Pure vs. Modified Sine Wave Inverters: Which Is Best?

Aug 24, 2024 · However, if you''re only powering basic items like lights, fans, or simple tools, a modified sine wave inverter might suffice. Final Thoughts: Which Inverter Should You Buy?

Pure Sine Wave Inverter vs Modified (What You

Nov 1, 2023 · Modified sine wave inverters are similar to pure ones but aren''t the same. Modified inverters create a sine wave that''s easy to produce but not as

Pure Sine Wave vs. Modified Sine Wave Inverters

There are three major types of sine inverters - pure sine wave (or "true" sine wave), modified sine wave (actually a modified square wave) and square wave. Each of these types of inverters

Pure Sine Wave Inverter: All You Need to Know

May 10, 2023 · In this blog post, we will explore the fundamentals of pure sine wave inverters, including what they are, how they work, the differences between modified and pure sine wave

Do I need a Modified Sine Wave Inverter, or a Pure Sine Wave Inverter?

a) Output voltage wave form is pure sine wave with very low harmonic distortion and clean power like utility-supplied electricity. b) Inductive loads like microwave ovens and motors run faster,

Differences Between Pure Sine Wave and Modified Sine Wave Inverters

Pure sine wave inverters offer superior power quality compared to their modified counterparts, resulting in higher efficiency ratings. Generally, pure sine wave inverters exhibit efficiency

Modified or Pure Wave? Projecta''s Guide to Power Inverters

6 days ago · The key difference between modified and pure sine wave inverters comes down to how closely they replicate 220–240V mains power. Pure sine wave inverters produce power

What are the Differences: Pure Sine Wave Inverter vs Modified Sine Wave

Oct 12, 2024 · Pure sine wave inverter: It produces a smooth, continuous waveform that closely resembles the AC power provided by the utility grid. The waveform is a true sine wave with a

Modified vs pure sine wave inverters – a detailed comparison

5 days ago · Differences of modified sine wave inverter vs pure sine wave inverter: Output Waveform. Modified Sine Wave Inverter: Produces a stepped or modified waveform with sharp

What Is a Pure Sine Wave Inverter and How Does It Work?

A pure sine wave inverter is a specialty device that transforms direct current (DC) electricity from sources like batteries or solar panels into alternating current (AC) electricity, generating a

Modified vs Pure Sine Wave Inverters: Which Is

Jun 6, 2025 · Inverters are at the heart of modern power systems, especially in off-grid, renewable, and backup power applications. Understanding the types

How to Check If Your Inverter Is Pure Sine Wave:

Mar 11, 2025 · Why pure sine wave inverter matters? Pure sine wave inverters are suitable for all kinds of electronic devices, especially sensitive devices that

6 FAQs about [Modified inverter pure sine wave]

What is the difference between pure sine wave inverter and modified sine wave?

Pure sine wave inverters and modified sine wave inverters are two common types of inverters. They have some differences in working principle, performance characteristics, application field, waveform, and compatibility. Next, we will explain the differences between pure sine wave inverters and modified sine wave inverters in various aspects.

What is a pure sine wave inverter?

High-Quality Output: Pure sine wave inverters deliver a high-quality, smooth, pure and continuous waveform that closely replicates utility grid power. Efficiency: They are highly efficient and often outperform modified sine wave inverters in this aspect.

What is a modified sine inverter?

The major advantage of modified sine inverters is that they are less expensive than pure sine models. Pure sine inverters are more sophisticated devices that can exactly replicate an AC sine wave from a DC power source. Because of their added complexity, they've historically cost a lot more than modified sine inverters.

Are modified sine wave inverters efficient?

Efficiency: They are relatively efficient but tend to have lower efficiency levels compared to pure sine wave inverters. Applicability: Modified sine wave inverters are suitable for some applications, including running basic household appliances, power tools, and lighting. 2.What is a pure sine wave inverter?

Is a pure sine wave inverter worth the extra cost?

For most users, a pure sine wave inverter is worth the extra cost for peace of mind, reliability, and device safety. Modified sine wave inverters still have their place, especially when cost is a concern or only basic power is needed. Learn the difference between pure sine wave and modified sine wave inverters.

What does a modified sine wave inverter look like?

A modified sine wave inverter produces an approximation of a real AC sine wave. If you chart it out, it looks like a sine wave at first, but if you look closely, there are jagged stair steps in the waveform as the inverter crudely flips between polarities rather than the smooth wave seen above.

Learn More

- Malaysia pure sine wave inverter sellers

- Universal pure sine wave inverter

- Pure sine wave inverter 13000W

- Democratic Republic of Congo Pure sine wave inverter for sale

- Muscat Pure Sine Wave Inverter

- 15000 watt pure sine wave inverter 60v72 universal

- Pure sine wave 5KW inverter

- Hanoi Industrial Frequency Pure Sine Wave Inverter

- Smallest 12v pure sine wave inverter

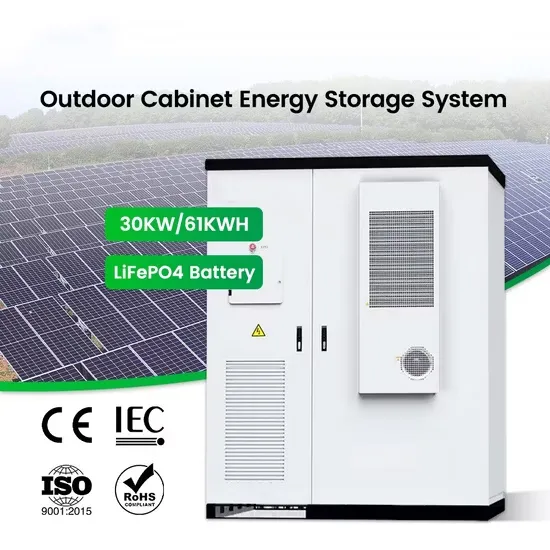

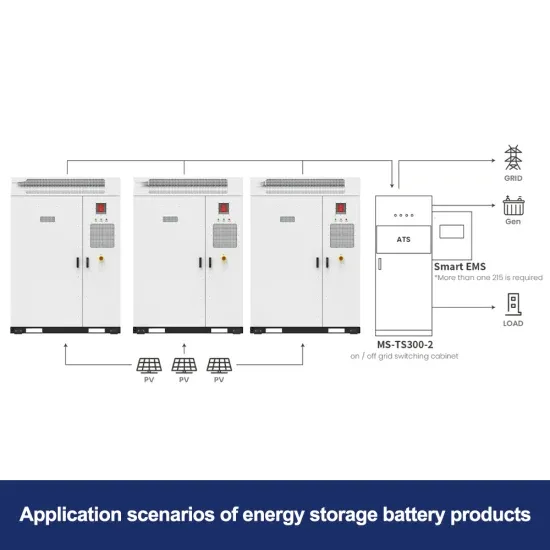

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.