Streamlined Port Logistics: Efficient Container Freight Station Design

May 22, 2024 · Design an efficient Container Freight Station (CFS) to streamline container handling logistics and enhance operational workflow. Analyse potential site, create 2D layout

Shipping Container Cafe Design & Construction:

Jan 7, 2025 · Transform a shipping container into a thriving container cafe with this comprehensive design and construction guide. So if you''re planning a

The Container Store hiring Outside Sales & Design

The Outside Sales & Design Consultant is a highly skilled salesperson with a proven track record of results and provides exceptional service in premium custom designs and organizational

Container Freight Station: Process & Operations Explained

Apr 7, 2025 · Discover the essential functions of a Container Freight Station (CFS) and how they streamline global trade operations through services like storage, consolidation, customs

Stochastic modeling of unloading and loading operations at a container

May 1, 2018 · The quay cranes position the containers at the quayside buffer locations. ALVs transfer the containers from the quayside to a prespecified stack block. After reaching the

Optimal Design of Container Terminal Layout

Jun 5, 2024 · The design of the container terminal includes strategic design choices such as the terminal layout at the stackside, choice of equipment for handling containers at the seaside

Fundamentals of Modern Electrical Substations

Mar 16, 2023 · Part 1 of this course series is concentrated on demonstrating how modern power systems are arranged to accomplish all these goals; what place electrical substations have in

How to Plan & Execute the Best Container

Oct 10, 2022 · How to Plan & Execute the Best Container Freight Station Project? A freight station is a place where goods can be unloaded and loaded onto

Rule-based dynamic container stacking to optimize yard operations

Jan 1, 2021 · The paper introduces a Rule-Based Dynamic Container Stacking (RBDCS) model which contains a three-step methodology. The developed RBDCS model determines yard

Petro-Box Mobile Fuel Stations Portable Fuel Containers Stations

Jan 28, 2024 · Petro-Box Mobile Fuel Stations Portable Fuel Containers Stations for Diesel, Find Details and Price about Gas Station Equipment Portable Gas Station from Petro-Box Mobile

Microsoft Word

Feb 17, 2023 · 12.2.1 Seaside cranes (so-called STS cranes) are used for (un)loading operations of containers onto(from) vessels. A first step in the design process of a terminal is to determine

What is a Container Freight Station (CFS)? | Interwf

Aug 18, 2025 · In CFS shipping, the station acts as a hub where shipments are efficiently managed, stored, and prepared for international transportation. A

Foundations for Shipping Containers: 4 Types

4 days ago · Explore the different types of foundations for shipping containers ⏩ Learn the best foundation types and designs to ensure stability and longevity

The Configuration of Container Yards | Port

Aug 19, 2025 · The Configuration of Container Yards There are several methods to store and stack containers in a container yard, which is in its simplest form

6 FAQs about [Container company base station design position]

How to design a container terminal?

Several of the larger ones will be automated. The design of the container terminal includes strategic design choices such as the terminal layout at the stackside, choice of equipment for handling containers at the seaside and landside, and type of vehicles for container transport between seaside and the landside.

Do new container terminal layouts need a smaller footprint?

New layouts require smaller footprint and must ensure faster, cheaper, and more efficient transfer of containers between the landside and seaside. This paper first reviews the literature on the transition of terminal layout designs from traditional to automated and future container terminals.

Why is container terminal design important?

Container terminal design plays a crucial role in the global logistics landscape. A well-optimized terminal layout can significantly enhance cargo handling efficiency, ultimately leading to faster turnaround times and reduced operational costs.

Are diagonal yard layouts effective for container terminal design?

The diagonal layouts have been adopted as the conceptual design of future container terminals (Zaerpour et al. 2019; Gharehgozli et al. 2020), however, few existing studies make in-depth analysis on the efficiency and application challenges of diagonal yard layouts.

What are the tradeoffs between container terminal layouts and traditional layouts?

To answer this ques - those designs that would guarantee sufficient storage and throughput capacity. container terminal layouts, two main tradeoffs need to be considered. Reg arding with the high footprint costs (e.g., for land reclamation) of traditional la youts. high costs of labor in traditional layouts. In such comparisons, the higher rev -

What is container terminal yard layout?

ections.12.3 Container Terminal Yard LayoutsIn this section the yard layout problem is discussed. The storage yard layout is de-fined by the organization of the driving lanes, by the number of driving lanes, y the orientation of the storage blocks, the block structure, and the design of the storage b

Learn More

- Egypt photovoltaic base station container installation

- Battery installation container for communication base station

- Distribution cabinet warehouse container base station

- Small distribution cabinet container base station

- Telecom lead-acid battery container base station

- Communication base station battery energy storage system cabinet company

- Belmopan Telecommunication Base Station Lead Acid Battery Power Generation Company

- Design of Capital Energy Storage Container Power Station

- Berlin container communication base station photovoltaic site energy

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

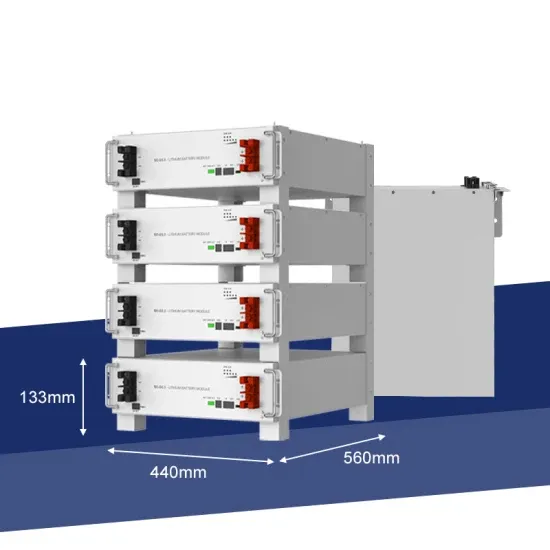

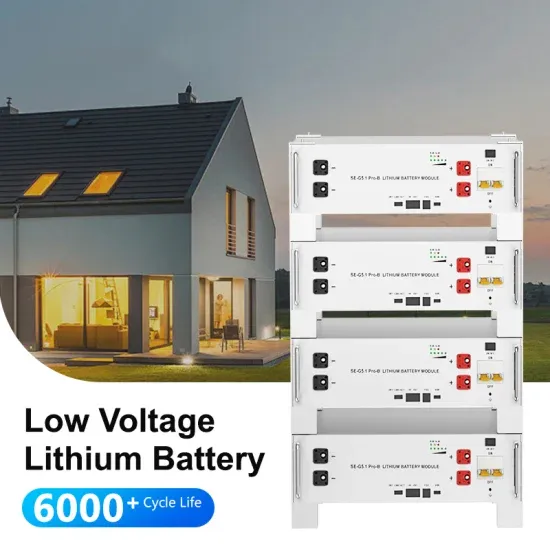

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.