Is a 48V Inverter Better Than a 12V or 24V System?

Feb 6, 2025 · Because a 48V inverter usually carries a lower current than a 12V or 24V system, the potential for power loss is often reduced, boosting overall efficiency. Potential Gains Of A

Choose 24v inverter or 48v inverter?-Residential Inverter

While both 24V and 48V inverters are commonly available, it''s worth checking the availability and compatibility of inverters with the rest of your system components, such as solar panels,

Tips to Choose the Right Inverter for Homes:

Sep 27, 2023 · Choose the Right Inverter with the difference between 12V or 24V and their advantages: inverter efficiency, battery bank setup, cabling cost, and

48V Inverter vs. 12V Inverter: Core Differences

Mar 19, 2025 · If you''re planning a power system, whether you choose a 48V or 12V inverter has a direct impact on efficiency, cost, and long-term reliability.

Is a 48V Inverter Better Than a 12V or 24V System?

Feb 6, 2025 · Figuring out which voltage is best can feel like a puzzle. In this article, we''ll dive into how a 48V inverter compares to 12V and 24V systems. We''ll look at how voltage impacts

48V vs 24V Advice Needed

Oct 4, 2021 · I''ve read other discussions on this and the consensus seems to be that 24V is acceptable but 48V is preferred. If you are going with inverters 3000 watts or higher than 48V

Can I Use A 24V Inverter On A 48V Battery? Compatibility

Feb 7, 2025 · No, you should not use a 24V inverter with a 48V battery. A 24V inverter is designed for 24 volts. Connecting it to a 48V battery can lead to overvoltage.

Inverter, Solar Inverter, Home Power Inverter | inverter

300 watt solar on grid inverter, grid tie inverter, pure sine wave output, converts 12V/24V DC to 120 AC, 48V DC to 230V AC is optional. Grid tie solar inverter with high performance MPPT

Is 48V more efficient than 24V?

Nov 28, 2023 · Voltage is a fundamental aspect of electrical systems, and choosing the right voltage level can have a significant impact on efficiency and performance. In recent years,

12V Inverter vs 24V Inverter — What Is The

Dec 11, 2024 · This article will explore the differences between 12v inverter vs 24v inverter, considering factors such as energy loss, battery requirements, and

Why Might You Need a Transformer or Converter When Using a 24V Inverter

Oct 28, 2024 · Using a 24V inverter with a 48V battery typically requires a transformer or converter to ensure compatibility. The inverter is designed for 24 volts, while the battery

What is the Difference Between a 12V, 24V, and 48V Inverter

Inverter batteries are essential components in off-grid and backup solar systems, providing stored energy for use when solar panels are not generating power. The voltage of the battery—12V,

12V vs 24V vs 48V – Which is Best for Your Solar

Aug 5, 2024 · The choice of voltage in a solar system—whether 12V, 24V, or 48V—is more than just a matter of preference; it''s a crucial decision that

48V vs 24V Advice Needed

Oct 4, 2021 · Alternatively, you may want to parallel multiple 24V inverters to reach the power levels of a 48V system. This is my 24V inverter, and it''s designed to run in parallel with a

Best All-in-One Off-Grid Solar Inverters for Reliable Energy

1 day ago · Verify the inverter supports your battery bank voltage (12V, 24V, 48V, etc.) and the type of batteries (lead-acid, LiFePO4 lithium) to ensure efficient charging and discharging.

Can I Use a 24V Inverter on a 48V Battery?

Dec 11, 2023 · No. Using a 24V inverter on a 48V battery is not recommended. The inverter is designed to operate at 24 volts, and connecting it to a 48V source can lead to overvoltage,

12V vs 24V vs 48V

Jun 16, 2025 · Confused about choosing between 12V, 24V, or 48V inverter systems? Discover which voltage is best for RV, solar, and off-grid setups. Learn the pros, cons, efficiency, cable

Differences Between 12V, 24V and 48V Inverter Systems

First, what''s the difference between 12V vs. 24V vs. 48V inverters? Most inverters will fall into three categories for their input requirements: 12VDC, 24VDC and 48VDC. This is referring to

6 FAQs about [48v inverter and 24v inverter]

What is a 48 volt inverter?

