Analysis of Cylindrical Lithium Battery Advantages and

1. Definition of cylindrical lithium battery Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery. The structure of a typical

Battery production systems made in Europe

Feb 19, 2025 · Schuler passed an important milestone as a supplier for gigafactories with the construction of a formation line for a large German battery cell manufacturer. After the planned

Lyten''s Nevada Gigafactory Is a $1B Vote of

Oct 16, 2024 · Lyten''s Nevada Battery Gigafactory Is a $1B Vote of Confidence in Lithium-Sulfur Facility to manufacture cathode materials, lithium anodes, and

About BSLBATT | Lithium Battery Manufacturer

5 days ago · As the world''s leading Lithium Battery Manufacturer & Supplier, we provide high-quality LiFePO4 batteries for many fields and cooperate with the

Where is the Amsterdam lithium battery new energy factory

As the best lithium battery manufacturer & supplier with 15 years of experiences, Huahui New Energy currently has five battery systems, including lithium titanate battery, lithium iron

Nearly 10 battery companies built factories in Southeast Asia

Sep 12, 2023 · In October last year, the company announced that it would invest in cylindrical lithium battery manufacturing projects in Malaysia, with an investment amount of no more than

''World''s first'' lithium-sulfur battery gigafactory

Oct 25, 2024 · The hydrogen is converted into clean fuel while the carbon builds Lyten 3D Graphene, used in the production of the company''s lithium-sulfur

Nevada is getting the world''s first lithium-sulfur battery

Dec 11, 2024 · Supermaterials trailblazer Lyten will invest over $1 billion to build the world''s first lithium-sulfur battery gigafactory in Reno, Nevada. The new factory will be capable of

Japan''s Panasonic Energy to commence mass production for

Sep 10, 2024 · Leveraging its 30 years of know-how in the development of cylindrical lithium-ion battery technology, Panasonic Energy has pioneered a mass production method for high

LG Energy Solution''s $5.5 Billion Stand-Alone

Apr 4, 2024 · The cylindrical battery plant, called LG Energy Solution Arizona, will produce 46-Series batteries for electric vehicles (EV). A crucial part of the

Battery production systems made in Europe

Feb 19, 2025 · These advantages relate to important safety aspects (unlike lithium-ion batteries, solid-state batteries cannot catch fire); they have higher energy density than lithium-ion

The Handbook of Lithium-Ion

Aug 16, 2025 · Figure 1 Parallel hybrid configuration 24 Figure 2 Series hybrid configuration 24 Figure 3 Operating cycle of hybrid car 25 Figure 4 States that have enacted ZEV emissions

World''s first gigafactory for litihum-sulfur batteries planned

Oct 16, 2024 · Lyten''s factory will manufacture cathode active materials (CAM) and lithium metal anodes and complete assembly of lithium-sulfur battery cells in both cylindrical and pouch

4 FAQs about [Amsterdam cylindrical lithium battery factory]

Who is Lithium Werks?

Lithium Werks provides cells, custom battery packs, and battery management systems into markets such as stationary energy storage, industrial, commercial marine, and transportation. Using patented technology, Lithium Werks focuses on long-term partnerships with our clients to provide powerful, inherently safe and reliable battery systems.

Where will stellantis produce LFP batteries?

The facility will produce LFP batteries for Stellantis in Spain. Production is expected to start by the end of 2026 and have an annual capacity of up to 50 GWh. Stellantis and CATL will invest up to €4.1 billion, or around $4.25 billion, to build the large-scale European LFP battery plant.

How many EV battery plants does CATL have in Europe?

CATL already has two EV battery plants in Europe, one in Germany and the other in Hungary. Last month, it announced its third through a new partnership with Jeep maker Stellantis. The facility will produce LFP batteries for Stellantis in Spain. Production is expected to start by the end of 2026 and have an annual capacity of up to 50 GWh.

Which EV battery company dominates the global EV market?

CATL is already dominating the global EV battery market. According to SNE Research, CATL accounted for 36.8% of the market through November 2024. Despite more competition, CATL is still growing. Through November 2023, CATL accounted for 36.2% of the market. China’s BYD was second, with a 17.1% share, up from 15.9% the previous year.

Learn More

- Cook Islands cylindrical lithium battery factory

- Minsk cylindrical lithium battery customization factory

- Best lithium battery power station Factory

- Magadan lithium battery cylindrical and square

- Cylindrical lithium battery recommendation

- What is a dual-cell cylindrical lithium battery

- Tunisian cylindrical lithium battery

- Syria cylindrical lithium iron phosphate battery

- Lithium battery pack factory in Arequipa Peru

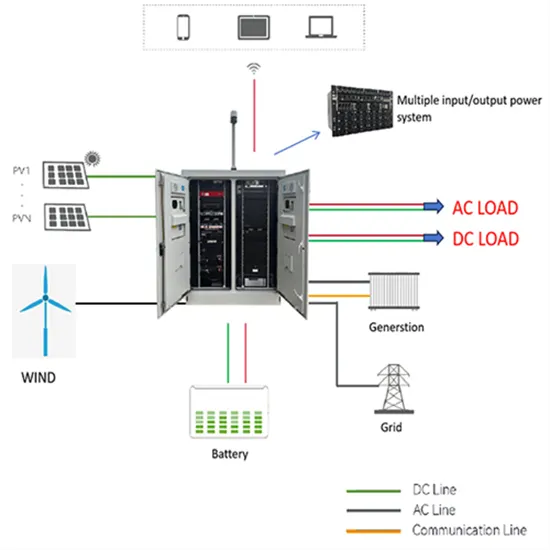

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.