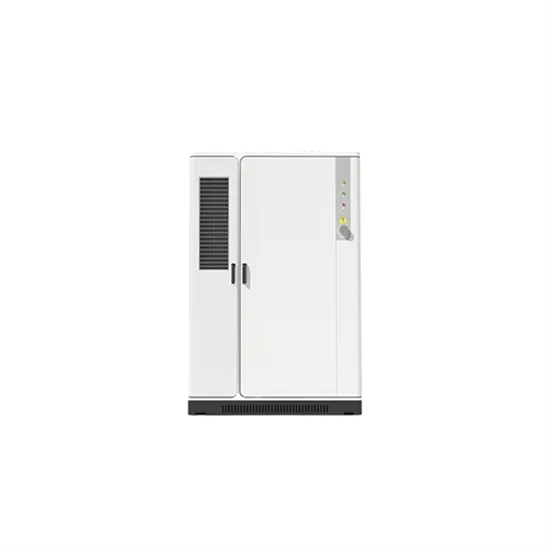

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.