Integration of Solar Energy in Construction: The

Dec 15, 2023 · Solar-integrated buildings, equipped with photovoltaic (PV) solar panels, possess a transformative capability to generate their electricity. This

What solar panels are used in factories to

May 25, 2024 · Factories primarily utilize photovoltaic (PV) solar panels for electricity generation, consisting of crystalline silicon, thin-film, and bifacial

Can photovoltaic panels be installed in factories

Can a solar PV system be installed on a factory roof? As factories are energy-intensive buildings,installing a solar PV system on the roof of a factoryensures free power can be

Are there high requirements for installing photovoltaic

As factories are energy-intensive buildings,installing a solar PV system on the roof of a factoryensures free power can be generated to run everything underneath it. While reducing

Solar Energy in Warehouses and Manufacturing Facilities

Jun 20, 2025 · By generating independent power on their rooftops, warehouses and factories reduce their reliance on the National Grid. This means that if there are grid constraints or

Solar Photovoltaic Panels for Industrial Applications

Sep 6, 2024 · Solar photovoltaic (PV) systems can be installed onsite to provide renewable power to serve facility electrical loads, including industrial processes. Deploying solar PV for

Which factories can be equipped with photovoltaic panels

Sloped Roofs: Solar panels can be installed using the appropriate mounting system that matches the roof''''s pitch for sloped factory or warehouse roofs. This ensures the PV panels are

Solar Energy in Warehouses and Manufacturing Facilities

Jun 20, 2025 · 2. Energy Security and Operational Resilience Solar panels improve a facility''s energy security, making it less vulnerable to external supply disruptions. By generating

Why Solar Energy is Critical for Sustainable Warehouse

Oct 16, 2024 · This can lead to further energy savings and operational efficiencies. Automated Controls: Use smart systems to manage energy use dynamically, ensuring that solar energy is

Empowering Factories with Solar Energy A Strategic Tool for

Apr 17, 2025 · For energy-intensive factories, owning part of their solar power generation can significantly reduce peak electricity purchase costs, lessen dependence on grid fluctuations,

Can solar panels be used in factories

Commercial solar installations on the roofs of factories increase industrial energy efficiency. When a factory has a commercial solar power system, the energy required by the building can be

Are all factory roofs equipped with photovoltaic panels

As factories are energy-intensive buildings, installing a solar PV system on the roof of a factory ensures free power can be generated to run everything underneath it. They enacted Assembly

What are the factories that make solar panels? | NenPower

Mar 8, 2024 · In the realm of renewable energy, solar panels stand out as a significant technology for harnessing sun rays to generate electricity. Numerous factories worldwide manufacture

Solar Inverters with MPPT Controllers: Unlocking New

1 day ago · Solar Inverters with Mppt Controller s: Unlocking New Heights in Photovoltaic System Efficiency Amid the accelerating global energy transition, solar energy, one of the most

What is Industrial Size Solar Panel? A Comprehensive Guide

Feb 8, 2025 · Industrial solar panels not only offer a pathway to sustainable energy but also provide economic benefits that can enhance a company''s bottom line. Transitioning to solar

Can a solar system power a factory?

By generating their own electricity, factories can significantly cut down on their energy bills. Moreover, solar panels require minimal maintenance, further contributing to cost savings.

Unlocking Solar Power: Can Factories be Energised

Solar panels can effectively power factories, transforming sunlight into usable electricity thanks to the photovoltaic effect discovered in 1839. Energy consumption of factories can be calculated

How to use solar energy in factories | NenPower

Sep 18, 2024 · Apart from photovoltaic technology, solar thermal systems represent another pathway for factories to utilize solar energy. These systems capture sunlight to produce

Solar Energy For Warehouses & Distribution

3 days ago · A warehouse can install solar panels in other areas if its roof space is limited. A warehouse roof facing south is the best place for solar installation,

How to install photovoltaic panels and wires in factories

As factories are energy-intensive buildings,installing a solar PV system on the roof of a factoryensures free power can be generated to run everything underneath it. While reducing

6 FAQs about [Can factories be equipped with photovoltaic solar panels ]

What are solar panels for industrial use?

Solar panels for industrial use represent a transformative approach to energy consumption in factories, offering a sustainable and cost-effective solution to meet growing energy demands. By harnessing the power of the sun, industries can significantly reduce their carbon footprint, lower operational costs, and enhance energy independence.

Why do factories use solar panels?

Furthermore, with advancements in solar technology, the efficiency and longevity of solar panels have improved, making them a more reliable source of energy over time. In addition to direct savings on energy costs, factories can also benefit from various financial incentives offered by governments and local authorities.

Is solar power the future of manufacturing?

As manufacturing plants look to reduce costs and minimize their environmental footprint, solar energy emerges as a powerful solution. Solar power doesn’t just replace traditional energy sources—it redefines the way factories operate, combining advanced engineering with environmental responsibility to create smarter, greener industrial processes.

Is solar PV a good option for industrial applications?

Deploying solar PV for industrial applications is desirable because it is cost-effective and aligns with organizational environmental goals and environmental regulations. Deploying solar PV systems onsite can reduce energy costs, reduce emissions, and (when combined with battery storage) provide backup power.

Are solar panels a viable option for factories?

As technology advances and efficiency improves, solar panels are becoming an increasingly viable option for factories looking to innovate and lead in sustainability. The integration of solar panels into industrial operations is increasingly recognized as a strategic move for factories aiming to reduce operational expenses.

Are solar panels a good investment for a factory?

In addition to direct savings on energy costs, factories can also benefit from various financial incentives offered by governments and local authorities. Tax credits, rebates, and grants can significantly reduce the overall cost of solar panel installation, making it an even more attractive option for manufacturers.

Learn More

- Bus stations in Ecuador equipped with solar photovoltaic panels

- Can solar photovoltaic panels be equipped with water pumps

- How many solar photovoltaic panels are there in one set

- Solar Monitoring Photovoltaic Panels in North America

- Solar photovoltaic panels plus lithium batteries

- What are photovoltaic panels and what are solar cells

- Maximum power of photovoltaic solar panels

- Monocrystalline silicon photovoltaic panels solar energy

- Feasibility of solar photovoltaic panels for home use

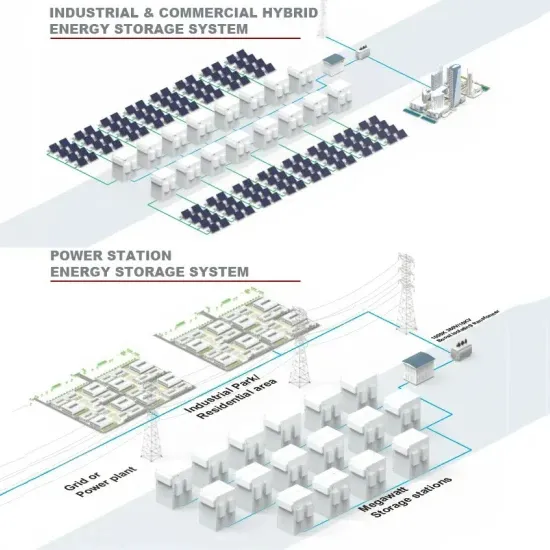

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.