Supply Chain Key to Delivery

Aug 16, 2024 · Supply Chain Key to Delivery Supply chain management is key to wind turbine supply. The relationships between manufacturers and their component suppliers have become

Hybrid Auxiliary Power Supply System for Offshore Wind Farm

Sep 28, 2018 · Diesel Generators (DG) are commonly adopted to supply the critical auxiliary loads for Offshore Wind Farm (OWF) during islanding operation. To reduce fuel consumption, avoid

wind solar complementary power supply system news

The system configuration of the communication base station wind solar complementary project includes wind turbines, solar modules, communication integrated control cabinets, battery

Boost Efficiency with Advanced outdoor wind turbine

About outdoor wind turbine suppliers outdoor wind turbine suppliers stand at the heart of clean power supply, turning moving air into useful electric current for business and home use. These

Integrating solar and wind energy into the electricity grid for

Jan 1, 2025 · This study aims to explore the concept of community grid support through solar and wind hybrid systems as a sustainable energy solution. Advantages of combining solar and

Sector supply-chain guidance – wind energy

Apr 30, 2025 · Sector supply-chain guidance – wind energy 1. Introduction This note focuses on actions a project sponsor or developer of a wind power project can take to help manage the

Off-Grid Wind Turbine Solutions for Reliable Remote Power Supply

Aug 8, 2025 · If you need power in remote or off-grid locations → Choose an off-grid wind turbine. Elege New Energy offers wind turbine solutions designed for farms, homes, islands, and

Global wind supply chain trends 2024 Report | Wood

Nov 21, 2024 · Wood Mackenzie''s Global wind turbine supply chain trends 2024 report deep dives into supply chain developments across key capital components like blades, gearboxes,

A review of hybrid renewable energy systems: Solar and wind

Dec 1, 2023 · Wind turbines (WT), the primary components of these systems, consist of blades that capture wind energy and spin a rotor connected to a generator, producing electrical power

Design of Off-Grid Wind-Solar Complementary Power

Feb 29, 2024 · According to the change of wind and solar radiation, the control module can realize three operation modes: wind generator supplying power to load independently, photovoltaic

DESIGN OF CHARGING SYSTEM USING HYBRID POWER

Apr 15, 2023 · *1,2,3,4,5,6Dept. Of Electrical And Electronics Engineering, Sanskrithi School Of Engineering, India. ABSTRACT People usually run out of phone and laptop charging while

6 FAQs about [Wind turbine plus outdoor power supply]

What is solar energy & wind power supply?

Solar energy and wind power supply are renewable, decentralised and intermittent electrical power supply methods that require energy storage. Integrating this renewable energy supply to the electrical power grid may reduce the demand for centralised production, making renewable energy systems more easily available to remote regions.

Can wind power supplement solar power generation by generating electricity?

When solar resources are scarce, wind power can supplement solar power generation by generating electricity. Solar power generation frequently coincides with periods of peak demand. This combination lessens the load on conventional power generation sources and aids in grid balancing . 2.1. Importance of renewable energy systems

Can solar power be combined with wind turbines?

For improved energy generation both during the day and at night, these facilities may combine solar PV with wind turbines or solar PV with concentrated solar power (CSP). For example, continuous energy generation can be achieved in areas with high solar insolation with hybrid CSP-solar PV systems [8, 9].

What are the benefits of solar energy & wind power?

By means of technology development, the combination of solar energy, wind power and energy storage solutions are under development . The solar and wind distributed generation systems have the benefits of the clean and renewable source of power supply.

What is solar & wind energy optimization?

The optimization process aims to balance the variability of solar and wind energy, ensuring a steady power supply by adjusting factors such as energy storage (batteries), generator capacity, and power conversion systems.

How to choose a good location for wind turbines & solar panels?

A good location for the installation of wind turbines and solar panels in the community is chosen. Elements like minimum shading, accessibility, and available land are accounted for. Based on the energy assessment, the required capacity of PV and wind power to meet the community's energy demand is calculated.

Learn More

- Outdoor wind and solar hybrid power supply system

- Outdoor power supply for wind farm

- Energy storage outdoor power supply plus solar energy

- Is there any outdoor power supply for sale in Bangkok

- Outdoor power supply with battery

- New EU outdoor power supply

- Energy storage cabinet solar portable outdoor mobile power supply

- Malta outdoor power supply for sale

- Bishkek local outdoor power supply

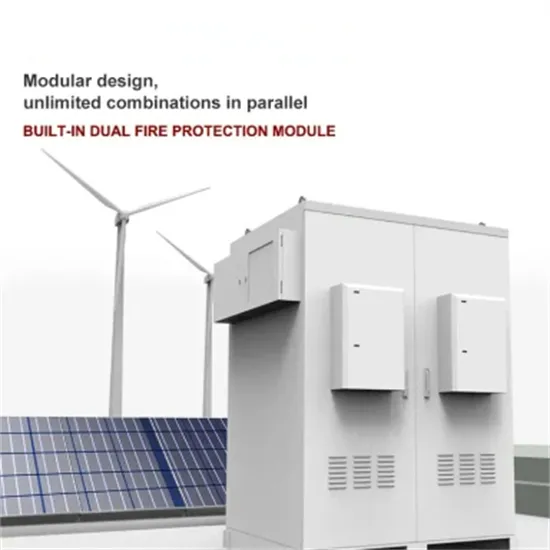

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.