A Simple Guide to Energy Storage Power Station Operation and Maintenance

Sep 3, 2024 · Exencell, as a leader in the high-end energy storage battery market, has always been committed to providing clean and green energy to our global partners, continuously

Construction of digital operation and maintenance

In order to cope with the limited power generation caused by the annual increase of new energy installed capacity and insufficient power supply channel capacity, the power plant adopts the

Best Practices for Operation and Maintenance of

Aug 19, 2025 · National Renewable Energy Laboratory, Sandia National Laboratory, SunSpec Alliance, and the SunShot National Laboratory Multiyear Partnership (SuNLaMP) PV O&M

Operation and Maintenance of PV Systems: Data

Nov 30, 2023 · NOTICE This work was authored in part by the National Renewable Energy Laboratory, operated by Alliance for Sustainable Energy, LLC, for the U.S. Department of

Photovoltaic energy storage station operation and

The operation of microgrids, i.e., energy systems composed of distributed energy generation, local loads and energy storage capacity, is challenged by the variability of intermittent energy

IEEE Draft Guide for Design, Operation, and Maintenance of

May 1, 2019 · This standard applies to: (1) Stationary battery energy storage system (BESS) and 1 mobile BESS. (2) Carrier of BESS, mainly includes but not limited to lead acid battery, lithium

IEEE Guide for Design, Operation, and Maintenance of Battery Energy

Application of this standard includes: (1) Stationary battery energy storage system (BESS) and mobile BESS; (2) Carrier of BESS, including but not limited to lead acid battery, lithiumion

Construction of digital operation and maintenance

Abstract. In view of the current increasing new energy installed capacity and the frustration in outputting clean electricity due to limited channel capacity, the new energy intelligence

Maintenance of energy storage power stations

In order to solve the problems in big data analysis of maintenance of large-scale battery energy storage stations, an intelligent operation and maintenance platform has been designed and

Solar Operations and Maintenance Resources for

4 days ago · After solar energy arrays are installed, they must undergo operations and maintenance (O&M) to function properly and meet energy production

Best Practices for Operation and Maintenance of

Apr 26, 2019 · Best Practices for Operation and Maintenance of Photovoltaic and Energy Storage Systems; 3rd Edition. Golden, CO: National Renewable Energy Laboratory. NREL/TP-7A40

Energy Storage Product Operation and Maintenance: The

Mar 5, 2023 · While solar panels and wind turbines steal the spotlight, it''s the energy storage product operation and maintenance teams that keep the lights on when the sun isn''t shining or

Technologies for Energy Storage Power Stations Safety Operation

Feb 26, 2024 · As large-scale lithium-ion battery energy storage power facilities are built, the issues of safety operations become more complex. The existing difficulties revolve around

IEEE Guide for Design, Operation, and Maintenance of

Jun 16, 2023 · IEEE SA Standards Board Abstract: Application of this standard includes: (1) Stationary battery energy storage system (BESS) and mobile BESS; (2) Carrier of BESS,

New Best-Practices Guide for Photovoltaic System

May 24, 2017 · The guide encourages high-quality PV system deployment and operation that improves lifetime project performance and energy production. Optimizing and standardizing

Development and application of a digital twin model for Net zero energy

Feb 1, 2025 · Net Zero Energy Buildings (NZEB) represent a significant opportunity to reduce building energy consumption and achieve the climate and energy goals that will be necessary

Exploration of Key Technologies for Equipment Operation and Maintenance

Nov 1, 2023 · The article proposed a long-term maintenance research method for the key technologies of equipment O&M in the new PS, achieving precise management and efficient

Intelligent operation and maintenance of energy storage

In recent years, energy storage systems have rapidly transformed and evolved because of the pressing need to create more resilient energy infrastructures and to keep energy costs at low

storage & grids O&M in storage

May 21, 2024 · Operations and maintenance, in the sense we would apply the term as a service industry segment of solar, simply does not exist for battery storage systems. Third-party

6 FAQs about [Energy Storage and New Energy Operation and Maintenance]

Do energy storage products need periodic maintenance?

The requirements for periodic maintenance for energy storage products should be identified by the OEM (IEEE 2010). In settings where predictive analytics maintenance is economical, guidance should also be available from the manufacturer that identifies methodologies for assessing when a product may be approaching a failure mode.

What should NREL consider when testing energy storage systems?

Photo by Owen Roberts, NREL Considerations for energy storage system testing include the following. If cost-justified by a large purchase, consider qualification testing of battery systems. Include test conditions in specifications for battery O&M diagnostics and testing.

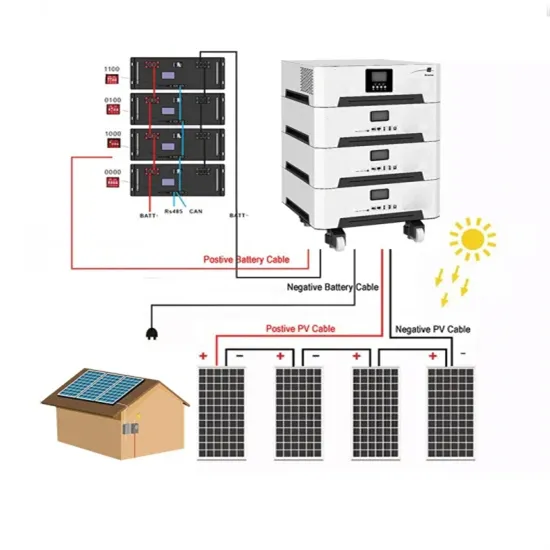

What is a combined generation and storage system?

These combined generation and storage systems can be “islanded” in remote or isolated areas or grid-tied with the ability to operate both with interaction with the grid or disconnect from the grid to maintain operations separately as needed (e.g., in the event of a grid outage).

Is stationary energy storage safe?

There are many codes and standards relating to safety of stationary energy storage at the local, national, and international levels by UL, NFPA (NEC, 70E), ANSI, CSA, and IEC, among others.

What is a resilient energy system?

Resiliency: Defined as applications that seek to provide extended energy services during system outages. An example is a home system that is outfitted with a separate critical loads panel that allows the combination of rooftop PV and storage to power critical loads for a period of time.

Can energy management strategies cope with MGS equipped with ESS?

Contrary to other proposed approaches, the present work aims at defining an energy management strategy that is able to cope with the main issues of MGs equipped with ESS, i.e., ESS degradation and unexpected outages of the main grid, which can be appreciated only considering long time horizons.

Learn More

- New energy storage power station operation model

- What are the operation and maintenance equipment of energy storage stations

- Energy storage operation and maintenance costs

- Overseas Energy Storage Operation and Maintenance Solutions

- Juba New Energy Lithium Battery Energy Storage Industrial Park

- New energy storage cabinet factory opens in Bissau

- How many liquid cooling energy storage manufacturers are there in New Zealand

- New Zealand energy storage battery manufacturer

- What are the energy storage intelligent operation and inspection systems

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.