Power supply method of outdoor power supply

The invention discloses a power supply method of an outdoor power supply, which comprises the following steps: charging the battery pack by using a solar cell panel or an oil engine; when the

Outdoor energy storage power supply structure layout

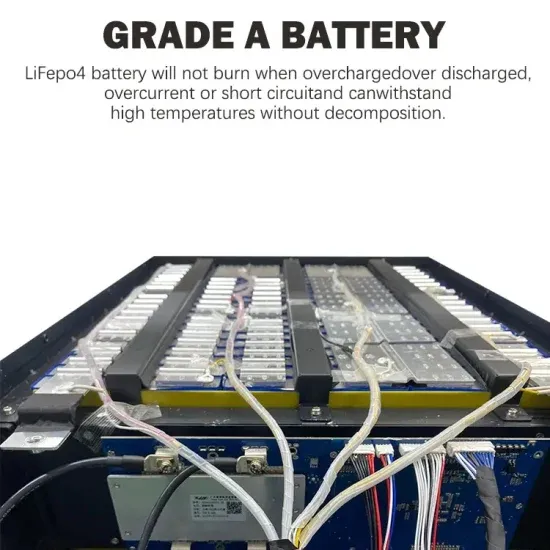

Portable intelligent outdoor power supply 1000W, 1 set of equipment to meet the needs of multiple sets of charging, equipped with automobile A-class battery cells, more stable performance,

Outdoor Power-supply System | NTT Technical Review

NTT''s communication centers and wireless base stations are equipped with backup power supplies to maintain communication services even in the event of a power failure. These

Weatherproof outdoor dc power supply, DC waterproof power supply

The protection rating IP65 means Huijue Outdoor Compact Integrated DC Power Module and Battery Module is a weatherproof outdoor DC power supply. It is reliable, powering network

China Customized Outdoors Mobile Power Supply

The outdoor power supply is an outdoor multifunctional power supply with a built-in lithium-ion battery and its own electric energy storage, also known as a portable AC or DC power supply.

Outdoor Communication Energy Cabinet | Moblie, Hybird Power

Experience the HJ-SG-D02 series from Huijue Group, a versatile outdoor communication energy cabinet designed for stable power supply in communication base stations, smart

Solar energy and communication battery cabinets

Bete is one of the best battery cabinet manufacturing integrators in China, and we are committed to providing communications physical connectivity equipment products, technologies and

Outdoor power supply and battery backup unit Ceraun 1 and 2

4 days ago · The Ceraun 1 and Ceraun 2 outdoor power supply and battery backup units provide reliable PoE (power over Ethernet) power for Tropos outdoor mesh routers, wired clients and

How To Solve The Power Supply Problem Of Communication

Nov 12, 2024 · Solution for Power Supply and Energy Storage of Solar Communication Base Stations With the continuous extension of communication network construction to remote

Research on Application of Power Line Communication in

Oct 13, 2024 · To build an intelligent battery management system (BMS), transmitting signals from a smart battery is an unavoidable and imminent issue. Power line communicatio.

Communication network cabinet lithium battery outdoor

High quality Lithium Battery IP55 Outdoor Integreted Power Cabinet With PDU UPS Monitoring System from China, China''''s leading power supply cabinet product, with strict quality control

How Can A Smart BMS Enhance Your Outdoor

Jul 8, 2025 · Whether it''s camping, picnicking, or other outdoor activities, portable power BMS ensures that the battery safely and efficiently powers various devices

Communication for battery energy storage systems

Dec 1, 2018 · By storing energy during periods of high power production and supplying it to the grid when power production is low, a battery makes it possible to meet a power injection

6 FAQs about [Battery communication for outdoor power supply]

Can a Bess be used with a battery energy storage system?

Measurements of battery energy storage system in conjunction with the PV system. Even though a few additions have to be made, the standard IEC 61850 is suited for use with a BESS. Since they restrict neither operation nor communication with the battery, these modifications can be implemented in compliance with the standard.

What are the components of a battery system?

The system consists of three components: a control center, a PV system and a BESS. Depending on the PV system’s output and supply forecast, the control center prompts the change of the incoming and charging power at the battery by transmitting the SetData and SetValues services.

What is the purpose of a power supply interface?

This interface can also be used to activate actions to control frequency, active power and voltage . The standard is also used for protective equipment. Exchanging data in real time ensures that electrical components at risk are disconnected from a grid when overloaded .

What are the logical nodes of the battery system zbat & zbtc?

The logical nodes of the battery system ZBAT and the battery charger ZBTC are responsible for battery data. The node ZBAT contains general information on the battery, including battery type, capacity and charging (power injection). They can also be used to perform logical node tests and to switch the system on and off.

What is IEC 61850 for battery energy storage systems?

IEC 61850 for battery energy storage systems Use of standard IEC 61850 has steadily evolved in recent years and other standard documents have been published, which specify information exchange between other components in the electrical grid.

How does the control center communicate with the PV system?

The control center communicates with the PV system by a Modbus protocol and with the BESS by IEC 61850. The IEC 61850 data structures provided by the BESS were created beforehand by a configuration file. Fig. 5 presents a schematic of this structure. Fig. 5. use case “meeting the supply forecast”. 5.1. Constraints on implementation

Learn More

- Battery outdoor power supply low power

- Outdoor communication power supply BESS platform price

- Backup lithium battery power supply for communication base stations

- 12v battery assembly outdoor power supply

- How many power strings are there in Jamaica s outdoor communication battery cabinet

- Tokyo communication base station battery energy storage system hybrid power supply

- Lead-acid battery power supply for communication base stations

- North Macedonia has outdoor communication power supply BESS

- Outdoor power supply with self-assembled battery

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.