Novel electrolyte rebalancing method for vanadium redox flow batteries

Aug 1, 2020 · Request PDF | Novel electrolyte rebalancing method for vanadium redox flow batteries | A new method is proposed that restores the battery energy and capacity of a

Assessing the levelized cost of vanadium redox flow batteries

Jun 1, 2020 · The vanadium redox flow battery (VRFB) has been one of the most widely researched and commercialized RFB systems because of its ability to recover lost capacity via

Mitigation of water and electrolyte imbalance in all-vanadium

Sep 10, 2021 · In all-vanadium redox flow battery (VRFB) systems, the electrolyte imbalance between the negative and positive electrodes inevitably occurs and subsequently necessitates

Restoring capacity and efficiency of vanadium redox flow battery

Jun 15, 2023 · Conclusion A new method for rebalancing a vanadium electrolyte is proposed, which consists of the partial posolyte reduction in an electrolysis cell with RuO 2 /Ti anode. CU

Electrochemical rebalancing process for vanadium flow batteries

Feb 1, 2023 · Among the different processes which have been proposed in the literature to rebalance the electrolyte and restore the VFB capacity, this paper consider the

All-Iron Hybrid Flow Batteries with In-Tank Rebalancing

May 30, 2019 · Development of sealed flow batteries with internal rebalancing is thus an important step toward the ideal "maintenance-free" operation. In this study, the criteria for stability in

System and process for rebalancing flow battery state of

Improvements to flow battery systems are described herein that maintain the state of charge of such batteries while maintaining osmotic pressure within the battery itself Flow batteries and

Rebalancing electrolytes in redox flow battery systems

Embodiments of redox flow battery rebalancing systems include a system for reacting an unbalanced flow battery electrolyte with a rebalance electrolyte in a first reaction cell. In some

Novel electrolyte rebalancing method for vanadium redox flow batteries

Feb 1, 2021 · A new method is proposed that restores the battery energy and capacity of a Vanadium Redox Flow Battery, by counteracting the charge imbalance caused by air-oxidation

Optimization of Electrolyte Rebalancing in Vanadium Redox Flow Batteries

Dec 20, 2021 · This paper presents a novel algorithm to optimize energy capacity restoration of vanadium redox flow batteries (VRFBs). VRFB technologies can have their lives prolonged

Hydrogen evolution mitigation in iron-chromium redox flow batteries

Jan 15, 2023 · For a battery with a symmetric chemistry, such crossover can be managed via rebalancing (remixing and recharging the electrolytes), an inexpensive, simple, and

SYSTEM AND PROCESS FOR REBALANCING FLOW BATTERY

1. A redox flow battery system, comprising: a redox flow battery apparatus comprising: a first tank comprising a negolyte solution, the negolyte comprising a quinone; a second tank comprising

Novel electrolyte rebalancing method for vanadium redox flow batteries

Feb 1, 2021 · A new method is proposed that restores the battery energy and capacity of a Vanadium Redox Flow Battery, by counteracting the charge imbalance caused

Novel electrolyte rebalancing method for vanadium redox flow batteries

Related papers A dynamic performance model for redox-flow batteries involving soluble species Frank Walsh Electrochimica Acta, 2008 A transient modelling framework for a vanadium redox

Electrochemical rebalancing process for vanadium flow batteries

Feb 1, 2023 · All-vanadium flow batteries (VFBs) may undergo electrolyte oxidation from atmospheric oxygen and/or hydrogen evolution because of operations at extrem

Method and system for rebalancing electrolytes in a redox flow battery

A method of rebalancing electrolytes in a redox flow battery system comprises directing hydrogen gas generated on the negative side of the redox flow battery system to a catalyst surface, and

Systems and methods for rebalancing redox flow battery

Mar 17, 2015 · Various methods of rebalancing electrolytes in a redox flow battery system include various systems using a catalyzed hydrogen rebalance cell configured to minimize the risk of

Rebalancing electrolytes in redox flow battery systems

Dec 23, 2014 · Embodiments of redox flow battery rebalancing systems include a system for reacting an unbalanced flow battery electrolyte with a rebalance electrolyte in a first reaction

Rebalancing/Regeneration of Vanadium Flow Batteries

Jan 6, 2023 · Rebalancing and regeneration are essential to counteract the evolution of electrolyte imbalance in flow batteries (FBs). These effects have different physical and

