Wireless Communication Base Station Location Selection

Jun 9, 2024 · 1. Introduction Recently, with the rapid development of wireless communication technology, the enhancement of wireless network performance is concerned with meeting the

Connecting Wind Farms: Making True Mission-Critical

Feb 21, 2024 · These radiating cables combine highly reliable communication with a maintenance-free operation and a lifespan that lasts decades. This makes it the ideal option

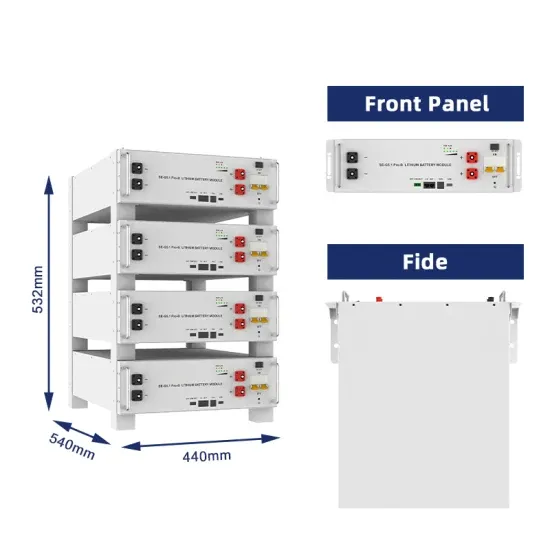

Energy storage system of communication base station

Energy storage system of communication base station Base station energy cabinet: floor-standing, used in communication base stations, smart cities, smart transportation, power

Strategy of 5G Base Station Energy Storage Participating in the Power

Mar 13, 2023 · The proportion of traditional frequency regulation units decreases as renewable energy increases, posing new challenges to the frequency stability of the power system. The

Communication Base Station Maintenance Guide | HuiJue

Why Your Network Stability Hinges on Proactive Maintenance Did you know a single communication base station failure can disrupt services for 5,000+ users? As global 5G

Research on Offshore Wind Power Communication System

Feb 5, 2024 · This system can help plan and sort out the wind turbine subsystems, realize all-round signal coverage inside the wind turbine, and can quickly and safely transmit the

Research of Preventive Maintenance Plans for Wind Power

Jan 1, 2024 · In this case, we propose a preventive maintenance plan generation method for wind power equipment based on maintenance knowledge fusion large model. Our solution

Environmental Monitoring of Communication Base Station

Dec 19, 2020 · To improve the management and maintenance level of communication base stations, according to the actual requirements of environmental monitoring of communication

Comprehensive Review of Intelligent Operation and Maintenance of Power

Jun 29, 2021 · For the converter station''s main equipment and monitoring system, the current situation and requirements of intelligent operation and maintenance are analyzed from the

Wind Turbine Technician Core Competencies

Jan 22, 2021 · Their extensive knowledge and experience pertaining to the safe operation and maintenance of electrical components found at wind power facilities formed the basis of this work.

Base Station System Structure

Jan 28, 2011 · 1 Introduction This document is a compilation of documents developed in the Base Station Working Group. It describes the structure of base station systems with a convergent

Reliable Communication System for Wind Power Plants: A

Reliable communication between maintenance crews and control centers is critical — especially during turbine malfunctions or scheduled inspections. Traditionally, operators relied on analog

Multi-objective cooperative optimization of

This paper develops a method to consider the multi-objective cooperative optimization operation of 5G communication base stations and Active Distribution Network (ADN) and constructs a

Wind Data Logging and Validation Using

Nov 30, 2016 · To identify a BS station that shares a common wind current with a nearby conventional meteorological station and set up a data logger using the BS infrastructure to

Mobile communication base station power supply equipment maintenance

Oct 14, 2022 · The base station power system is one of the supporting support systems for mobile main equipment and transmission equipment, involving various professional subjects such as

6 FAQs about [Communication base station wind power maintenance work plan]

Can wind energy be used to power mobile phone base stations?

Worldwide thousands of base stations provide relaying mobile phone signals. Every off-grid base station has a diesel generator up to 4 kW to provide electricity for the electronic equipment involved. The presentation will give attention to the requirements on using windenergy as an energy source for powering mobile phone base stations.

Do wind turbines need communication infrastructure?

However, there are several aspects that make the deployment of communication infrastructure in wind turbines and across wind farms more challenging. The location of wind turbine sites immediately increases the complexity of delivering connectivity. Remote rural sites and off-shore sites mean using standard cellular connectivity is not viable.

Why should you choose a radiating cable for a wind turbine?

These radiating cables combine highly reliable communication with a maintenance-free operation and a lifespan that lasts decades. This makes it the ideal option for achieving connectivity that spans the entire height of a wind turbine or gives complete substation coverage in both on-shore and off-shore environments.

Does your wind farm need a quality coverage plan?

Wind farm operations need comprehensive and, importantly, consistent communication to be able to make the most of their energy-generating assets. From remote monitoring to predictive maintenance that ensures minimal downtime, there is a need for quality coverage, but what does that look like?

How do wind turbine owners deliver contoured coverage?

Instead, wind turbine owners need to look at how to deliver contoured coverage. Contoured coverage takes into consideration all potential barriers to connectivity and, by design, uses equipment that works around this to ensure full site coverage. One of the most efficient ways of doing this is to use a solution like RFS’s RADIAFLEX.

Do wind turbine sites need cellular connectivity?

The location of wind turbine sites immediately increases the complexity of delivering connectivity. Remote rural sites and off-shore sites mean using standard cellular connectivity is not viable. Instead, there needs to be investment in a private wireless solution to give the coverage needed to operate effectively.

Learn More

- Maintenance plan for wind power and photovoltaic power generation at communication base stations

- Sophia Communication Base Station Wind and Solar Complementary Power Generation Maintenance

- 5g communication base station wind power layout

- What does wind power and photovoltaic power generation include in Antananarivo communication base station

- Communication Green Base Station Maintenance Power Saving

- Liechtenstein communication base station wind power cooling chassis

- Communication base station hybrid energy wind power algorithm

- Communication base station wind power signal box

- Communication base station wind power Three-point wind power

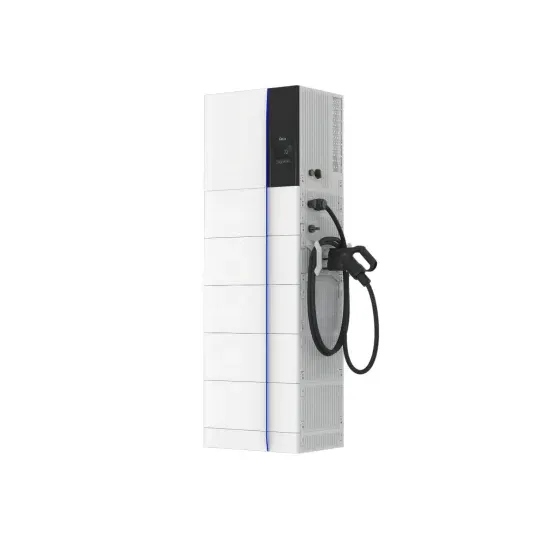

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.