Communication Base Station Voltage Regulation | HuiJue

Why Voltage Fluctuations Are Crippling Modern Telecom Networks Have you ever wondered why communication base stations experience 12% more downtime during monsoon seasons? As

Communication Base Station Energy Management | HuiJue

The $23 Billion Question: Can We Power Connectivity Without Burning the Planet? As global mobile data traffic approaches 1,000 exabytes monthly, communication base station energy

Where Grounding Bonds with Science Grounding Issues

Jan 18, 2023 · Grounding Issues for Utility Telecom As the practice of utilizing high voltage environments as locations for communications towers and switch sites becomes com

A framework for condition assessment of communication tower

May 1, 2025 · Assessing the condition of existing structures is a valuable approach to determining the extent of damage and formulating appropriate maintenance strategies. This article

Base station power supply maintenance-Network & Communication

Base station power supply maintenance: The development of mobile communications in my country over the past decade can be described as ultra-high speed, and the maintenance of

What Is Base Station in Mobile Communication? – The Heart

Jan 11, 2025 · Macro Base Stations Macro base stations are the traditional type of base stations used in mobile communication networks. They are typically installed in cell towers or rooftops

Life cycle cost of communication towers: identification and

Jul 1, 2025 · Communication towers are essential infrastructure in modern society, require effective life cycle cost (LCC) control for long-term sustainability.

Post-earthquake functional state assessment of communication base

Dec 1, 2024 · The application of this model provides support for the operation and maintenance of communication base stations, and insights for managing seismic risk and resilience of the

Electric field characteristics of shared towers and electric field

Dec 1, 2022 · Therefore, the "shared tower" with the function of a communication base station added to the existing high-voltage transmission line tower is becoming a new resource-sharing

Maintenance of communication base station power supply

This article discusses how to improve the power supply safety of the power supply system of communication base stations, reduce the failure rate of the power supply system of

Communication Base Station Maintenance Guide | HuiJue

Did you know a single communication base station failure can disrupt services for 5,000+ users? As global 5G deployments accelerate – with over 7 million base stations projected by 2025 –

Telecom Tower Maintenance Best Practices

Apr 7, 2024 · Telecom tower maintenance is crucial for ensuring uninterrupted communication services and the overall integrity of the tower infrastructure. Regular inspections and

Telecom Base Station Power System Solution

Basic requirements of communication network equipment for power system: 1.High reliability: Multiple backup design to ensure the continuous and stable operation of the system. 2.High

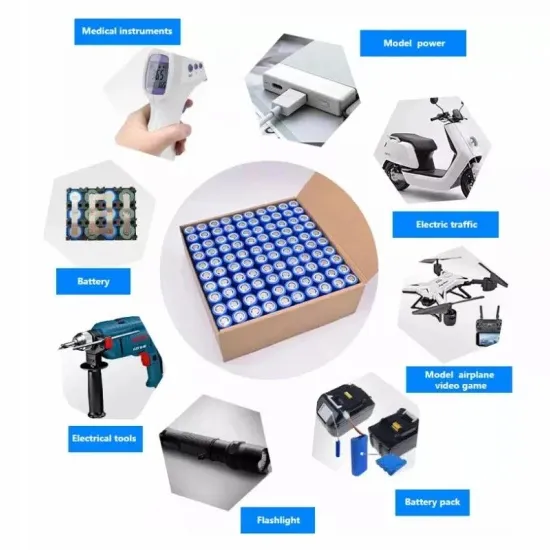

Communication Base Station Li-ion Battery Market

Quick Q&A Table of Contents Infograph Methodology Customized Research Key Drivers Accelerating Li-ion Battery Adoption in Communication Base Stations The transition to lithium

Electric field characteristics of shared towers and electric

Dec 2, 2023 · The electric field distribution near the tower with the base station, the electric field distribution characteristics under different base station installation quantities and different

Post-earthquake functional state assessment of communication base

Dec 1, 2024 · The reliability and resilience of communication base stations are critical to the post-earthquake performance of the communication system, and consequently influence the

Onboard Base Station: The Communication Hub of the

Mar 13, 2025 · The advent of onboard base stations aims to solve these problems. Acting as mobile communication fortresses, they provide crucial communication support in critical

基站建设与维护 (Base Station Construction and

Jul 14, 2025 · Job Description: A Base Station Construction and Maintenance Engineer is a professional who utilizes specialized tools to install, configure,

Design of Wireless Communication Base Station Monitoring

Jan 1, 2023 · With the rapid popularization of the network, under the increasingly complex network security situation and the increasingly prominent network security problems, network security

Low-Carbon Sustainable Development of 5G Base Stations in

May 4, 2024 · Goncalves et al. (2020) explored carbon neutrality evaluation of 5G base stations from the perspective of network structure and carbon sequestration. Despite the growing

Communication Base Station Availability: The Invisible

The Silent Crisis in Tower Infrastructure Using the PAS (Problem-Agitate-Solution) framework, let''s dissect the core issue: Current base station availability metrics hide critical vulnerabilities.

Optimal configuration of 5G base station energy storage

Feb 1, 2022 · The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize overall

6 FAQs about [Maintenance content of communication high voltage tower communication base station]

Why do telecommunication towers need maintenance?

Telecommunication towers transmit the signals that make fast, long-distance wireless communication possible. Regular maintenance of the structures can prevent many problems that cause essential components to fail.

How to maintain a telecom tower?

Common challenges include the need for frequent cleaning to remove debris and prevent signal interference. Best practices for tower maintenance include regular inspections, detailed record-keeping, predictive and preventive maintenance approaches, and cost-effective strategies. What Are the Requirements for Telecom Tower?

What are the components of a telecom tower?

Key components that enable the smooth operation of a telecom tower include various communications equipment, energy management assets, and supplementary power sources. These components play a crucial role in ensuring reliable and uninterrupted communication services. Communications equipment is at the heart of a telecom tower.

What are Telecom Tower maintenance best practices?

To minimize operational disruptions, telecom tower maintenance best practices include efficient monitoring through remote monitoring systems, standardized software configurations, and optimized energy usage.

How can preventive maintenance improve a tower's service life?

Implementing preventive maintenance strategies, such as regular inspections, repairs, and comprehensive record-keeping, can prevent equipment failures and extend the tower's service life.

What are the different types of Telecom Tower maintenance?

Different tower types, including lattice, guyed, monopole, camouflage, and mobile towers, have varied maintenance requirements. Implementing a preventive maintenance strategy through regular inspections and repairs helps prevent problems and component failures, ultimately extending the usable lifetime of telecom equipment.

Learn More

- Base station communication high voltage DC power supply

- Communication base station communication high voltage DC power supply

- Dubai base station communication tower 7MWh

- Communication tower and communication green base station

- The temperature of the battery energy storage system of the outdoor communication base station is too high

- Papua New Guinea communication base station wind power tower manufacturer customization

- Communication base station inverter signal tower migration

- Pakistan communication base station battery energy storage system tower manufacturer supply

- Communication base station flow battery tower has batteries

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.