On Capacity Upgradation and In Situ Capacity

Aug 5, 2022 · Aqueous organic redox flow batteries (AORFBs) hold great promise in the storage of fluctuating renewable energy output for later use when there

Commercialization of All-Iron Redox Flow-Battery Systems

Jan 6, 2023 · Since 2011, ESS Tech, based in Wilsonville, Oregon, has innovated based on the concept of all-iron redox flow battery (IFB) and led the commercialization effort of IFB

State of charge monitoring methods for vanadium redox flow battery

Oct 15, 2011 · During operation of redox flow batteries, differential transfer of ions and electrolyte across the membrane and gassing side reactions during charging, can lead to an imbalance

Vanadium redox flow battery with slotted porous electrodes

Feb 15, 2019 · A 20-cell, 1 kW vanadium redox flow battery stack was assembled using thin bipolar plates and porous electrodes featuring interdigitated flow channels. Such a stack

6 FAQs about [Flow Battery Rebalancing]

Do sealed flow batteries have internal rebalancing?

In the case of sealed systems with internal rebalancing, the balance can be fully restored so that in principal, steady-state operation can be achieved. Development of sealed flow batteries with internal rebalancing is thus an important step toward the ideal "maintenance-free" operation.

How does rebalancing a battery work?

In a general view of the whole rebalancing process, it can be stated that the oxygen, which has caused the imbalance of the battery, has been removed by the rebalancing process and the chemical composition of the electrolyte has been restored. This is different in the case of imbalance by gassing of hydrogen: (36) 2 H + + 2 e - → H 2

How does electrolyte rebalancing work in vanadium redox flow batteries?

A novel electrolyte rebalancing method for vanadium redox flow batteries is presented. The method uses a rebalancing cell fed from the positive electrolyte tank. The rebalancing cell reduces the concentration of V (V) ions in the catholyte. A multi-physical numerical model is used to control and optimize the process.

Do hydrogen side-reactions cause electrolyte imbalance in all-iron flow batteries?

Conclusions Hydrogen side-reactions lead to an electrolyte imbalance in all-iron flow batteries, and this occurs simultaneously for iron and hydrogen species. Fortunately, this problem can be corrected using an appropriate rebalancing system.

How to restore imbalance in VRFB electrolytes by electrochemical regeneration?

A new method to restore the imbalance in VRFB electrolytes by electrochemical regeneration has been conceived and developed. The process is performed by using an electrolysis cell (called “regeneration cell”) where a positive electrolyte reduction is coupled with an oxygen evolution reaction catalyzed by a Ti-IrO 2 electrode.

How can a vanadium redox flow battery be regenerated?

A new method is proposed that restores the battery energy and capacity of a Vanadium Redox Flow Battery, by counteracting the charge imbalance caused by air-oxidation and hydrogen evolution in the negative electrolyte. The process makes use of a regeneration system specifically designed and successfully tested.

Learn More

- Communication base station flow battery detector

- N Djamena New Energy All-vanadium Liquid Flow Energy Storage Battery

- Is flow battery a new energy source

- Which type of flow battery is better

- Iron-based liquid flow battery energy storage system

- Africa s new all-vanadium liquid flow battery

- Flow battery skills and applications

- All-vanadium liquid flow battery device

- 50mw all-vanadium liquid flow battery energy storage power station

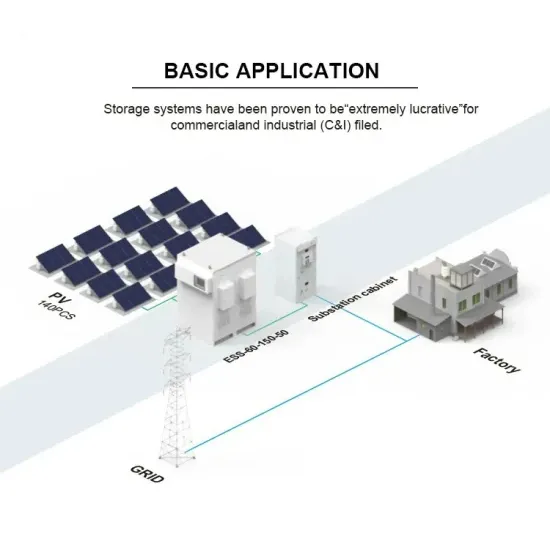

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.