What Is a Battery Rack Cabinet and How Does It Work?

Jun 14, 2025 · What Maintenance Practices Extend Battery Rack Cabinet Lifespan? Monthly inspections for corrosion, quarterly thermal imaging to detect hotspots, and annual load testing

Eaton Power Xpert 9395

Sep 7, 2024 · The 9395 battery cabinet is designed to use with the 9395, 9395P, and 9395C. The primary difference is the 9395C uses an Under Voltage Relay instead of a Shunt Trip device to

What Are Telecom Battery Cabinets and How Do They

Jul 10, 2025 · Telecom battery cabinets are specialized enclosures housing backup batteries that provide uninterrupted power to telecommunications infrastructure during outages. They ensure

Outdoor Battery Cabinets: The Impact of Regular Maintenance on Battery

Conclusion Regular maintenance of outdoor battery cabinets is essential for maximizing the efficiency and longevity of solar panel systems. By preventing battery degradation, ensuring

Essential ESTEL Maintenance Tips for Outdoor

Jun 11, 2025 · Protect your outdoor battery cabinet in extreme weather with tips on thermal management, waterproofing, cleaning, and structural reinforcement

Guide to Regular Maintenance of Battery Energy

Oct 22, 2024 · Regular maintenance is essential to ensure the safety, efficiency, and longevity of battery energy storage systems. This article will introduce the

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

How to Maintain Rack Battery Systems for Longevity?

Mar 19, 2025 · Rack battery systems require regular maintenance to ensure longevity. Key practices include monitoring voltage levels, cleaning terminals, balancing cells, and

The maintenance and care methods of lithium ion battery storage cabinet

Lithium ion battery storage cabinet requires regular maintenance to ensure its long-term stable operation. Specifically, the following steps need to be performed:

Microsoft Word

Nov 15, 2017 · The battery cabinet is equipped with narrow pallet jack or forklift access openings in the front and rear of the cabinet. Move the equipment into the desired location and set in place.

UPS Battery Room Maintenance and Precautions

Apr 10, 2025 · The core of Ups Battery Room maintenance lies in temperature control, moisture management, connection integrity, and proactive maintenance. Adopting precise

Operations Manual ZincFive BC Series UPS Battery

Jun 9, 2023 · ZincFive BC Series UPS Battery Cabinet Introduction The ZincFive BC Series UPS Battery Cabinet is comprised of ZincFive''s Nickel-Zinc Batteries integrated into a battery

BC58 Battery Cabinet Installation, Operation,

Connect main cables from the UPS or charger source to the battery cabinet output. The battery cabinet output connection point will vary depending on the cabinet configuration. The main

Cleaning and Maintaining the Battery Cabinet

Jun 13, 2025 · Ensure that the front of the battery cabinet is not obstructed. Ensure that the ventilation slots in the battery cabinet are unobstructed. Check the battery cabinet enclosure

Battery Maintenance for Equipment: 8 Tips for Maintaining

6 days ago · Regular inspection, cleaning of terminals/cables and adhering to the manufacturer''s recommendations are important steps in preserving battery life. Utilizing equipment-specific

BC55 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Eaton battery solutions brochure

Apr 3, 2025 · Three-phase UPS battery cabinets The IBC-SW cabinet is our newest and smallest battery cabinet of-fering, with one large string of batteries inside. This welded cabinet offers

Effective Maintenance for Outdoor Battery

Jun 11, 2025 · Maintain your outdoor battery storage cabinet with tips on cleaning, temperature control, and moisture prevention to ensure safety, durability, and

6 FAQs about [Battery cabinet maintenance]

How do you maintain a construction equipment battery?

Follow equipment-specific maintenance tips for construction equipment and electric vehicles, and utilize maintenance software to track and schedule tasks. Construction equipment batteries, including deep cycle batteries, may require additional maintenance due to harsh operating conditions.

What is a battery maintenance check?

Annual Check: In-depth assessment of battery health, analyzing performance, and predicting battery life. As a key component of modern energy solutions, battery energy storage systems require regular maintenance to ensure long-term stable operation and extend their lifespan.

How do you maintain a battery storage system?

Test air conditioning and fan equipment to ensure they are working well and maintaining stable battery temperature. Regularly clean the storage system's enclosure to prevent dust and moisture from entering. Ensure the enclosure's integrity by checking seals, locks, and other components for damage.

