Components of photovoltaic system: Elements

Jul 9, 2024 · Inverter: the core component of the PV system Photovoltaic inverter converts the direct current produced by the panels into alternating current,

Solar photovoltaic power plant diagram with explanation pdf

With proper planning and implementation, solar PV power plants have the potential to revolutionize the way we generate and consume electricity. In conclusion, the diagram of a

Fundamentals and performance of solar photovoltaic systems

Jan 1, 2021 · The inverter is an essential component in most PV systems to convert the direct current (DC) PV output into an alternating current (AC) one, allowing the use of AC-powered

How Solar Inverters Work for Solar Panels

Feb 28, 2014 · In this article we discuss how inverters work, includ-ing string, or single-phase, and central, 3-phase inverters; explore major inverter functions, key components, designs,

Overview of power inverter topologies and control structures

Feb 1, 2014 · This paper gives an overview of power inverter topologies and control structures for grid connected photovoltaic systems. In the first section, various configurations for grid

HANDBOOK ON DESIGN, OPERATION AND

May 29, 2024 · This Handbook covers "General Practice" and "Best Practice" associated with solar PV system installation and maintenance. "General Practice" refers to general

A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · The use of solar PV is growing exponentially due to its clean, pollution-free, abundant, and inexhaustible nature. In grid-connected PV systems, significant attention is

Chapter 1: Introduction to Solar Photovoltaics – Solar

Create a basic design plan for a residential solar photovoltaic system, considering factors like location, orientation, and system size. c. Compare the advantages and disadvantages of fixed

TECHNICAL SPECIFICATIONS OF ON-GRID SOLAR PV

Feb 3, 2021 · 3. Definition electronics, which feeds generated AC power to the Grid. Other than PV Modules and Inverter/Inverters, the system consists of Module Mounting Structures,

RENEWABLE ENERGY TECHNOLOGIES-----

Oct 20, 2024 · nverter for a specific solar PV system. The following are the main types of PV inverters classified by power level: Inverter according to power level: mainly divided into

An Introduction to Inverters for Photovoltaic

Jun 3, 2020 · An Introduction to Inverters for Photovoltaic (PV) Applications This article introduces the architecture and types of inverters used in photovoltaic

6 FAQs about [Basic structure of photovoltaic panel inverter]

What are the different types of inverters used in PV applications?

Based on power processing stage, the inverter may be classified as single stage and multiple stage inverters. This paper presents a comprehensive review of various inverter topologies and control structure employed in PV applications with associated merits and demerits.

What is a photovoltaic inverter?

This person is not on ResearchGate, or hasn't claimed this research yet. The inverter is an integral component of the power conditioning unit of a photovoltaic power system and employs various dc/ac converter topologies and control structure. It has to meet various international standards before it can be put in commercial use.

How many input channels does a PV inverter have?

The input section of the inverter is represented by the DC side where the strings from the PV plant connect. The number of input channels depends on the inverter model and its power, but even if this choice is important in the plant design, it does not affect the inverter operation.

How to pair a solar inverter with a PV plant?

In order to couple a solar inverter with a PV plant, it’s important to check that a few parameters match among them. Once the photovoltaic string is designed, it’s possible to calculate the maximum open-circuit voltage (Voc,MAX) on the DC side (according to the IEC standard).

How a PV inverter is controlled by an energy management system?

The PV inverter will and optimally controlled by an energy management system. As the PV system has a highly may be connected. The emerged configurations are designated as central inverter, string inverter, multistring inverter, and ac cell/module. These configurations are shown in Figs. 1共a兲 and 1共b兲.

What is the control structure of an inverter?

The inverter is controlled by two minimum time feedback loops. IV. CONTROL STRUCTURE and is shown in Fig. 13. The overall control structure of Fig. 13 can be distinctly divided control, and 共 iv 兲 grid side control. and to provide a sinusoidal current reference. The overall PLL structure is assigned the task of

Learn More

- Photovoltaic panel lighting tile inverter

- Outdoor photovoltaic panel structure and price

- India Mumbai DC panel inverter structure

- Photovoltaic inverter cost structure

- MF photovoltaic panel inverter

- Photovoltaic panel inverter accessories

- 660 photovoltaic panel inverter

- Photovoltaic panel inverter system design

- Inverter in photovoltaic power station

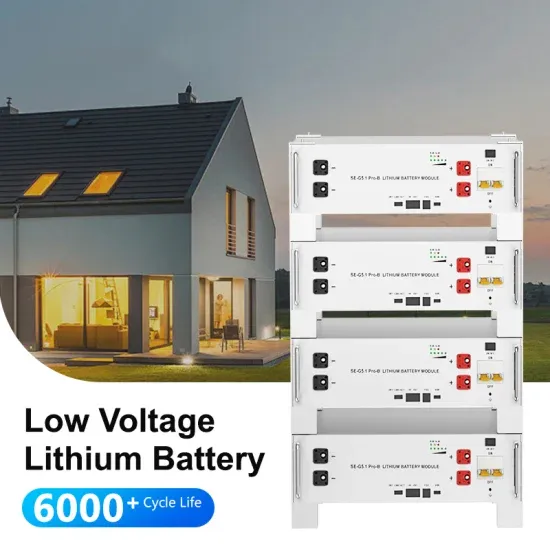

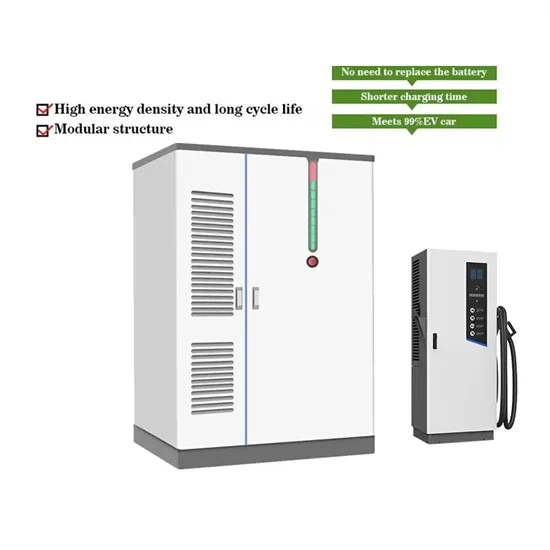

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.