What energy storage equipment does the factory use?

Aug 13, 2024 · The primary function of these systems is to store energy generated during low-demand periods or from renewable sources for later use when energy requirements peak.

What are the factory energy storage conditions? | NenPower

Aug 31, 2024 · Understanding factory energy storage conditions involves assessing crucial factors such as 1. Environmental parameters, 2. Storage medium selection, 3. Safety regulations, and

DS 5-33 Lithium-Ion Battery Energy Storage Systems

Sep 30, 2023 · This data sheet also describes location recommendations for portable (temporary) lithium-ion battery energy storage systems (LIB-ESS). Energy storage systems can be located

What are the factory power storage systems? | NenPower

Mar 10, 2024 · Factory power storage systems refer to a range of technologies designed to store electrical energy generated in manufacturing facilities for later use. These systems serve

What are the factory energy storage power supplies?

Jan 11, 2024 · Factory energy storage power supplies serve as vital components for industrial energy management. 1. They provide reliable power during peak demand periods, 2. Allow for

How much does factory energy storage cost? | NenPower

Apr 27, 2024 · UNDERSTANDING ENERGY STORAGE TECHNOLOGIES Energy storage is a critical component of modern electricity grids and factory operations. This segment focuses on

How about factory energy storage lithium battery | NenPower

Mar 28, 2024 · UNDERSTANDING FACTORY ENERGY STORAGE SYSTEMS Energy storage systems (ESS) utilizing lithium batteries play a critical role in modern industrial environments.

What procedures are required for factory energy storage?

Jun 17, 2024 · Energy audits serve to assess current consumption, identify inefficiencies, and delineate areas where energy storage can benefit. Various storage technologies include

HOW FACTORY ENERGY STORAGE SYSTEM WORKS

What is a battery energy storage system? Battery energy storage systems (BESS) are charged and discharged with electricity from the grid. Lithium-ion batteries are the dominant form of

Industrial Energy Storage: Powering Factories and Industries

Mar 30, 2025 · Industrial energy storage is essential for manufacturers. This article reviews various systems, such as lithium-ion batteries, flywheels, and thermal energy storage,

Battery Energy Storage Systems for Factories

Jul 4, 2025 · Energy storage systems are pivotal in helping factories harness the benefits of transitioning to renewable energy sources and adopting improved energy management practices.

What Does Factory Energy Storage Do? The Secret Sauce

That''s where factory energy storage swoops in like a superhero with a utility belt. These systems store electricity during off-peak hours (when rates are lower than a limbo champion) and

What Does Factory Energy Storage Do? The Secret Sauce

Let''s face it – factories suck up power like a toddler gulping juice boxes at a birthday party. That''s where factory energy storage swoops in like a superhero with a utility belt. These systems

How much does a factory energy storage system cost?

May 20, 2024 · In summary, the intricate landscape for factory energy storage systems encompasses a range of key factors such as technology type, costs associated with both

Energy Storage Factories: Powering the Renewable Revolution

Energy storage factories have emerged as the $33 billion answer to this global challenge [1]. These specialized facilities don''t just manufacture batteries; they create sophisticated systems

What are the factory energy storage air conditioners?

Sep 5, 2024 · Factory energy storage air conditioners are sophisticated systems designed to optimize energy usage in industrial settings. 1. They utilize thermal energy storage

6 FAQs about [What are the factory energy storage systems ]

What are energy storage systems?

Energy storage systems are devices capable of carrying out these transformations in an efficient and controlled way, allowing to better manage energy supply and demand nationwide. What is an energy storage system? An energy storage system is a device or set of devices that can store electrical energy and supply it when needed.

Why are energy storage systems important?

As the global energy demand grows and the push for renewable sources intensifies, energy storage systems (ESS) have become crucial in balancing supply and demand, enhancing energy security, and increasing the efficiency of power systems.

What is an electrical storage system?

Electrical storage systems are particularly well-suited to roles that demand rapid energy deployment. In the realm of power grids, they are used to perform tasks such as frequency regulation, which helps to maintain the balance between the grid’s supply and demand by quickly absorbing or releasing energy.

How does an energy storage system work?

An energy storage system consists of three main components: a control system, which manages the energy flow between the converter and the storage unit.

What are the different types of energy storage systems?

There are different types of energy storage systems, which differ in their technical characteristics, performance, costs and applications. The most widespread types include: batteries, which are electrochemical devices that store energy in the form of electrical charge.

What are the components of an energy storage system?

An energy storage system consists of three main components: a control system, which manages the energy flow between the converter and the storage unit. The operation of an energy storage system depends on the type of technology used, which can be chemical, electrochemical, mechanical, thermal, or electromagnetic in nature.

Learn More

- What are the capacitor energy storage systems in Libya

- What is the price of large energy storage cabinet factory in Nigeria

- What are the values of energy storage systems

- What are the hybrid energy storage systems

- What energy storage systems are there in Swiss office buildings

- What is the price of Ankara commercial energy storage cabinet factory

- What are the types of electric energy storage systems

- What qualifications are required for communication base station battery energy storage systems

- What energy storage battery is best for Brazil

Industrial & Commercial Energy Storage Market Growth

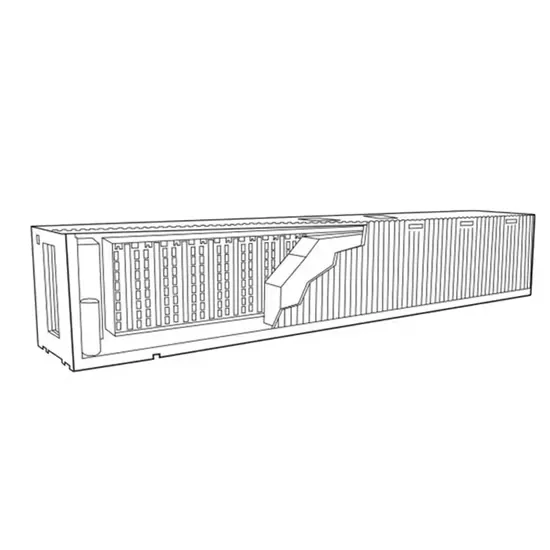

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.