CBWI August 1996 Proper Base Station & Mobile Grounding

Aug 4, 2023 · Proper Base Station & Mobile Grounding Proper grounding of your equipment is very important. Not only in performance but if you''re running high power there are health risks

Grounding DC Power Supplies | Support of ACE

This article explores the benefits and drawbacks of grounding DC power supplies DC power supplies are a common — perhaps almost guaranteed — component of a control system,

How to Ground a Power Supply

Jan 21, 2025 · Grounding a power supply is an essential part of any electrical installation, providing safety, equipment protection, and improved system performance. By understanding

How to Ground a Power Supply

Jan 21, 2025 · Grounding a power supply is a critical aspect of ensuring safety, efficiency, and reliability in electrical systems. Grounding provides a path for stray electricity to safely

Building better power supplies for 5G base stations

May 25, 2025 · Building better power supplies for 5G base stations Authored by: Alessandro Pevere, and Francesco Di Domenico, both at Infineon Technologies Infineon Technologies -

The Station Ground System

Jul 2, 2010 · The station electrical, and to a lesser extent the RF, grounding system provide protection against hazards from equipment and lightning in the shack. However, the use of

Station / Antenna Grounding

Aug 13, 2023 · Grounding your radio is not necessary, if it is powered by AC, it should meet electrical code and not need any further grounding. If it is powered by 12 volts DC, then the

How a Rail Grounding System Protects Infrastructure

Dec 23, 2024 · This includes the rails, power supply equipment, signaling systems, and station equipment. The goal is to ensure that any electrical faults are safely diverted through the

Should a Power Supply Be Grounded?

6 days ago · The question of grounding a power supply is fundamental to electrical safety and proper equipment function. While the simple answer is almost always a resounding "yes,"

Appendix D Equipment Grounding Specifications

The grounding resistance of a comprehensive communication building should be less than or equal to one ohm. The grounding resistance of an ordinary communication office should be

Base station energy storage bms ground negative pressure

Grounding considerations for Battery Management Systems (BMS) in battery-operated environments are crucial for ensuring safety,functionality,and accurate battery monitoring. Key

Grounding for a Portable Power Station?

May 22, 2020 · For a portable power station I don''t see why you would earth ground it when it''s meant to be mobile, so the only choice I see is using GFCI which you already are doing. Not

Lightning protection solutions for mobile base stations

Jun 28, 2020 · 1. Lightning protection of base station power supply At present, the AC power of the mobile base station is mainly provided by the municipal power grid. Due to the instability

Maintenance of communication base station power supply

This article discusses how to improve the power supply safety of the power supply system of communication base stations, reduce the failure rate of the power supply system of

6 FAQs about [Base station power supply grounding]

Why is a grounding system important for a high-powered radio station?

A proper grounding system is one of the most critical aspects of setting up a high-powered amateur radio station. It not only ensures safety but also helps in achieving optimal performance of your equipment by reducing interference, protecting your gear, and preventing damage from lightning strikes or power surges.

How do I design a grounding system for a high-powered station?

When designing a grounding system for a high-powered station, there are several technical factors to consider: Grounding Resistance: The resistance between your grounding system and the earth should be as low as possible, typically under 10 ohms, but ideally below 5 ohms for optimal safety.

Why do I need a grounding system?

Grounding serves several essential purposes: Lightning Protection: High-power transmissions can attract lightning, and a good grounding system will safely redirect this electrical energy into the earth, reducing the risk of damage to your station and property.

What equipment should be grounded in a TR?

The server and supporting equipment (such as mobile base stations, switches, and power supplies) in the TR should be grounded. The protection ground (PGND) cables of the equipment in the communication office should be finally connected to the total ground bar.

Does a 24V DC power supply need to be grounded?

So, the short answer for some 24V DC systems is no, the output is not required to be connected to ground. From the UL 508A specification, there are further answers that also dictate grounding depending on the input voltage of the power supply. Figure 1. Grounding power supplies inside a control cabinet can be a difficult decision.

How do you maintain a grounding system?

Avoid sharp bends and long runs, as these can introduce unnecessary resistance. Regular Maintenance: Over time, grounding systems can degrade due to corrosion, especially in areas with high humidity or salty air. Periodically check the condition of your grounding rods and wire, and re-tighten connections as needed.

Learn More

- Base station wind power supply working grounding

- Base station energy storage power supply latest price

- Base station power supply calculation

- Base station communication power supply type

- Hybrid power supply of battery energy storage system for Saint Lucia communication base station

- 5g Base Station Power Supply Bureau

- Communication base station power supply transformation plan

- 5g base station installation with power supply

- Communication base station communication high voltage DC power supply

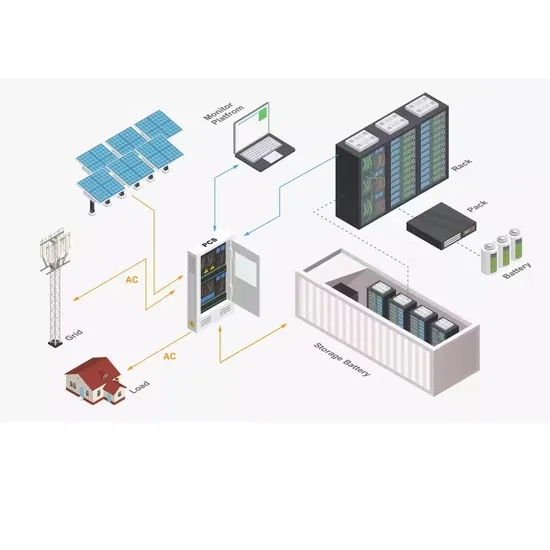

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

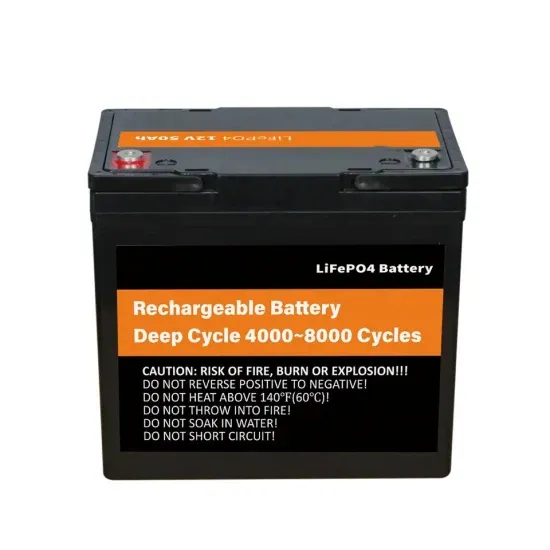

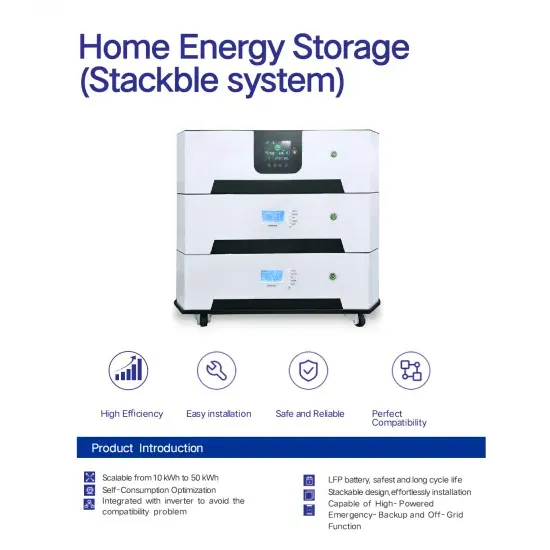

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.