energy storage power station foundation construction quotation

Research on the application of energy consumption monitoring technology in the construction of pumped storage power station Pumped storage power station plays an important role in

Energy Storage Container Foundation Construction: Best

Meta Description: Discover proven energy storage container foundation construction templates to prevent structural failures. Learn about site preparation, frost heave prevention, and modular

Energy Storage EPC Quotation: What You Need to Know

Jul 26, 2022 · Let''s face it: getting an accurate energy storage EPC quotation can feel like trying to solve a Rubik''s Cube blindfolded. Between technical jargon, fluctuating material costs, and

Design quotation of container energy storage power

What is containerized energy storage? ABB''s containerized energy storage solution is a complete,self-contained battery solution for a large-scale marine energy storage. The batteries

I-beam foundation of energy storage container

The main objectives of this paper are to seek for an optimized structure of direct/indirect energy storage container in the M-TES system, and to study the structure-performance relationship

mozambique container energy storage system quotation

Containerized Energy Storage System Complete battery storage systems scale marine energy storage. The batteries and all control, interface, and auxiliary equipment are deliv - ered in a

Energy storage container power station construction

Feb 16, 2021 · By interacting with our online customer service, you''ll gain a deep understanding of the various Energy storage container power station construction specifications featured in our

Design Specifications for Energy Storage Container

Design Specifications for Energy Storage Container Foundation Pit What is pit thermal energy storage (PTEs)? Pit thermal energy storage (PTES) is one of the most promising and

price quotation of iraq energy storage container power station

Technologies for Energy Storage Power Stations Safety As large-scale lithium-ion battery energy storage power facilities are built, the issues of safety operations become more

Container Energy Storage Construction: Building the Power

Imagine a shipping container that could power a small town - that''s exactly what container energy storage construction is making possible. These steel boxes are being transformed into

Energy Storage Container Foundation Construction: Best

Why Proper Foundations Matter for Energy Storage Containers You know, over 23% of battery storage system failures in 2023 were traced back to inadequate foundations according to a

Construction cost of container energy storage base

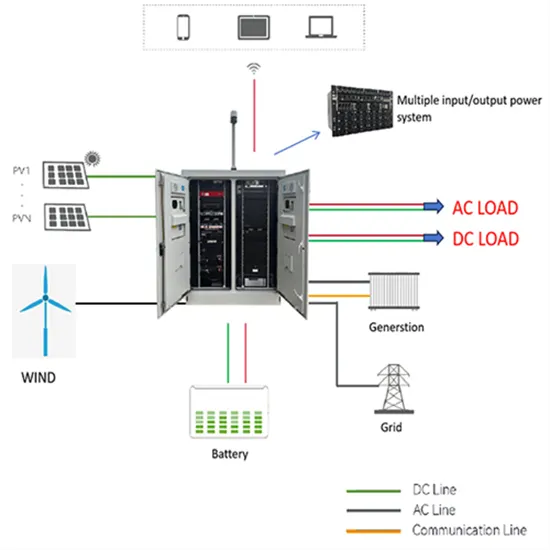

Taking the 1MW/1MWh containerized energy storage system as an example, the system generally consists of energy storage battery system, monitoring system, battery management

Photovoltaic energy storage container foundation construction

Photovoltaic energy storage container foundation construction plan design. The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design

Foundation design of container energy storage power

What is a containerized battery energy storage system? Containerized Battery Energy Storage Systems (BESS) are essentially large batteries housed within storage containers. These

Construction cost of container energy storage system

The 2020 Cost and Performance Assessment provided installed costs for six energy storage technologies: lithium-ion (Li-ion) batteries, lead-acid batteries, vanadium redox flow batteries,

Energy storage container power station quotation

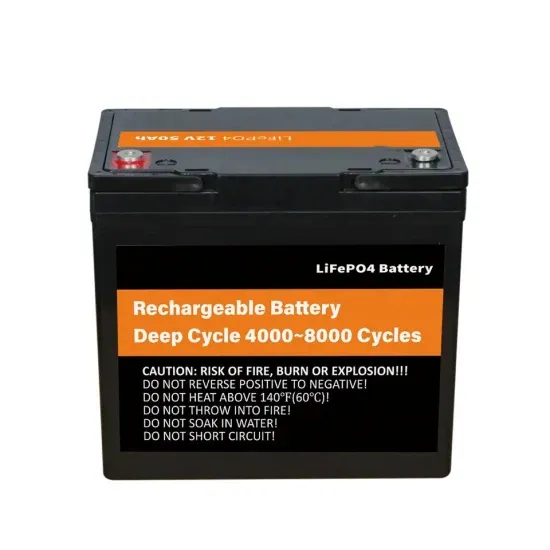

Container energy storage power station adopts domestic first-line brand battery design, cycle life of up to 8000 times, integrated power system, BMS system, temperature control system,

Energy storage container construction tutorial

What is Container Energy Storage? Container energy storage, also commonly referred to as containerized energy storage or container battery storage, is an innovative solution designed

The BESS System: Construction, Commissioning, and O&M

4 days ago · The Industrial and Commercial (C&I) Energy Storage: Construction, Commissioning, and O&M Guide provides a detailed overview of the processes involved in building,

Energy Storage Container Foundation Construction Price Key

Summary: Understanding energy storage container foundation construction prices is critical for renewable energy projects. This article explores cost drivers, design considerations, and

Sales of energy storage containers in poland

The containers are sold at Balticon branches located throughout Poland. We offer all types of containers. We offer see and refrigerated containers in standard sizes - 6 and 12 metres (20

Middle East MW energy storage container quotation

According to CES''''s "Energy Transformation Outlook for the Middle East and North Africa", it is expected that by 2030, the MENA region will deploy 40-50GWh of energy storage projects,

Energy Storage EPC Quotation: What You Need to Know

Jul 26, 2022 · But here''s the good news—this guide will untangle the complexities and help you navigate the world of EPC (Engineering, Procurement, and Construction) pricing like a pro.

