Common specifications of energy storage cabinets

Battery energy storage system specifications should be based on technical specification as stated in the manufacturer documentation. Compare site energy generation (if applicable),and energy

Standard Specifications for Dimensions of Power

o Battery energy storage system specifications should be based on technical specification as stated in the manufacturer documentation. o Compare site energy generation (if applicable),

Safety technical specifications for energy storage cabinets

A framework is provided for evaluating issues in emerging electrochemical energy storage technologies. The report concludes with the identification of priorities for advancement of the

The latest coating specifications for battery energy

What does ul 9540a mean for battery energy storage systems? ire propagationin Battery Energy Storage Systems (BESS). UL 9540A was developed to address afety concerns identified in

Standard Specifications for Lithium Battery Energy

AZE''''s 42U indoor battery rack cabinets painted with polyester powder, suitable for different brands lithium-ion batteries, it is the perfect solution for housing your Low Voltage Energy

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Common specifications of energy storage cabinets

Oct 15, 2024 · An energy storage cabinet, sometimes referred to as a battery cabinet, plays a critical role in the safe and efficient operation of energy storage systems, particularly those

The latest coating specifications for battery energy

Apr 18, 2021 · The new Vertiv HPL Lithium-ion battery cabinet is available today in North America in 38 kWhcabinets. The successful completion of the UL 9540A test and its associated

The latest technical specifications for lithium battery

Battery energy storage system specifications should be based on technical specification as stated in the manufacturer documentation. Compare site energy generation (if applicable),and energy

Design specifications and standards for household

Compare site energy generation (if applicable),and energy usage patterns to show the impact of the battery energy storage system on customer energy usage. The impact may include but is

What are the ventilation requirements for energy

Lithium battery energy storage cabinets can meet the needs of different large-scale projects and are very suitable for grid auxiliary services and industrial and commercial

BATTERY CABINETS CATALOGUE

Jun 4, 2025 · The cabinets covered by the technical specification have been designed to contain the hermetic lead-acid electric accumulator batteries. The construction characteristics of the

What are the battery cabinets in the energy storage

What are battery cabinets used for? ications,electric power,transportation,and other industries. In recent years,with the popularization of renewable energy,battery cabinets ha e become an

The latest design specifications for liquid-cooled energy

What is a liquid cooled energy storage system? It''s the latest liquid cooled energy storage system featuring a compact and optimized design, enabling more profitability, flexibility, and safety.

Technical Specifications for Energy Storage Outdoor Cabinets

• Battery energy storage system specifications should be based on technical specification as stated in the manufacturer documentation. • Compare site energy generation (if applicable),

Design Specifications for Square Battery Energy Storage Cabinets

Today, we''re cracking open the design playbook to explore how these square battery energy storage cabinets balance safety, efficiency, and pure engineering geniu

List of applicable standards for energy storage cabinets

Far-reaching standard for energy storage safety,setting out a safety analysis approach to assess H&S risks and enable determination of separation distances,ventilation requirements and fire

What Are the Key Benefits of Battery Energy Storage Cabinets?

Jul 4, 2025 · Understanding Battery Energy Storage Cabinets In today''s rapidly advancing energy landscape, Battery Energy Storage Cabinets are emerging as a key component in our

6 FAQs about [What are the specifications of new energy battery cabinets ]

Which accumulator batteries are included in the cabinets covered by the technical specification?

The cabinets covered by the technical specification have been designed to contain the hermetic lead-acid electric accumulator batteries.

How many MWh can a 20 ft battery storage system produce?

The DC sides of the battery clusters are connected in parallel and then connected to the DC side of the PCS. The energy of a single cabin can reach more than 5MWh. Compared with the mainstream 20-foot 3.72MWh energy storage system, the 20-foot 5MWh energy storage system has a 35% increase in system energy.

How much energy does a 280ah battery cabin use?

A 20-foot liquid-cooled battery cabin using 280Ah battery cells is installed. Each battery cabin is equipped with 8 to 10 battery clusters. The energy of a single cabin is about 3MWh-3.7MWh. You can click our liquid cooling vs air cooling to get more information about cooling.

How many batteries do you need for a 5 MWh storage container?

According to calculations, a 20-foot 5MWh liquid-cooled energy storage container using 314Ah batteries requires more than 5,000 batteries, which is 1,200 fewer batteries than a 20-foot 3.44MWh liquid-cooled energy storage container using 280Ah energy storage batteries.

Where can I find the instruction manual for the batteries?

Inside the door there is a document pocket containing the instruction manual for the batteries. The sections can be fixed together to form a single cabinet. Where required, the cabinet is completed by a special compartment or switch/disconnector cubicle containing the protection equipment.

How does a 5MWh+ battery cabin work?

According to industry experts, most of the 5MWh+ battery cabins adopt centralized topology and liquid cooling and heat management. There are 12 battery clusters in the whole cabin. The DC sides of the battery clusters are connected in parallel and then connected to the DC side of the PCS. The energy of a single cabin can reach more than 5MWh.

Learn More

- What are the portable mobile energy storage battery cabinets

- Companies in Cameroon that collect new energy battery cabinets

- What are the heat dissipation methods of new energy storage cabinets

- New Energy Batteries and Battery Cabinets

- What are the types of energy storage battery specifications

- Why do new energy battery cabinets charge evenly

- What products are energy storage battery cabinets used for

- What is the energy storage battery company in Sri Lanka

- What is a dynamic energy storage battery

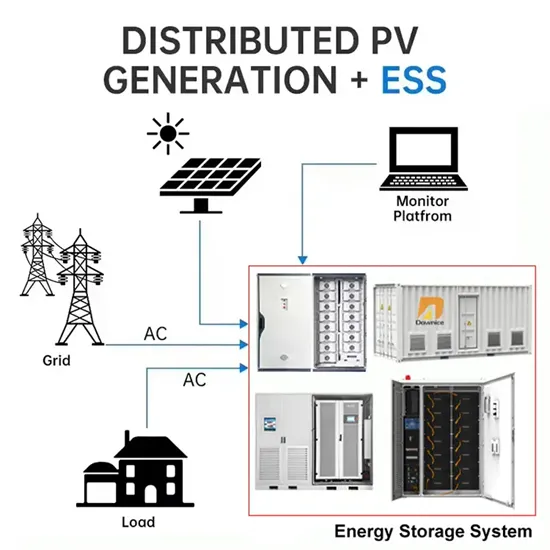

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.