The 48v inverters require a 48-volt input voltage and are typically used in larger systems, such as residential and commercial solar installations or off-grid power systems. These inverters offer higher power output and improved efficiency, making them suitable for applications with significant energy demands.

Should I choose a 24V or 48V inverter system?

While 24v systems may offer immediate cost savings for small applications, 48v inverter systems provide better long-term value for larger or growing power requirements, due to their enhanced efficiency. Choosing between the 24v and the 48v inverters depends on factors such as your energy demands, efficiency and compatibility with other appliances.

Why is a 48V solar inverter important?

Higher voltages improve efficiency by reducing energy loss. A 48V inverter offers the highest efficiency, ensuring your solar system operates at peak performance, providing reliable and sustainable energy. The maintenance of your inverter is essential to ensure your solar system operates efficiently and lasts for years.

What is the difference between 24v and 48V?

This example clearly demonstrates that the 48V system transmits the same power with half the current compared to the 24V system. This not only minimizes resistive losses but also improves overall system performance.

What is a 48V power system?

a 48V configuration is deemed the most beneficial in terms of cost, space utilization, and overall system efficiency. 48V systems provide enhanced efficiency and are well-suited for handling the increased power load in larger residential installations and comercial/industrial systems.

Is a 12V or 24V inverter better?

As a result, asking if a 12V or 24V inverter is better becomes a question that cannot be answered. The reason being is each system has its own set of unique variables that makes it impossible to provide a single answer. Therefore, we find it is much more efficient to provide the answer to: Why would one choose a 12VDC, 24VDC or 48VDC power system?

Learn More

- Can a high frequency inverter 24v be converted to 48v

- 48v inverter and 24v inverter

- Inverter universal 24v

- What brand of 48v inverter is good in Bergen Norway

- 24v inverter 1000

- Choose 12v or 24v inverter

- Inverter 48v pure sine wave

- 48V to 220V 300W inverter price

- How much power can a 48v inverter achieve

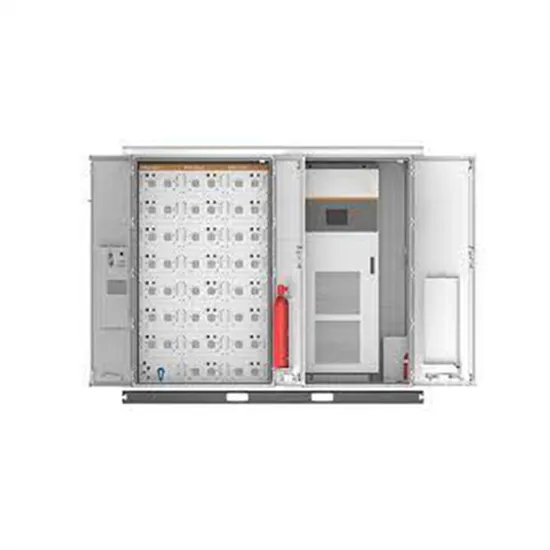

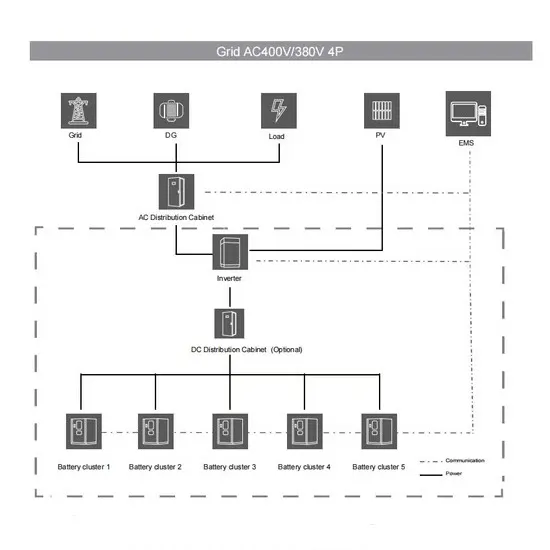

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.