What types of batteries need maintenance?

Different types of batteries, such as lead-acid and lithium-ion, require specific maintenance techniques to ensure their longevity and performance. Knowing the type of battery you are working with is essential to guarantee the correct charging and maintenance techniques are employed.

Why is battery maintenance important?

Regular testing and inspection of batteries are crucial to ensure optimal performance and prevent potential issues. By being proactive with battery maintenance, you can minimize the risk of equipment malfunction and costly repairs. To ensure the best results, follow these maintenance tips.

How do I preserve my battery life?

Regular inspection, cleaning of terminals/cables and adhering to the manufacturer’s recommendations are important steps in preserving battery life. Utilizing equipment-specific maintenance tips and software can help maximize the efficiency of your equipment.

Learn More

- What are the components of the battery cabinet Site cabinet

- Costa Rica outdoor communication battery cabinet customized integrated system

- How many power strings are there in Jamaica s outdoor communication battery cabinet

- Battery cabinet original battery price

- Control Unit and Battery Cabinet

- Lithium Battery Site Cabinet Requirements

- Communication power supply supporting battery cabinet

- Tonga Battery New Energy Battery Cabinet

- What are the dimensions of the a3 battery cabinet

Industrial & Commercial Energy Storage Market Growth

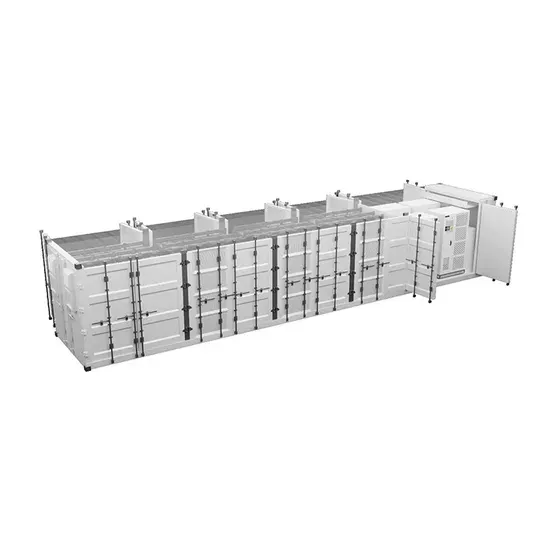

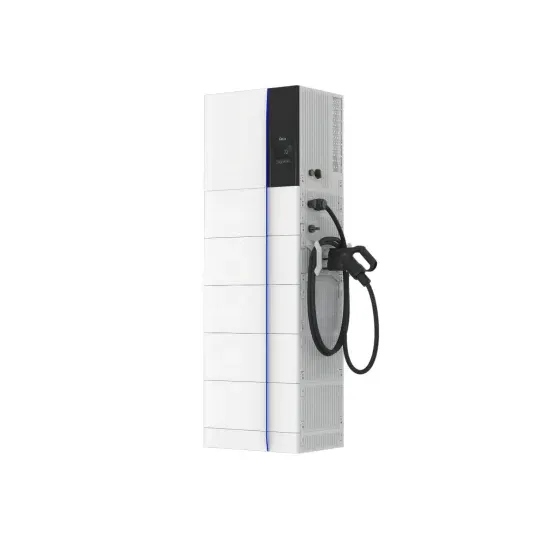

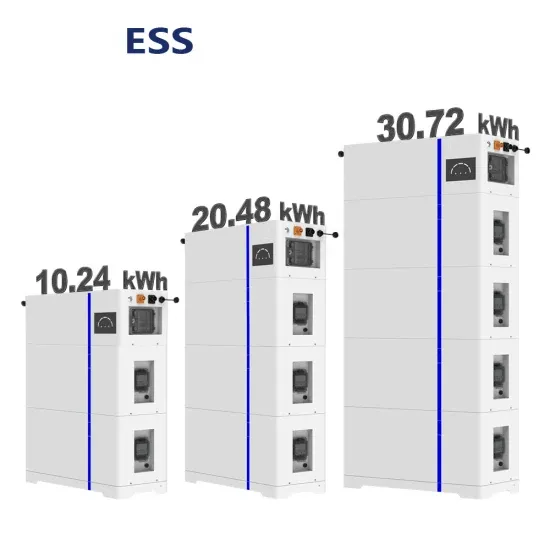

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.