Work starts on Australia-first battery factory

Sep 24, 2024 · Iron flow batteries store large-scale solar and wind power and provide that electricity for up to 14 hours to power stations, energy retailers

eLumina unveils $20M factory to drive Qld''s EV

Oct 29, 2024 · eLumina has officially opened Australia''s first factory capable of producing both community lithium batteries and electric vehicle (EV) chargers,

Tesla battery on fire at Bouldercombe energy

Sep 26, 2023 · Witnesses have reported loud bangs, "multicoloured" flames and a plastic smell after a Tesla battery caught fire at one of Queensland''s first

$20 million community battery and EV charger factory opens

Oct 30, 2024 · eLumina has opened Australia''s first factory that can produce both community lithium batteries and EV chargers, with the first model set to come off the production line in

Battery start-up opens ''Australian first'' factory

Oct 30, 2024 · Elumina has officially opened a manufacturing and development centre in Queensland''s southeast that it says will be the first in Australia

Experts warn fires caused by lithium batteries set

Sep 27, 2023 · Fires caused by lithium batteries are expected to increase over the coming years as use of the highly flammable product continues to rise, an

Lithium Portable Power Station | Lithium Portable Power Station

The Ardent Lithium Power Station is a portable lithium power hub that can keep your electronic gear running for hours—or even days—at a time. Lightweight and portable, the Ardent lithium

Queensland 200MW Chinchilla Battery starts commercial

Aug 12, 2024 · 200MW Chinchilla Battery enters commercial operation in Queensland The Chinchilla Battery is the first of three CS Energy projects to contribute to Queensland''s 80%

First-of-its-kind eLumina factory opens on Gold

Oct 29, 2024 · A first-of-its-kind battery factory has officially been opened by eLumina on the Gold Coast, with its first model set to come off the production

eLumina: Australia''s First Lithium Battery Manufacturer

Oct 30, 2024 · eLumina has officially opened its state-of-the-art manufacturing facility on the Gold Coast, marking Australia''s first factory equipped to produce both community lithium batteries

$20 million community battery and EV charger factory opens

Oct 30, 2024 · eLumina has opened Australia''s first factory that can produce both community lithium batteries and EV chargers, with the first model set to come off the production line in 2025.

Stanwell to test and make Redflow long duration

Jul 2, 2024 · Stanwell partners with Redflow to trial large-scale zinc bromine flow technology and lay foundations for a battery manufacturing plant in Queensland.

Fire at Genex Power battery project in Qld a ''rare

Sep 27, 2023 · Genex Power chief executive Craig Francis says too early to tell cause of fire at 50-megawatt Bouldercombe battery project near Rockhampton.

6 FAQs about [Lithium power station factory in Brisbane]

Where is Australia's first community battery factory?

Based on the Gold Coast, 75 km south of Brisbane, the 2,500 square metre factory is Australia’s first community battery manufacturing facility and is set up to produce 300 lithium battery EV chargers a year.

Will lithium Australia build a battery supply chain in Australia?

“The MOU between Lithium Australia and Centrex highlights our commitment to building a battery supply chain domestically in Australia, which can provide global battery manufacturers an alternative supply source for LFP and LMFP,” Lithium Australia managing director and chief executive officer Simon Linge said.

Who is building Queensland's biggest battery?

Premier Steven Miles, Deputy Premier Cameron Dick and Energy Minister Mick de Brenni have today marked the start of construction on one of Queensland’s biggest batteries. In a partnership with Tesla and Yurika, Queensland’s publicly owned CleanCo will deliver the $330 million battery in Swanbank.

Could lithium Australia get a phosphoric acid supply deal?

Lithium Australia and Centrex offshoot, Agriflex, are in talks for a potential phosphoric acid supply deal from Agriflex’s Ardmore phosphate rock mine in Queensland.

What happened to Australia's first grid-scale battery plant?