5MWh Liquid Cooling Container with (2P52S Module)

Jul 11, 2025 · 2. Introduction of the BESS Container The 5MWh Liquid Cooling Battery Energy Storage System (BESS) Container is an integrated system with high energy density,

How to Calculate Construction Cost of Energy Storage Station Foundation

Building a robust foundation for energy storage systems is critical for safety and efficiency. This guide breaks down the key factors, formulas, and industry insights to estimate costs for lithium

Battery Enclosure: Carrying Platform and Safety for Energy Storage

Aug 1, 2025 · In the construction of an energy storage system (ESS), the cells, the battery management system (BMS), the safety design and the electrical topology are undoubtedly the

5 FAQs about [Construction quotation of container energy storage foundation]

How to install a containerized energy storage system?

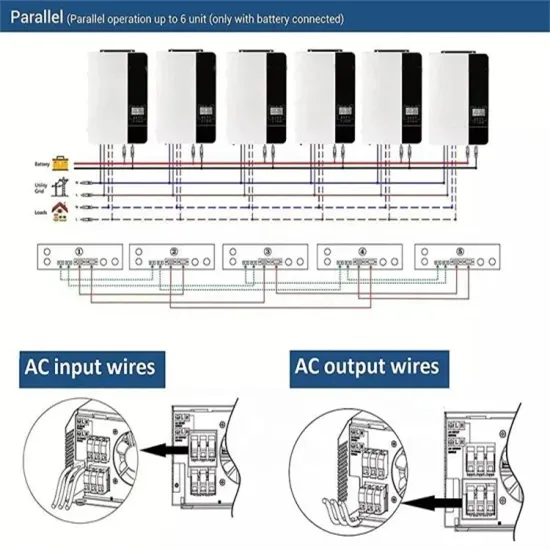

Use an insulating heat-shrinkable tube for secure terminal fit and label wires clearly. Clean up any foreign objects in the distribution cabinet. Connect all metal shells within the energy storage box to form a grounding network using good conductors or dedicated grounding strips. 6. Containerized Energy Storage System Installation Complete

What are the sections of energy storage project guide?

The guide is divided into three main sections: construction and installation, commissioning, and operation & maintenance. It covers various aspects such as foundation construction, battery and inverter installation, wiring, system testing, monitoring, fault handling, and preventive maintenance. 1. Energy Storage Project Construction 2.

What is C&I energy storage?

The Industrial and Commercial (C&I) Energy Storage: Construction, Commissioning, and O&M Guide provides a detailed overview of the processes involved in building, commissioning, and maintaining energy storage systems for industrial and commercial applications.

What are the steps in energy storage installation?

The main steps are: to build the foundation, install the energy storage cabinets, install the battery and inverter, and wire it all. During the commissioning of an energy storage system, which tests does the team perform? System-wide joint commissioning.

What is energy storage platform & how does it work?

The platform connects global energy storage projects for intelligent O&M. It allows monitoring of project operations and battery performance. The platform gathers data to maximize its value, aiding in optimizing designs and extending service life.

Learn More

- 40-foot outdoor energy storage container foundation design

- Energy storage container fire protection system construction

- Energy storage container fire protection project construction plan

- Construction quotation of battery energy storage system for communication base station

- Minsk energy storage container production enterprise

- Bloemfontein energy storage container liquid cooling system solution

- Container energy storage cabinet supplier ranking

- When will container energy storage cabinets be available

- Export declaration of container energy storage system

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

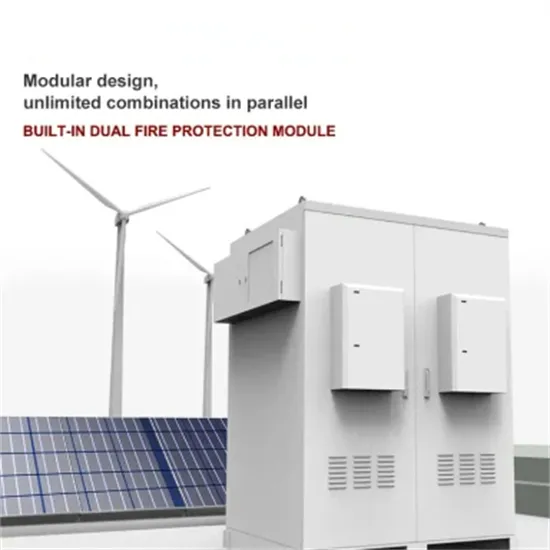

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.