Battery energy storage system (BESS) integration into power

4 days ago · Topic last reviewed: May 2025 Sectors: Downstream, Midstream, Upstream Overview Battery energy storage systems (BESS) use rechargeable battery technology,

Main grid grounding requirements for energy storage

The proposed hybrid charging station integrates solar power and battery energy storage to provide uninterrupted power for EVs, reducing reliance on fossil fuels and minimizing grid

Energy storage booster station substation

The station microgrid technology provides a flexible and efficient platform for the integration of distributed generation and renewable energy power generation technology and its application

Technologies and economics of electric energy storages in power

Nov 19, 2021 · However, the current use of EES technologies in power systems is significantly below the estimated capacity required for power decarbonization. This paper presents a

distance requirements between energy storage power station and substation

Review on key technologies and typical applications of multi-station integrated energy To realize the low-carbon development of power systems, digital transformation, and power

ENERGY STORAGE SYSTEMS FOR SINGAPORE

1 Executive Summary 1.1 Energy Storage Systems ("ESS") is a game-changing technology that potentially has significant benefits for Singapore. ESS''s unique characteristic is that it can

How to achieve energy storage in substation | NenPower

Apr 30, 2024 · As the energy landscape continues to evolve, the integration of advanced energy storage solutions in substations becomes increasingly essential to achieving a sustainable

Electrical Substations Explained: Key Functions

Sep 6, 2024 · The Definition and Purpose of Electrical Substations What is an Electrical Substation? An electrical substation is a key facility within the power

STANDARD DESIGN CRITERIA FOR ELECTRICAL

Jun 3, 2024 · By thoroughly understanding design inputs, this study establishes an example set of design criteria for high-voltage electrical substations. By explicitly stating the fundamental

How to Design a Grid-Connected Battery Energy

Oct 19, 2023 · Introduction A Battery Energy Storage System (BESS) significantly enhances power system flexibility, especially in the context of integrating

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Battery storage systems are emerging as one of the potential solutions to increase power system flexibility in the presence of variable energy resources, such as solar and wind,

Grid-Scale Battery Storage: Frequently Asked Questions

Jul 11, 2023 · What is grid-scale battery storage? Battery storage is a technology that enables power system operators and utilities to store energy for later use. A battery energy storage

Handbook on Battery Energy Storage System

Aug 13, 2020 · ACB = air circuit breaker, BESS = battery energy storage system, EIS = electric insulation switchgear, GIS = gas insulation switchgear, HSCB = high-speed circuit breaker, kV

Grid-Scale Battery Storage: Frequently Asked Questions

Jul 11, 2023 · A battery energy storage system (BESS) is an electrochemical device that charges (or collects energy) from the grid or a power plant and then discharges that energy at a later

Review on key technologies and typical applications of multi-station

Jun 1, 2022 · To realize the low-carbon development of power systems, digital transformation, and power marketization reform, the substation, data center, energy storage, photovoltaic, and

Energy management strategy of Battery Energy Storage Station

Sep 1, 2023 · New energy is intermittent and random [1], and at present, the vast majority of intermittent power supplies do not show inertia to the power grid, which will increase the

《电化学储能电站设计规范》GB51048-2014

May 30, 2025 · 中人民共和国国家标准 电化学储能电站设计规范 Design code for electrochemical energy storage station GB 51048-2014 主编部门:中国电力企业联合会 批准部门:中华人民共

Review of spatial layout planning methods for

Dec 4, 2024 · At present, the typical integration methods are "substation + energy storage power station + data center station + electric vehicle charging station

6 FAQs about [Energy storage power station substation requirements]

What are the requirements for electrical substation design?

Compliance with applicable standards is a fundamental requirement in the design of electrical substations. This ensures that the substation is designed and built to a level of quality and safety that is accepted internationally. Standards to be complied with may include those from IEC, IEEE, and national standards organizations.

What are standardized design criteria for high-voltage electrical substations?

To support this goal, a standardized design criteria for high-voltage electrical substations is proposed which outlines the key design inputs and considerations to ensure that the substation is designed to comply with requirements.

How do I integrate a Bess-connected substation to the power grid?

Integrating the BESS-connected substation to the power grid, it is necessary to understand the Grid codes. Although such requirements may vary in each country, the main requirements such as fault ride through, harmonic compliance, ramp rate regulation and frequency regulation are share a common principle.

How long can a substation battery last during a power outage?

During a power outage, the loads of the substation are supplied from the DC system batteries, so the batteries must be able to provide 24 hours of energy to enable functionality of the substation, even during a power outage. Substation IEDs shall conform to IEC 61850 standards for communication and integration.

Which kV substation should a 250 MW substation be connected to?

For connections with power capacity of 250 MW or more, the designated connection should be made to a 400 kV substation, if the connected power is less than 250 MW, the appropriate connection should be directed to either a 110 kV or 220 kV substation.

Does a substation need a Type D power plant?

The connection type was categorized as a type D power plant; thus, the substation must comply with the requirements set for type D power plant in the scope of the substation set by Fingrid in VJV2018. As previously discussed in chapter 3.10 , the requirements set for building electrification are explicitly stated in Table 25.

Learn More

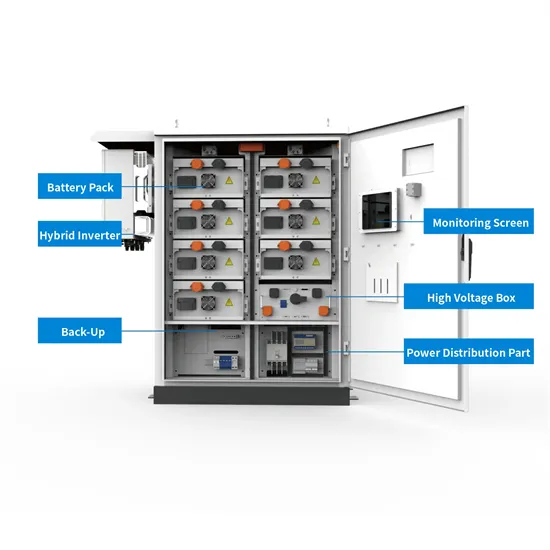

- Battery energy storage power station element

- Power station energy storage cabinet price trend

- Western Europe Energy Storage Power Station

- Kenya Mombasa Energy Storage Power Station Franchise Agent

- Photovoltaic power station energy storage and consumption

- Energy storage cabinet battery protection ESS power base station

- Base station lithium battery energy storage 30kw inverter power supply

- Riyadh Fort Energy Storage Power Station

- Does the energy storage battery in a solar power station have a big role to play

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.