Last year Brisbane-based iron flow battery manufacturer Energy Storage Industries secured $65 million from the state Labor government to build Australia’s first manufacturing plant for grid-scale batteries, but flow battery company Redflow was put into administration.

Who is delivering the $330 million battery in Swanbank?

In a partnership with Tesla and Yurika, Queensland’s publicly owned CleanCo will deliver the $330 million battery in Swanbank. Set to be a pivotal component for the Swanbank Clean Energy Hub and Queensland’s clean energy future, the Swanbank Battery will be constructed on the site of the former Swanbank B coal-fired power station.

Learn More

- Lithium power station factory in Portugal

- China lithium power station factory Buyer

- High quality lithium battery power station Factory

- Lithium power station factory in Ecuador

- Lithium power station factory in Austria

- High quality portable power station europe Factory

- 1000 wh power station factory in Slovakia

- Camping power station factory in Sydney

- Outdoor power station factory in Croatia

Industrial & Commercial Energy Storage Market Growth

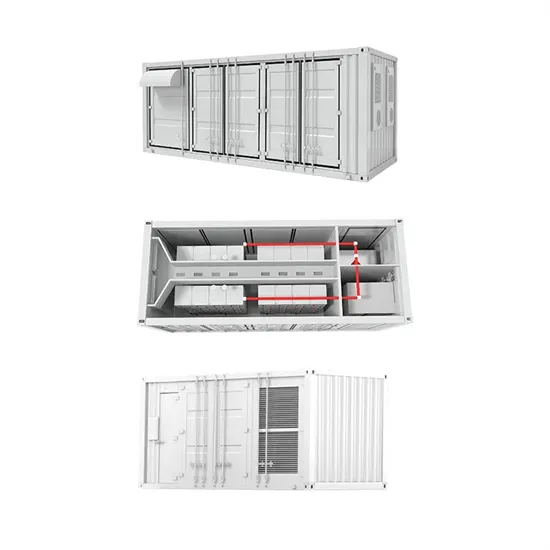

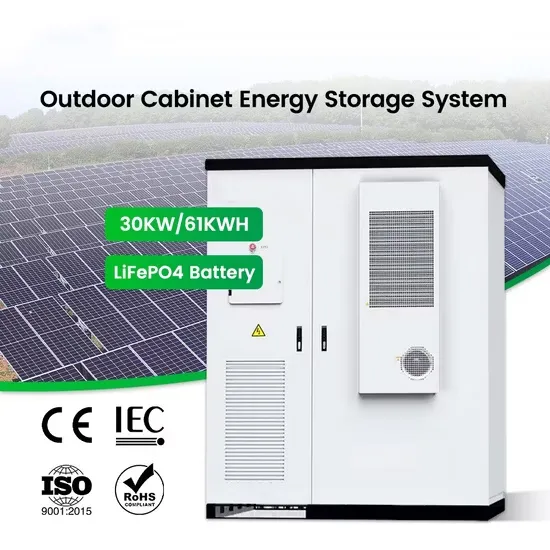

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

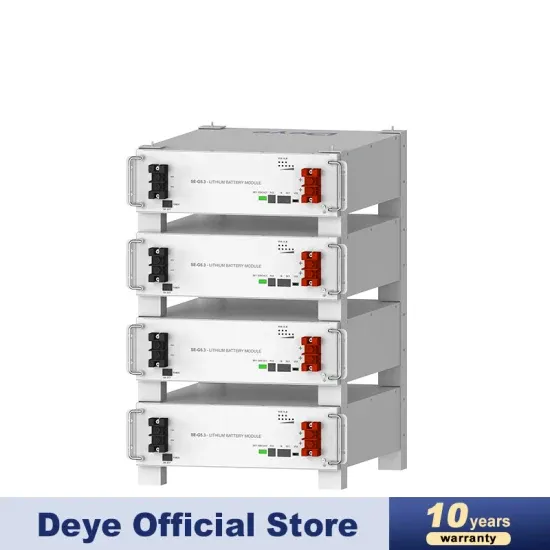

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.